Description

Q10 automatic pick and place with 10 head, 100 feeders slots, Panasonic servo,Flight camera, ball screw, Q10 pnp machine, speed of up to 27000 components per hour (CPH) ,applied for all levels of PCB and LED assembly .

The Q10 SMT pick and place machine is upgraded from the QM10 series with customer feedback. It is designed with 10 heads and 10 slots, the Q10 pnp machine has a speed of up to 27,000 components per hour (CPH).

The interior of the machine has been upgraded from the traditional aluminium plate to marble material, so that the machine will not be shifted out of position during movement due to its light weight, and the accuracy will be higher, and the service life of the guide rail of the screw has been enhanced to make the machine more stable at high speeds.

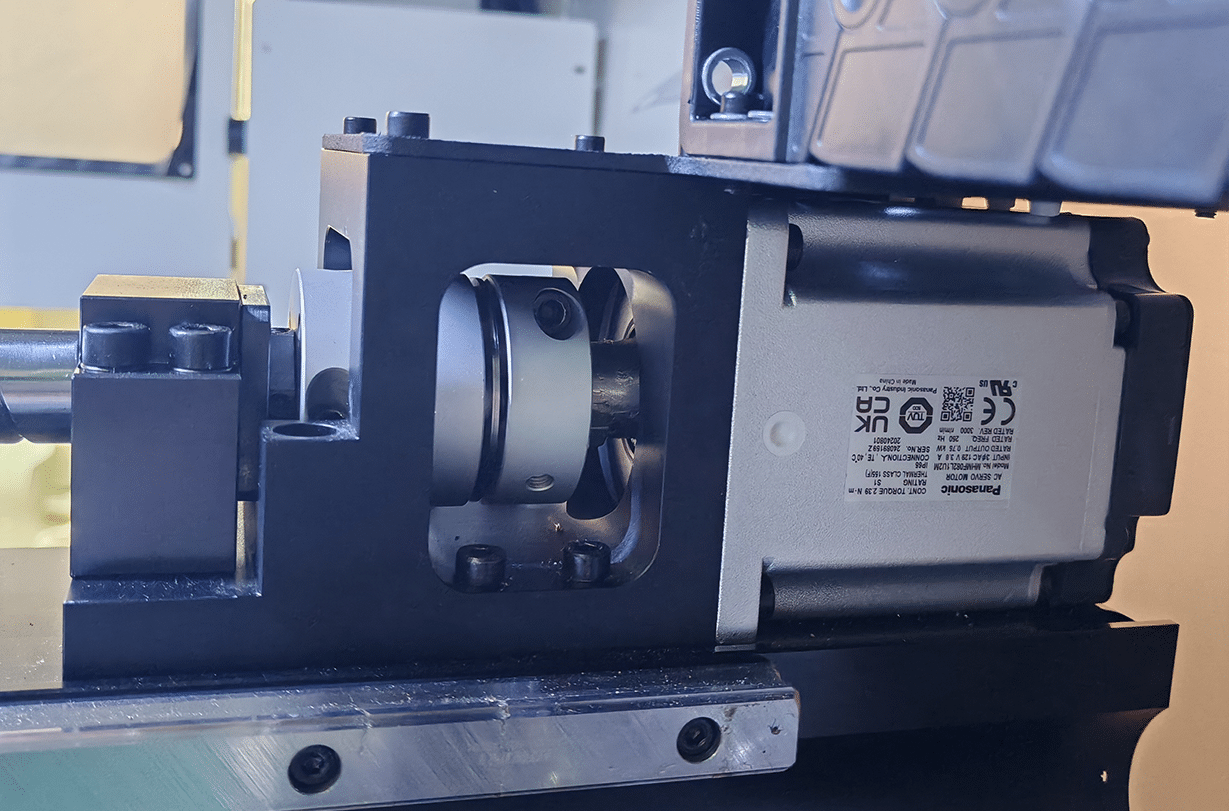

Z-axis adopts servo motors, 10 suction nozzles correspond to 10 servo motors, high precision movement, position, speed and torque of the closed-loop control, so that the clamping is more accurate, servo motors with high speed, high speed performance, the rated speed of up to 3,000 rpm, or even faster!

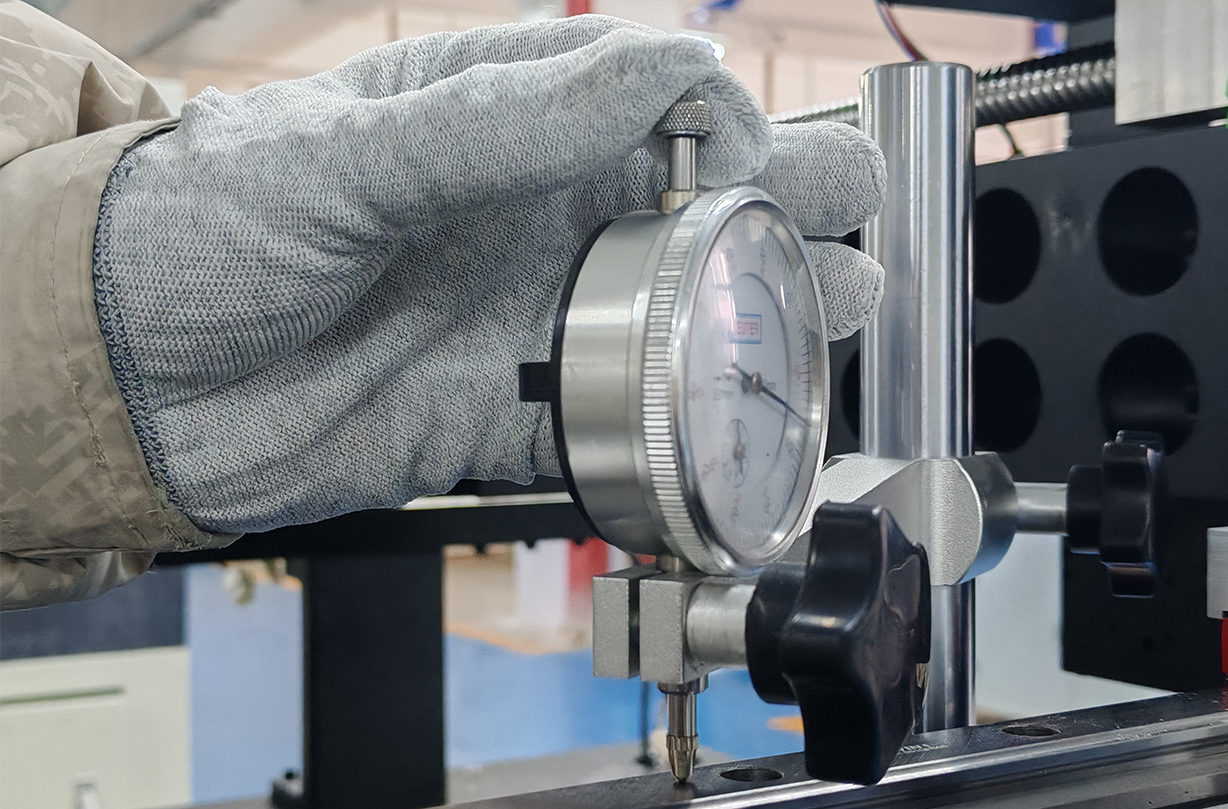

X Y-axis adopts larger Panasonic servo motor, without sacrificing the CPH rate, to achieve the precision of mounting accuracy < 0.001mm.

It also upgrades the software functions, such as component library, visual monitoring, safety alarms, and fault warning.Easily handles shaped components, BGAs, and 0201-inch packages.

New features such as simultaneous pickup of 10 heads.

Component size should be 0805 inch and above, such as 3535 LED beads.

(Motorised feeders are recommended to avoid problems with insufficient air supply).

| Model name | Q10 | |

| Substrate size | 20mm×50mm~350mm×500mm0Q(1.5)(Customizable for 1.5 meters)Q100Q10 | |

| Maximum movement range of the XY axis | 800mm×710mm | |

| Maximum movement range of Z-axis | 32mm | |

| Number of mounting heads | Lightweight 10-nozzle mounting head | |

| Fastest speed | 27000cph(0.13s/chip) | |

| Average velocity | 16000cph(0.22s/chip)~21000cph (0.17s/chip) | |

| Installation accuracy(cpk≥1) | ±40μm/chip | |

| Maximum mounting height | 15mm | |

| Component angle support | 0-360°0-360°At any angle,rotate synchronously during motion | |

| Applicable components | Resistance and capacitance:0201~5730,diode,transistor | |

| chip):LQFP、QFN、QFP、BGA(spacing)≥0.3mm | ||

| (led):0402~5070、(Anti lumen,lens) | ||

| Maximum mounting ICsize | 33mm×33mm | |

| Componet supply | Braiding | Bandwidth coding):4/8/12/16/24/32/44/56mm |

| Specifications of front and rear feeders:Max100 varieties(4,8mm braided tape,small reel) | ||

| Tubular | Specification of front and rear feeders:Max30 variety(three tube vibration Feida) | |

| Tubular | Max96(IC) Max 96 variety (IC tray) | |

| Axis drive motor | Panasonic servo motor | |

| Z-axis drive motor | Servo motor | |

| Guide rail drive motor | Stepper motor | |

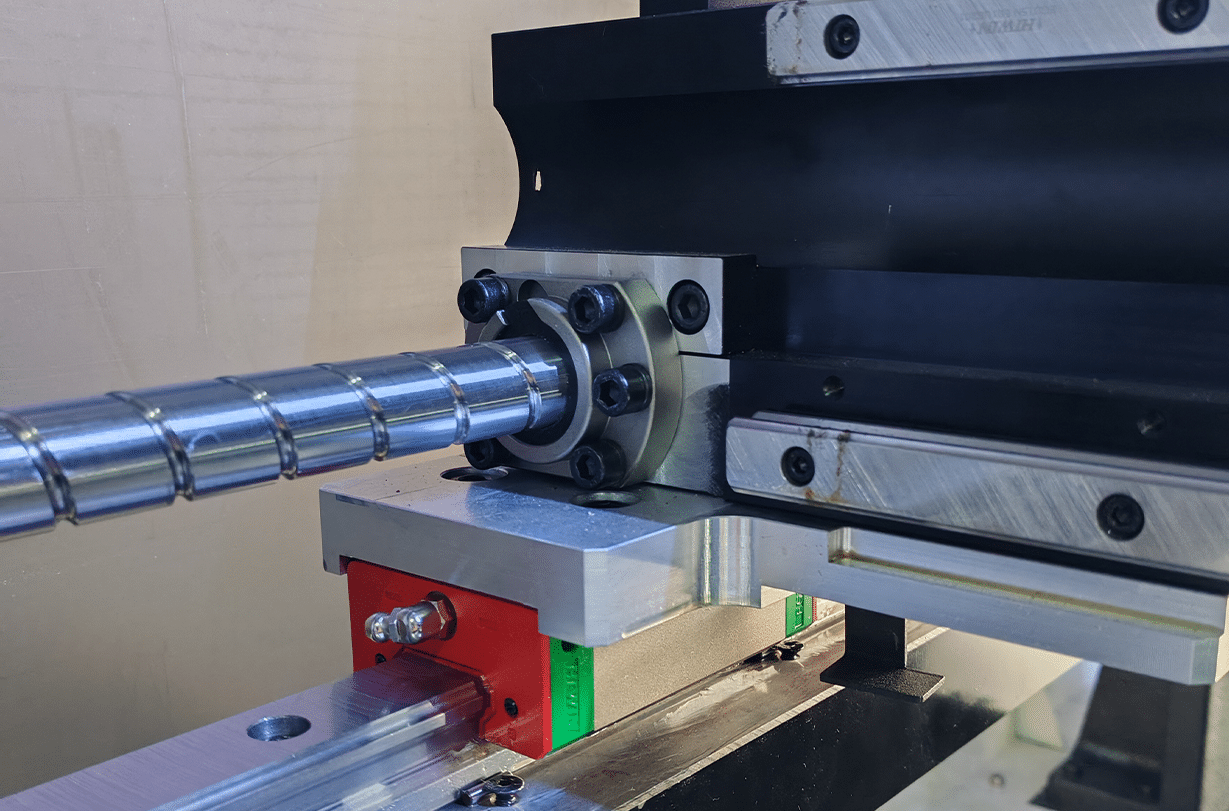

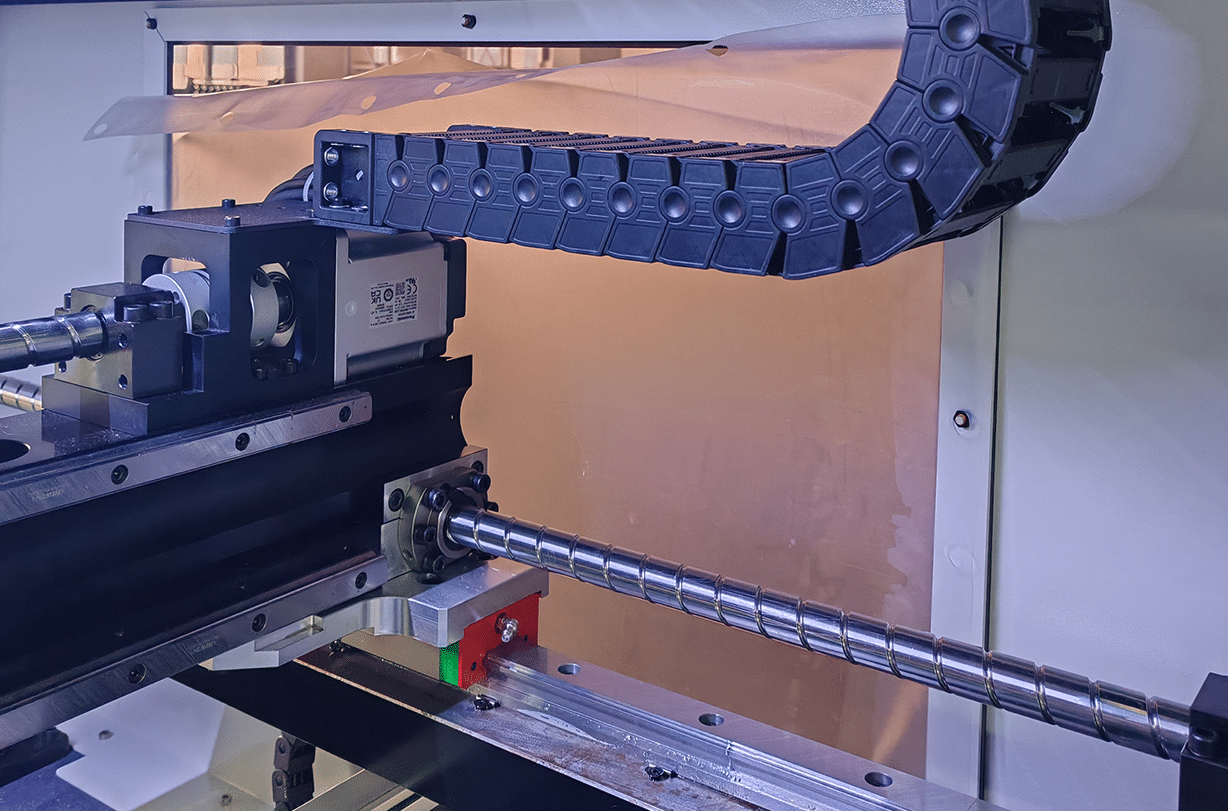

| Transmission mode | TBl high-precision ball screw | |

| XY axis drive guide rail | Shangyin HIWIN high-precision linear guide rail | |

| XY operating model | Intelligent curve acceleration and deceleration linear linkage,with built-in linear interpolation algorithm | |

| axis drive guide rail | Yadeke high-precision linear guide rail | |

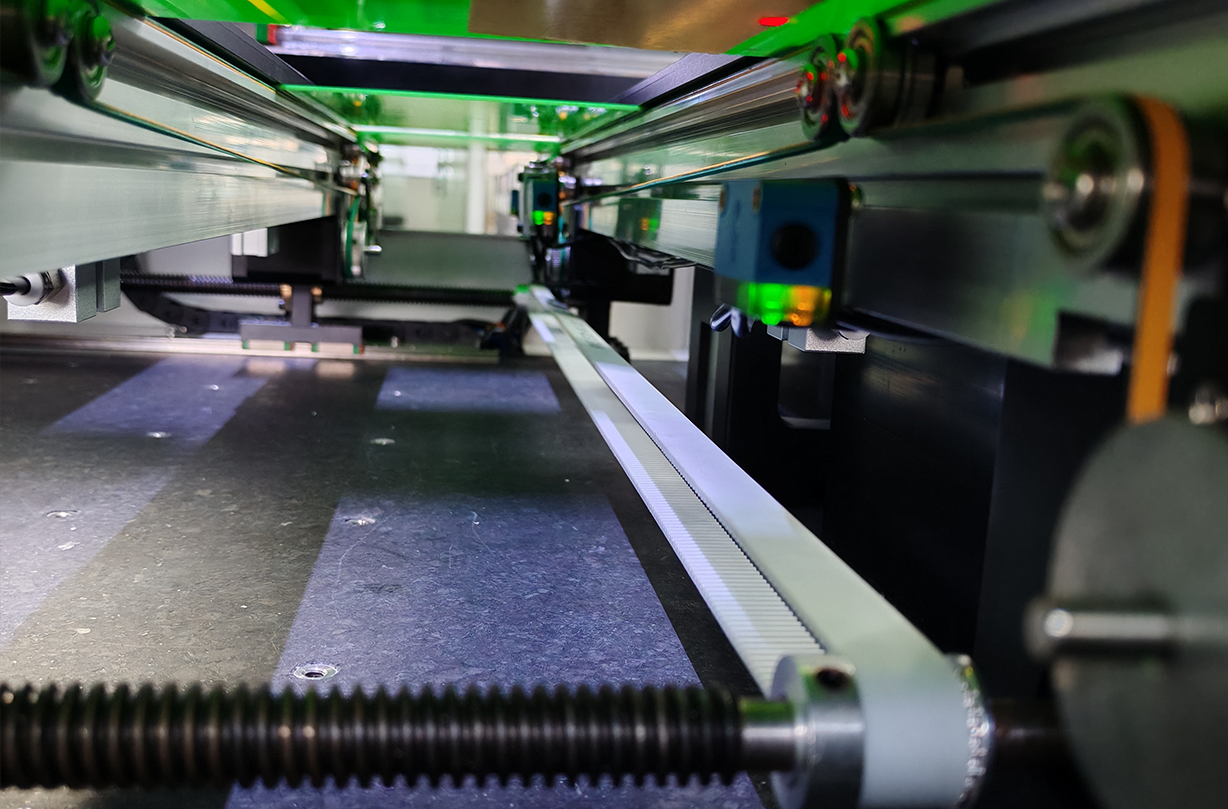

| Upper visual | 1 high-definition frequency precision high-speed recognition aerial camera | |

| Lower vision | 2 Mark high-precision cameras | |

| PCB transmission method | Three section transmission connection from left to right, automatic PCB transmission and positioning | |

| Track adjustment method | Motor drive | |

| Number of feeders | 100 (front 50 and back 50) | |

| Type of feeder | Yamaha Electronic Fit,Pneumatic Fit,Three tube Vibration Fit,Five tube Vibration Fit,8,12,16,24,32mm Fit,etc. | |

| driving system | Panasonic High Speed DSP Drive | |

| control system | Q10 Release,a self-developed Q10 fully automatic SMT machine operating system by Qihe | |

| operating system | Supports Windows XP and Win7 operating systems | |

| Leakage detection | Visual inspection | |

| Support PCB design software | Coordinate files exported from Protel, DXP, Altium Designer, Pads, Candes, and Proteus in CSV, txt format. | |

| Average power | =1.2KW | |

| power | AC220V | |

| Air pressure source | External air source(min0.5MPa,200L/min(A.N.R.) | |

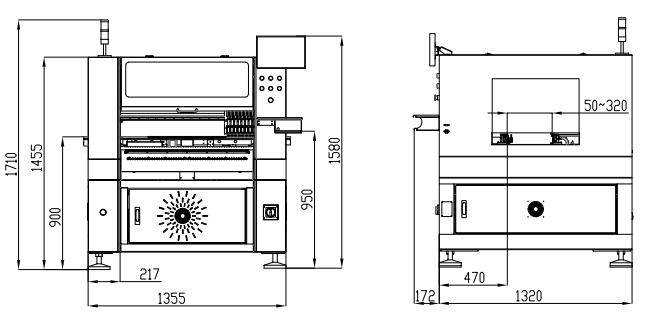

| Equipment size | W1350mm*D1320mm*H1450mm | |

| Weight | 1025KG Subject only:varies depending on the composition of the optional parts) | |

- Functional Features

1. Fully automated online design reduces the cost of manual loading and unloading.

2. Ten Z-axis cameras fly simultaneously to further optimize the device’s mounting mode and response speed.

3.Circuit control system, fully integrated mode, with clear indication of electrical control performance.

4.The small spacing mode of the head module further improves the efficiency of surface mounting.

5.Close range waiting mode allows PCB boards to reach the mounting position more efficiently.

- Application scope

All products within 400*380mm, including bulb lights, tube lights, spotlights, ceiling

lights, guardrail tubes, LED driver power supplies, linear lights, soft light strips, control

boards, and car lights,etc.