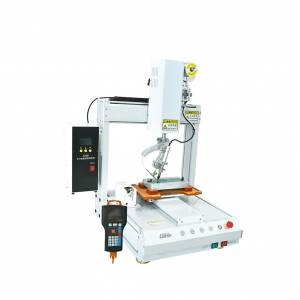

Description

QM62 SMT pick and place machine is designed for mass production or R&D proofing purpose. It contains 6 heads,50 slots .

Compared with the QM61 model, it is compact type characterized by a smaller size .Bare machine width 884mm can pass through a smaller door, suitable for offices or laboratories or even houses

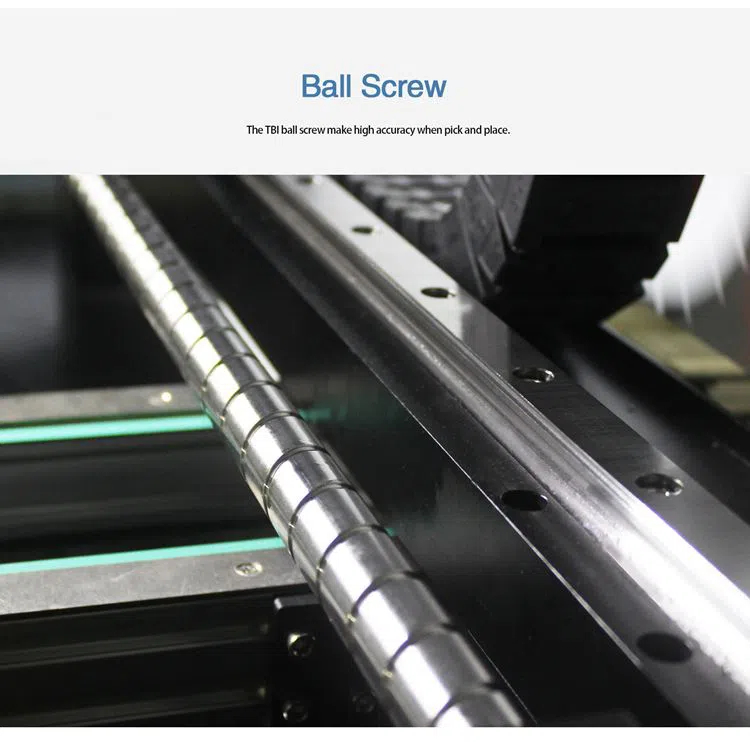

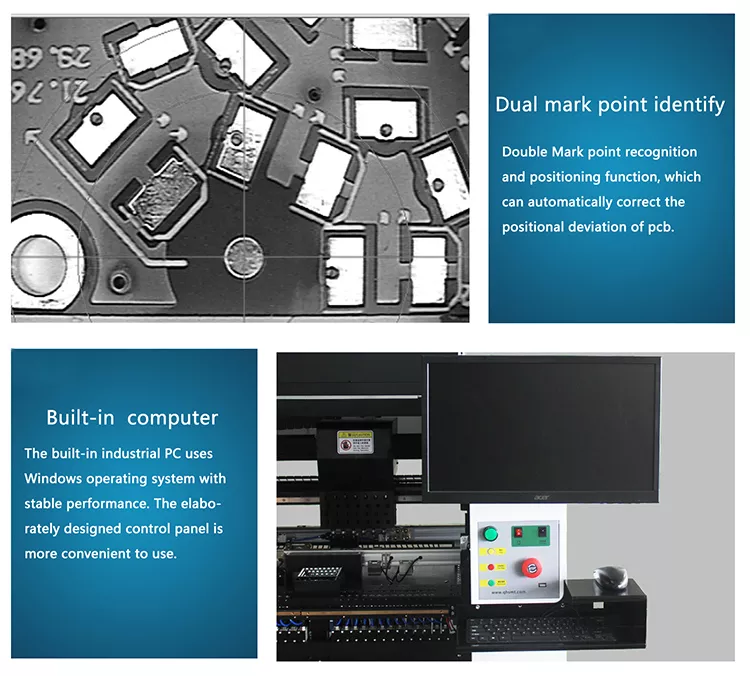

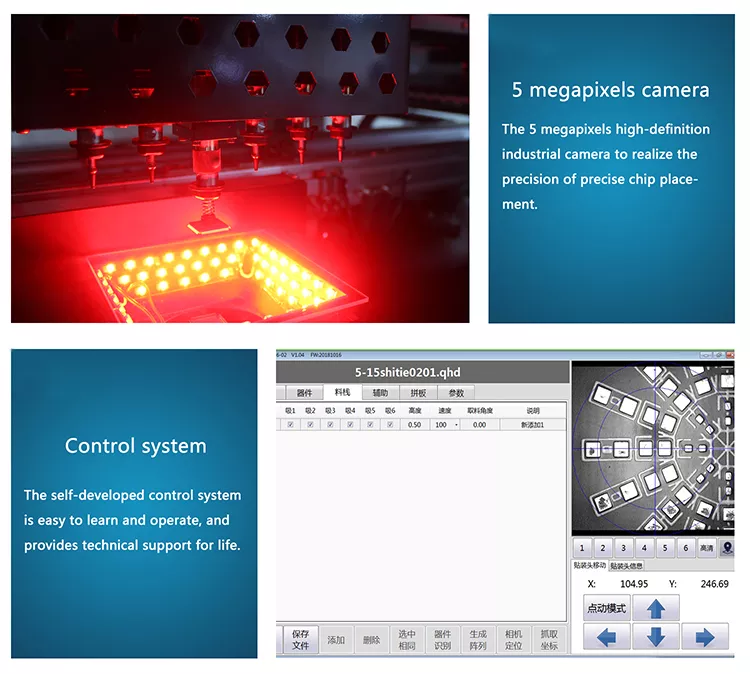

The hardware including flying shot recognition camera,the Hiwin linear rail,the TBI grinding screw,the master computer ,triple stage transmission rail system.

Upgraded the software functional such as the component library ,the visual surveillance,the safety alerts,the fault previously warning .

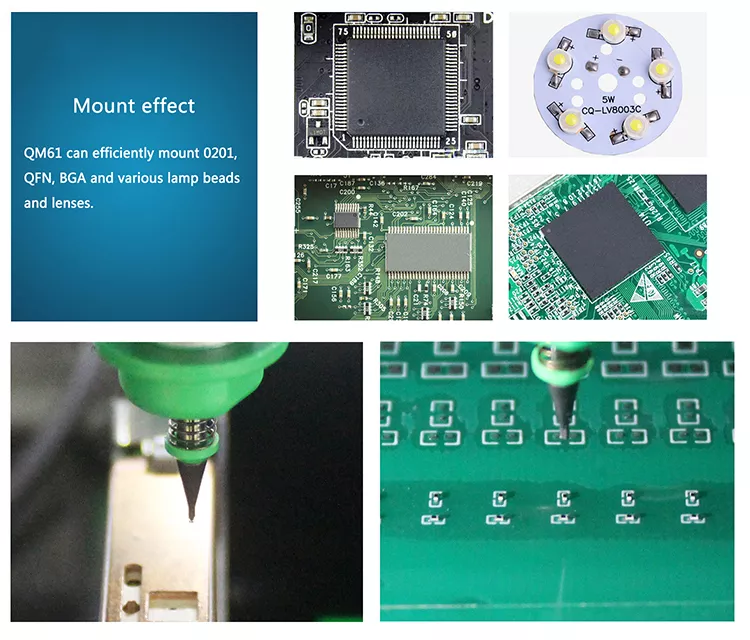

QM62 pick&place machine can easily handling special-shaped components, BGA, 0201 inch package.

QM62 chip mounter X Y axis adopts Panasonic servo motor, speed up to 15000 components per hour (CPH),

| Model | QM62 |

| Max applicable PCB size | 350*350mm |

| Max xy moving range | 730*400mm |

| Max z moving range | 32mm |

| Placement head quantity | 6 |

| Max mounting capability | Vision on: 11000pcs/h Vision off: 15000pcs/h |

| Feeder slots capability | 50 slots (YAMAHA Feeder is available) |

| Applicable component | Smallest size:0201 inch Largest size:30*30mm, pin center spacing≥0.5mm |

| Max mounting Height | 15mm |

| Visual camera | Flight HD CCD camera |

| Power | about1100W |

| Power supply | 220V |

| Net Weight | 630kg |

| Gross Weight | 690kg |

| Machine Dimension | 885*1320*1350mm |

| Packing size | 2.07CBM |