Description

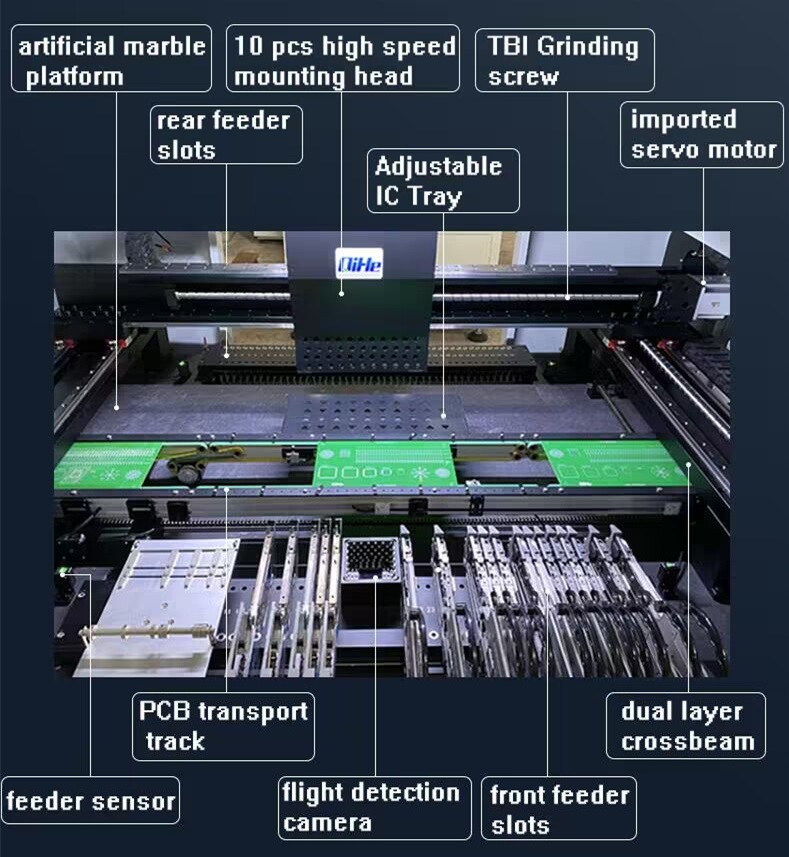

The QM10 SMT pick and place machine designed with 10heads 86slots ,QM10 pnp machine speed of up to 23000 components per hour (CPH).

It has been upgraded from the QM81 series and incorporated customer feedback.

The substrate iron plate inside the machine upgrade into thickened marble material to increase stability .

The X-axis improves the structure to increase the smoothness of operation .and increased the number of linear guides (top and bottom)

The Y-axis has also been increased into two linear guides on each side to improve accuracy and speed increase machine durable life.

Even the model of Panasonic servo motor, driver, linear guide, and screw have been completely upgraded to cope with the working capacity of 10 heads .

Upgraded the software functional such as the component library ,the visual surveillance,the safety alerts,the fault previously warning .

Can easily handling special-shaped components, BGA, 0201 inch package.

X Y axis adopts bigger Panasonic servo motor, without sacrificing the CPH rate with high troque to achieve never lost step accuracy < 0.001mm.

new features like 10 heads take material at the same time,

Components size shoud be 0805 inch and above size , like 3535 LED lamp beads .

( suggest use the electric feeder to avoid the problem of insufficient air supply)

| Model | QM10 |

| Max applicable PCB size | 60*60~330*750mm |

| Max xy moving range | 670*730mm |

| Max z moving range | ±15mm |

| Placement head quantity | 10 |

| Max mounting capability | Vision on: 17000pcs/h Vision off: 23000pcs/h |

| Feeder slots capability | 86 (YAMAHA Feeder is available) |

| Applicable component | Smallest size:0201 inch Largest size:22*22mm including 0201~5050,sop,LQFP,QFN,BGA,etc. |

| Max Height | 15mm |

| Visual camera | Five megapixels HD CCD Flight camera |

| Power supply | 220V |

| Net Weight | 1600kg |

| Gross Weight | 1750kg |

| Machine Dimension | 1500*1735*1620mm |

| Packing size | 4.21 CBM |

What is SMT in engineering?

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,and other products.

Small desktop pick and place machine TVM802A,TVM802B,TVM802AX,TVM802BX series suitable for beginners, for hobbiest or low vol usag.

Advanced level 4-head LED strip placement QL41 led machines and with rail universal series TVM925S,TVM926S,

Fully automatic 6-10-head placement QM61,QM62,QM81,QM10,machines, which are suitable for high volume mass production in factories.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/