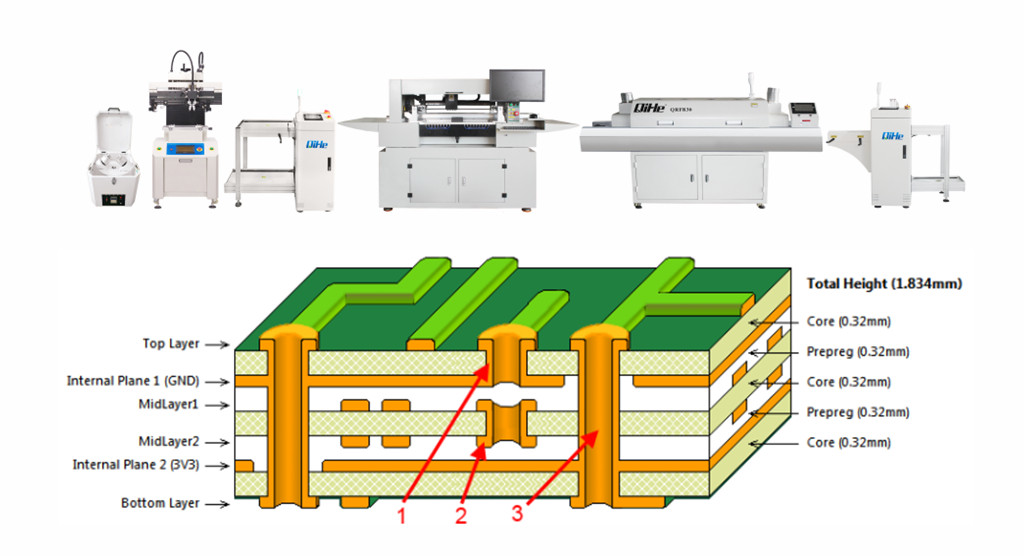

Skills about heat dissipation of PCB design in SMT process

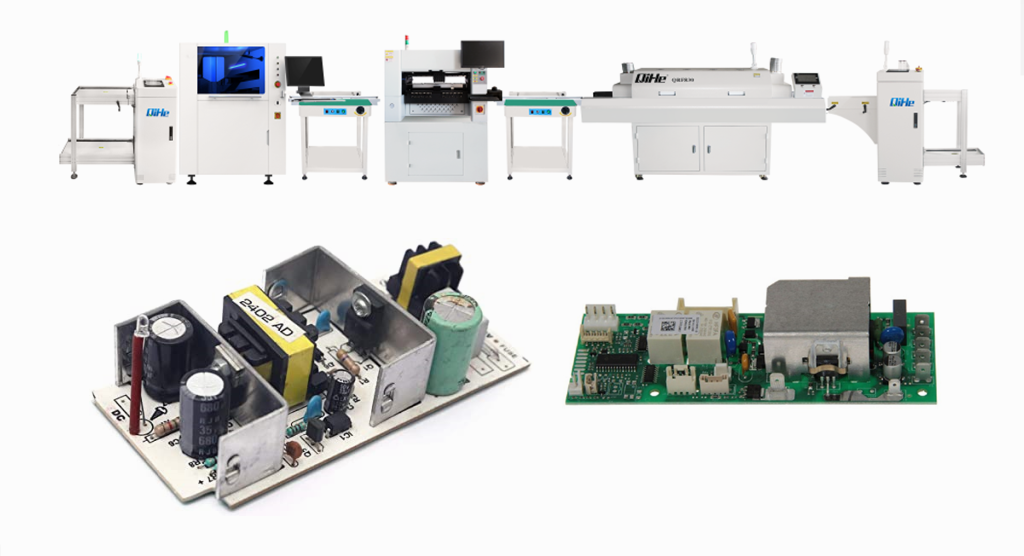

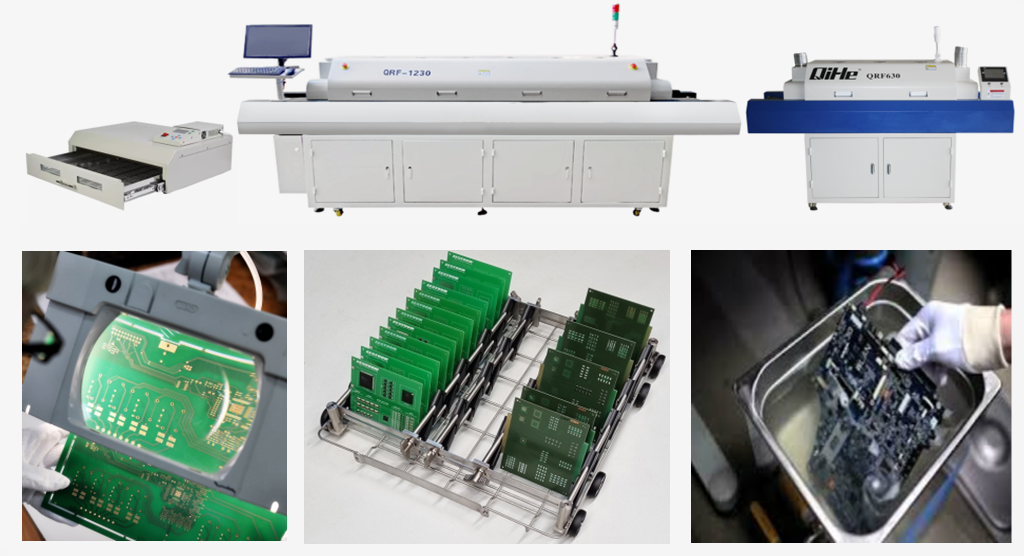

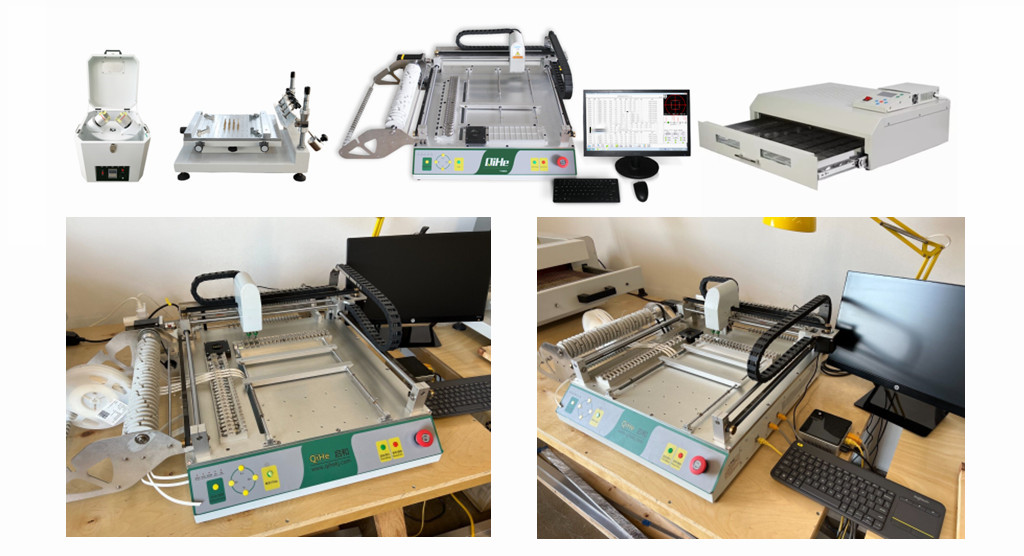

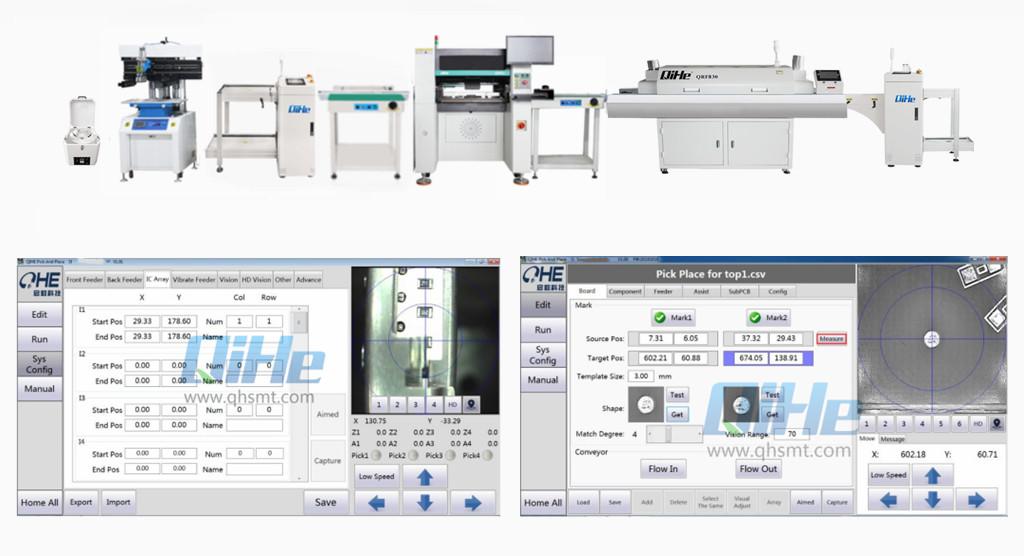

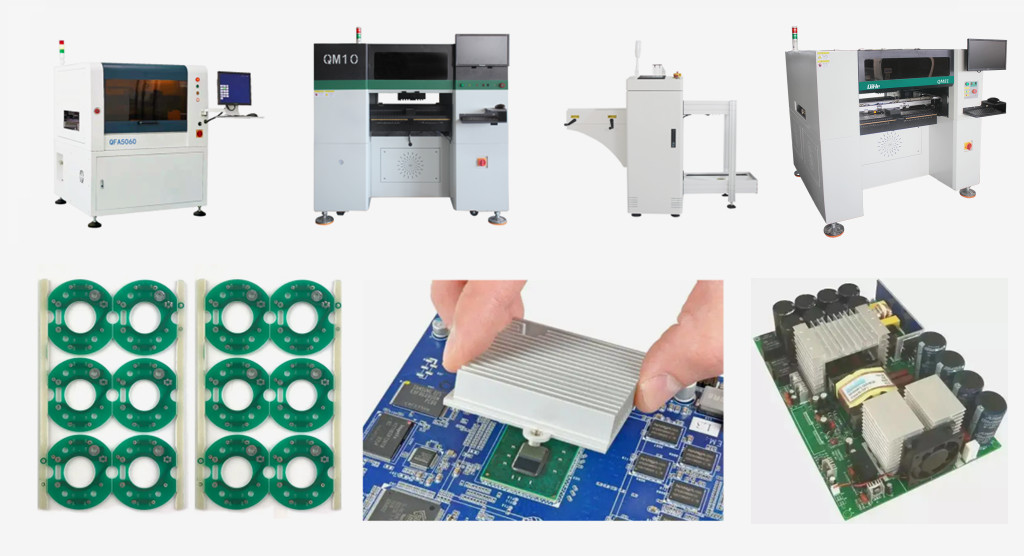

Skills about heat dissipation of PCB design in SMT process smt pick and place machine reflow oven stencil printer There are some skills about heat dissipation of PCB circuit boards before you use the smt pick and place machine. qihe smt will sharing you some tips today .