Description

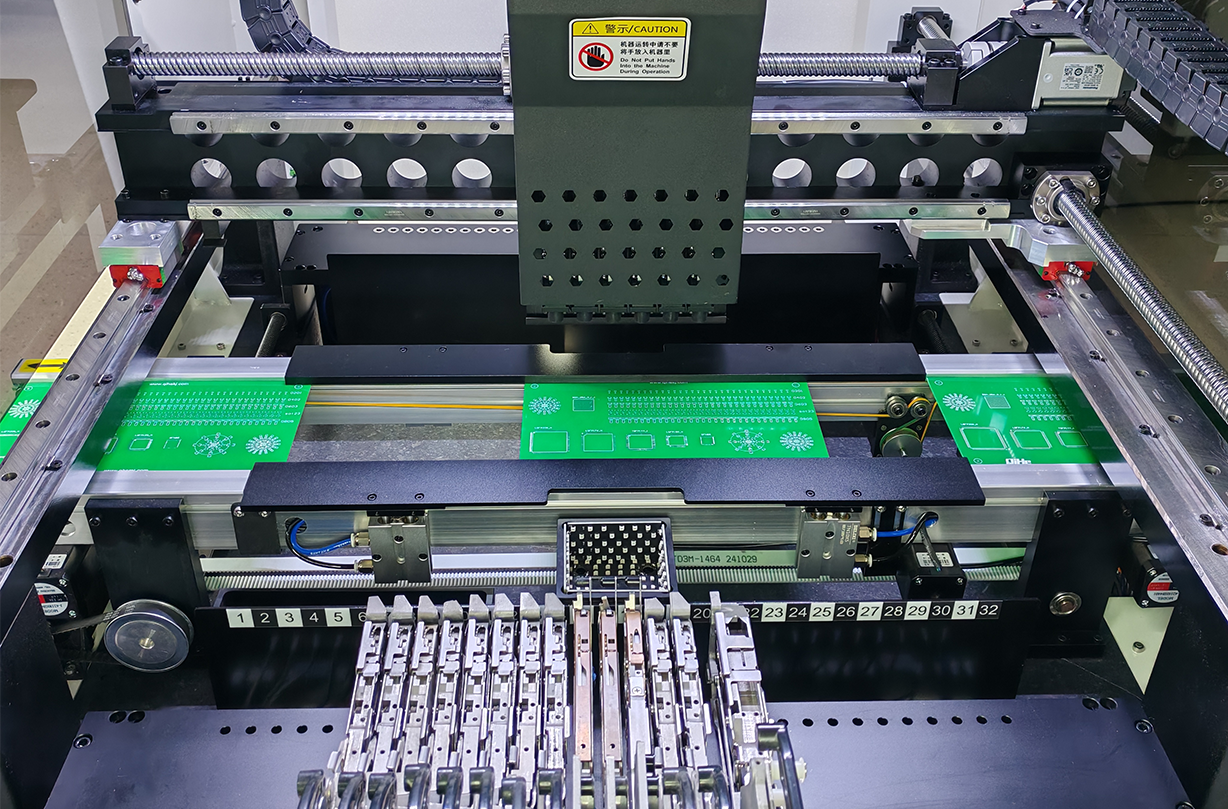

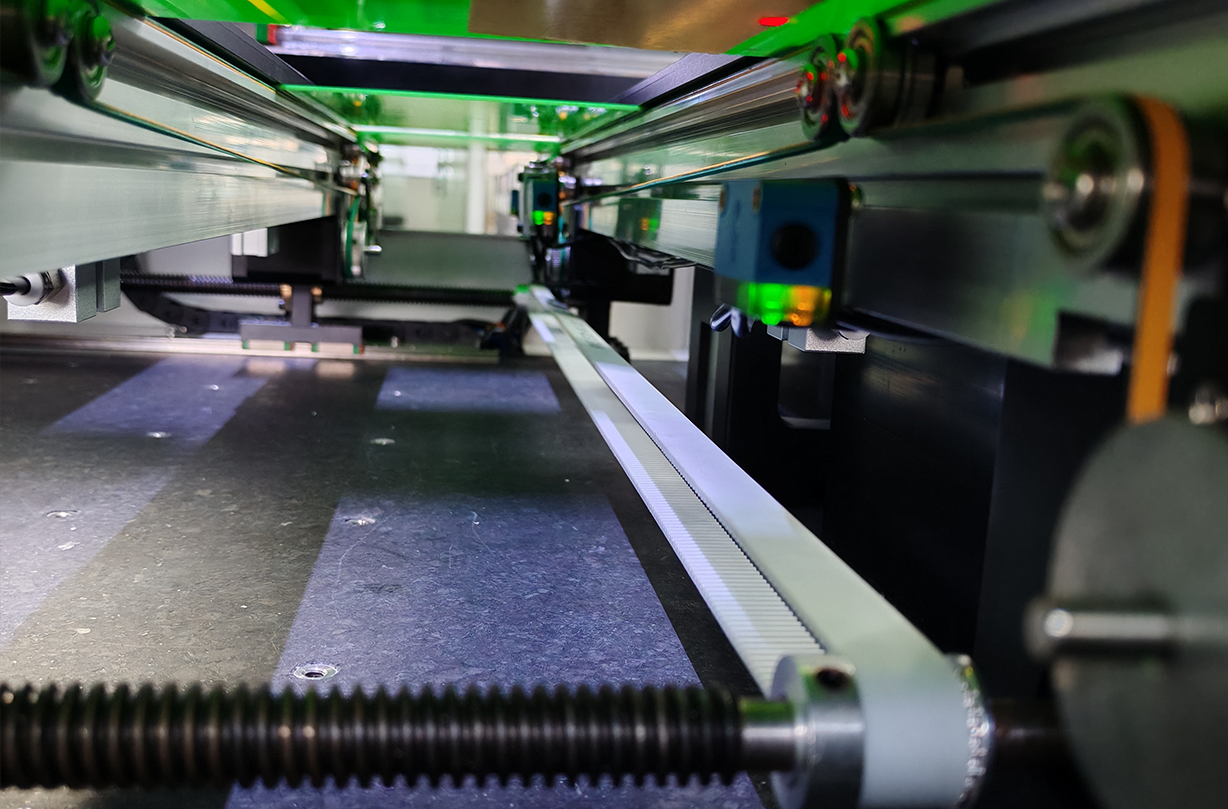

Qihe Q6 smt pick and place machine adopts a new design 6 Pick & Place working nozzles with fully automatic railguide.Q6 pnp machine top speed up to 17000 components per hour (CPH)

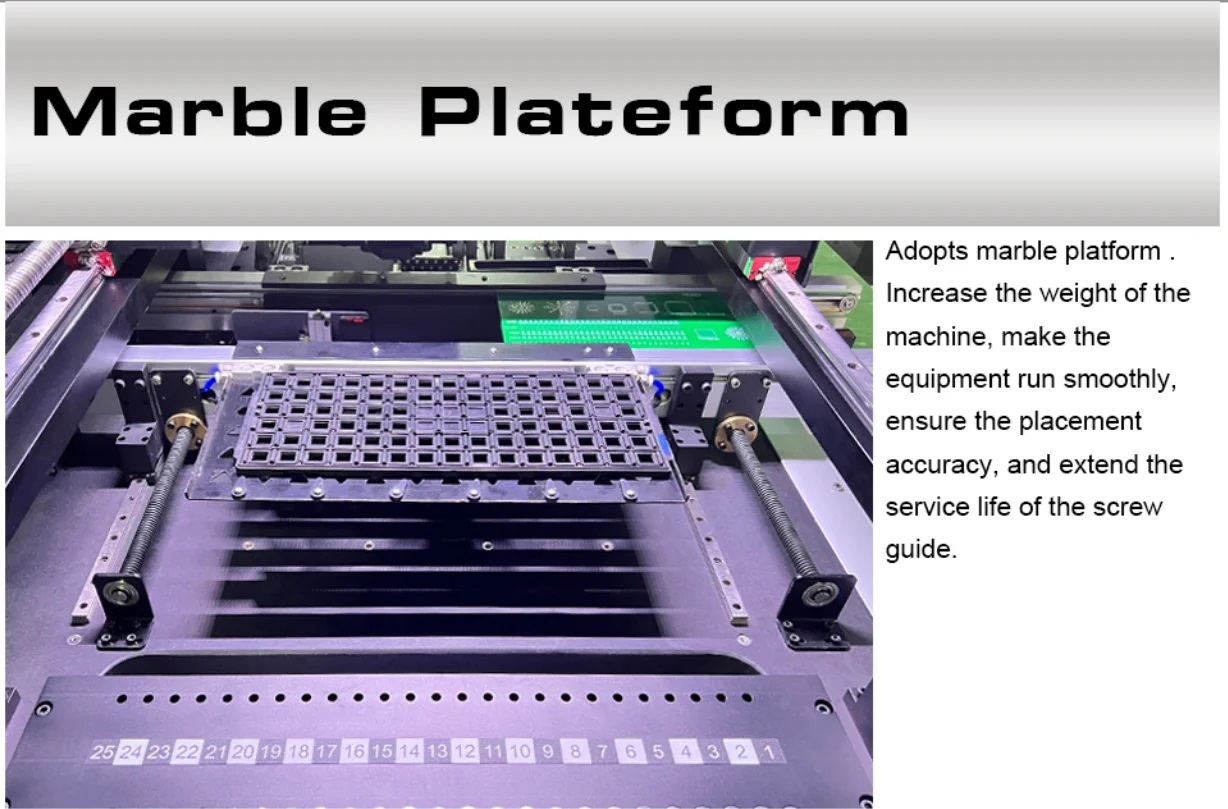

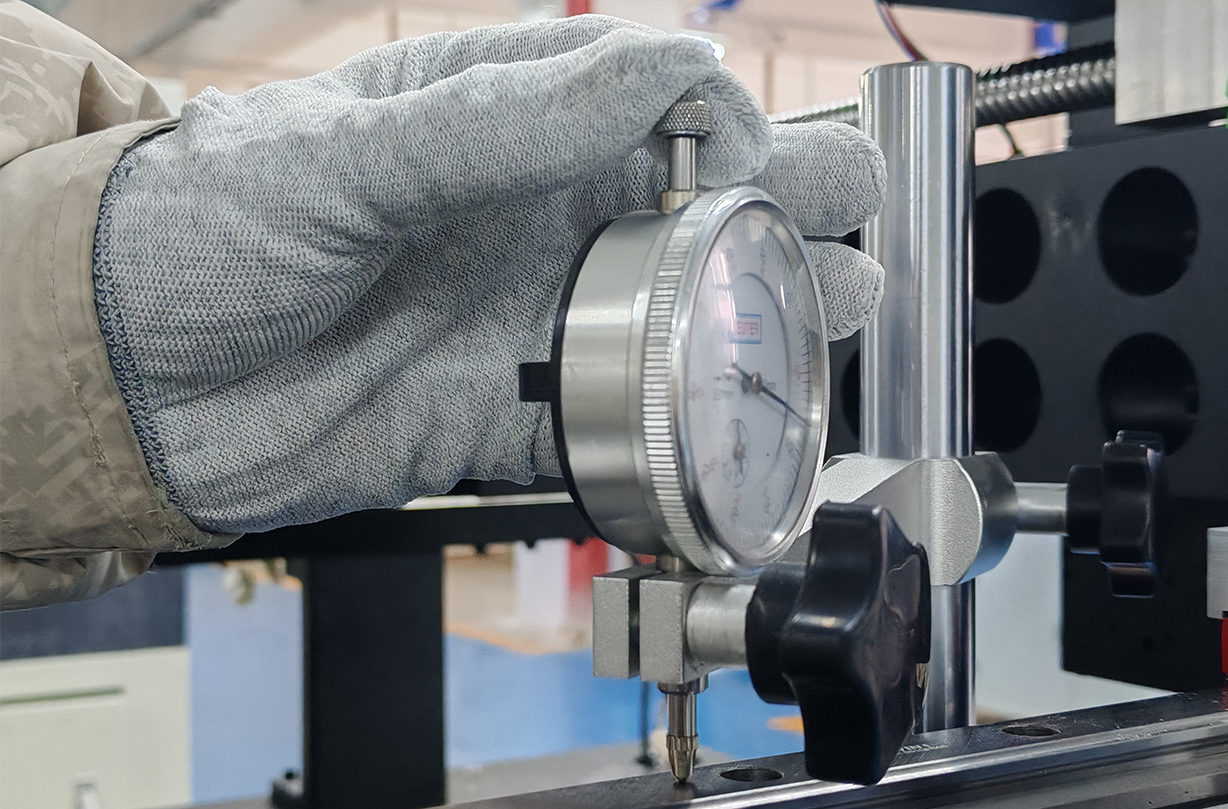

Newly upgraded the hardware like the highspeed global shutter flight camera,the servo driver and motor,the TBI screw rod,and the automatic transfer rail .The substrate iron plate inside the machine upgrade into thickened marble material not only increase stability but also improve the accuracy of the working head during high-speed movement .

Q6 pick and place it’s customizable which can support LED strips reach 1.2meters .

Observation windows are added on both left and right sides of the machine, allowing the operator to observe the operation of the equipment from multiple angles and facilitating subsequent maintenance.

The newly designed keyboard integrated stand tray is more ergonomically designed and can be adjusted at multiple angles according to the smt operator’s habits, replacing the traditional fixed stand.

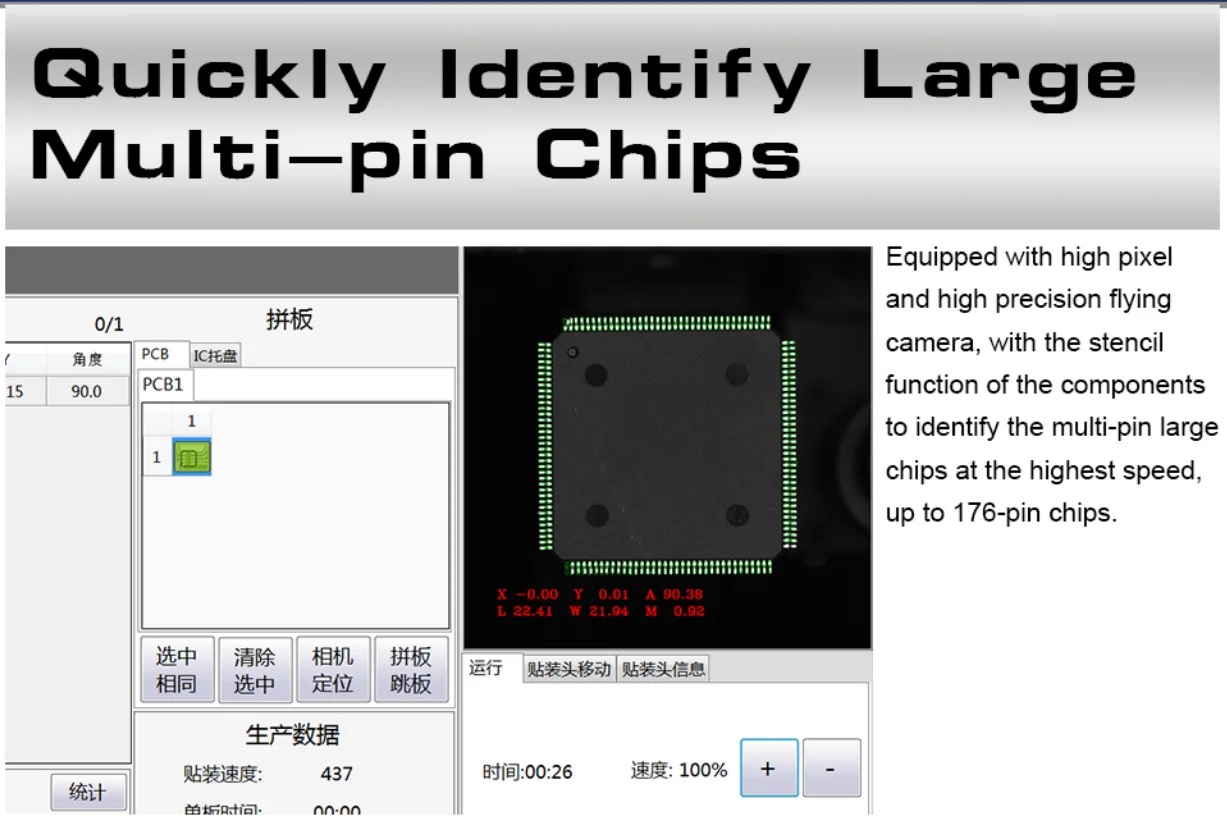

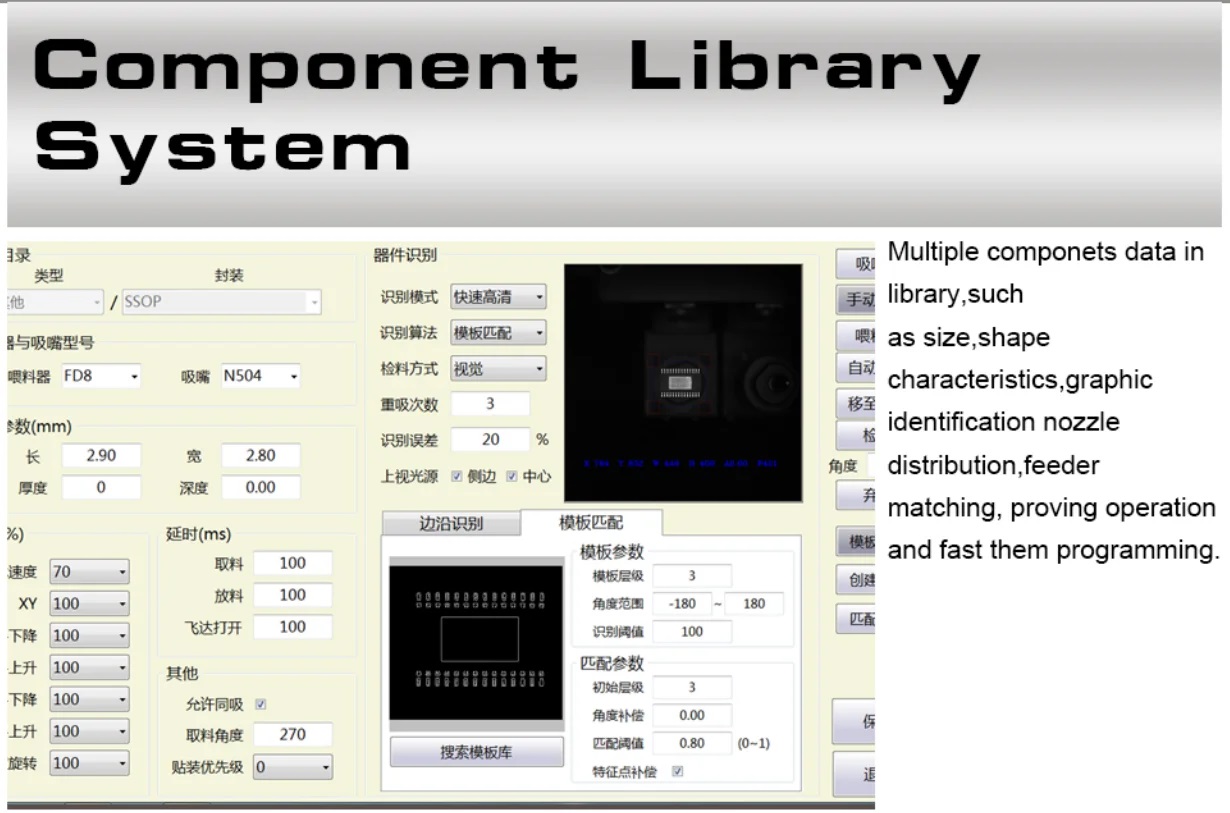

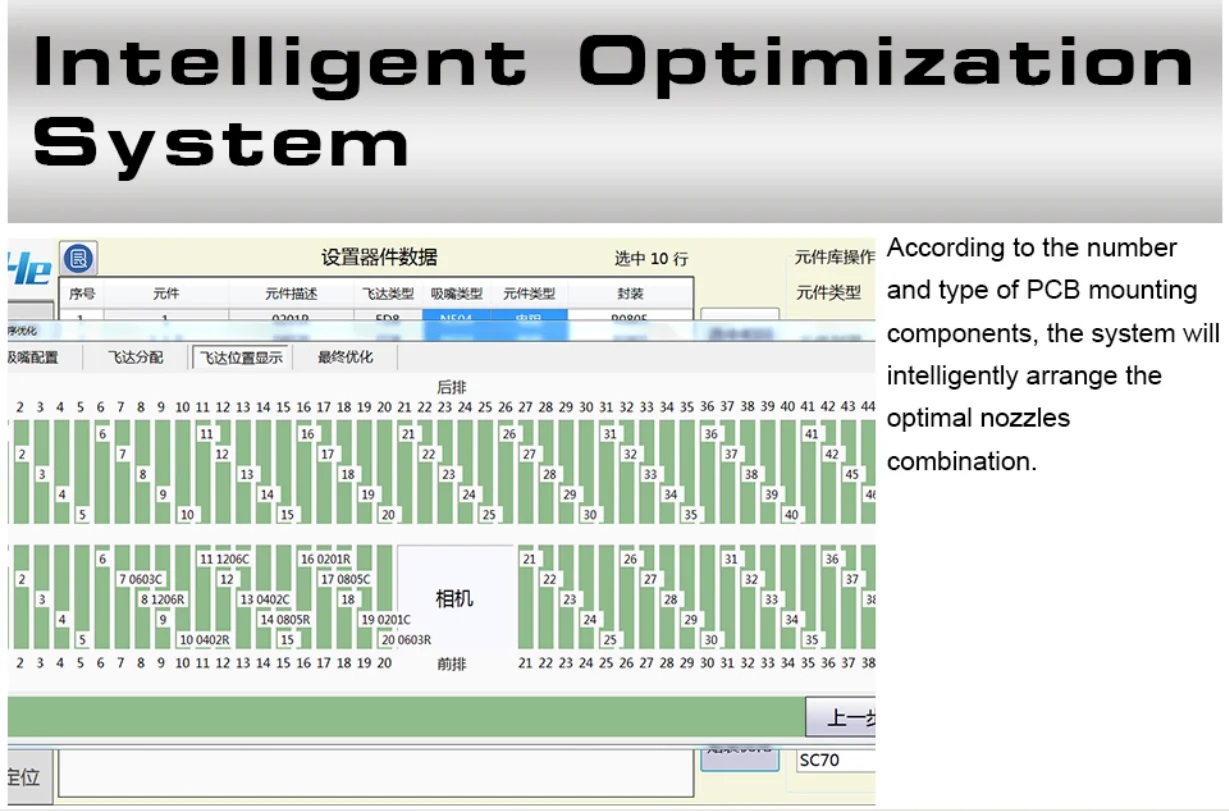

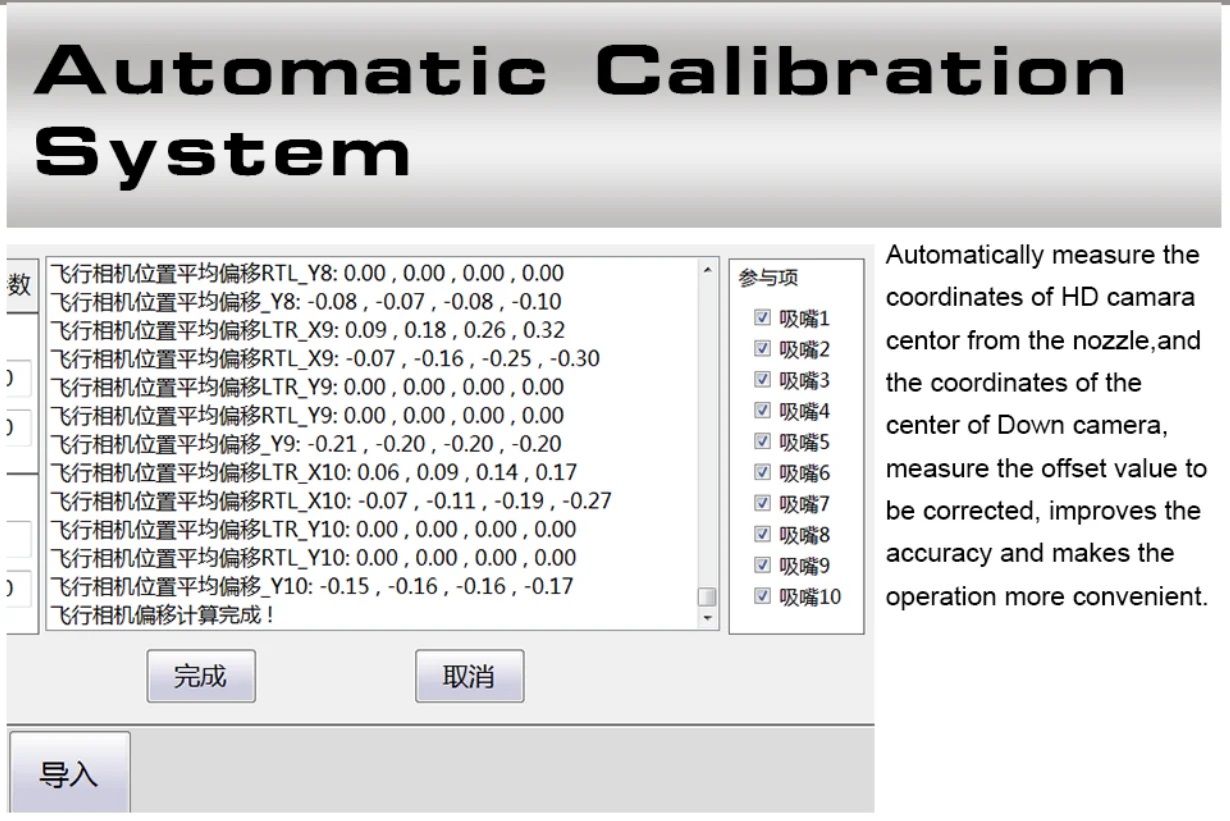

Upgraded the software functional such as the component library,the visual surveillance,the safety alerts,the fault previously warning .

Can handling Anti-lumen,Lens, and components like LQFP,QFN,QFP,BGA spacing≥0.3mm, 0201 inch package.

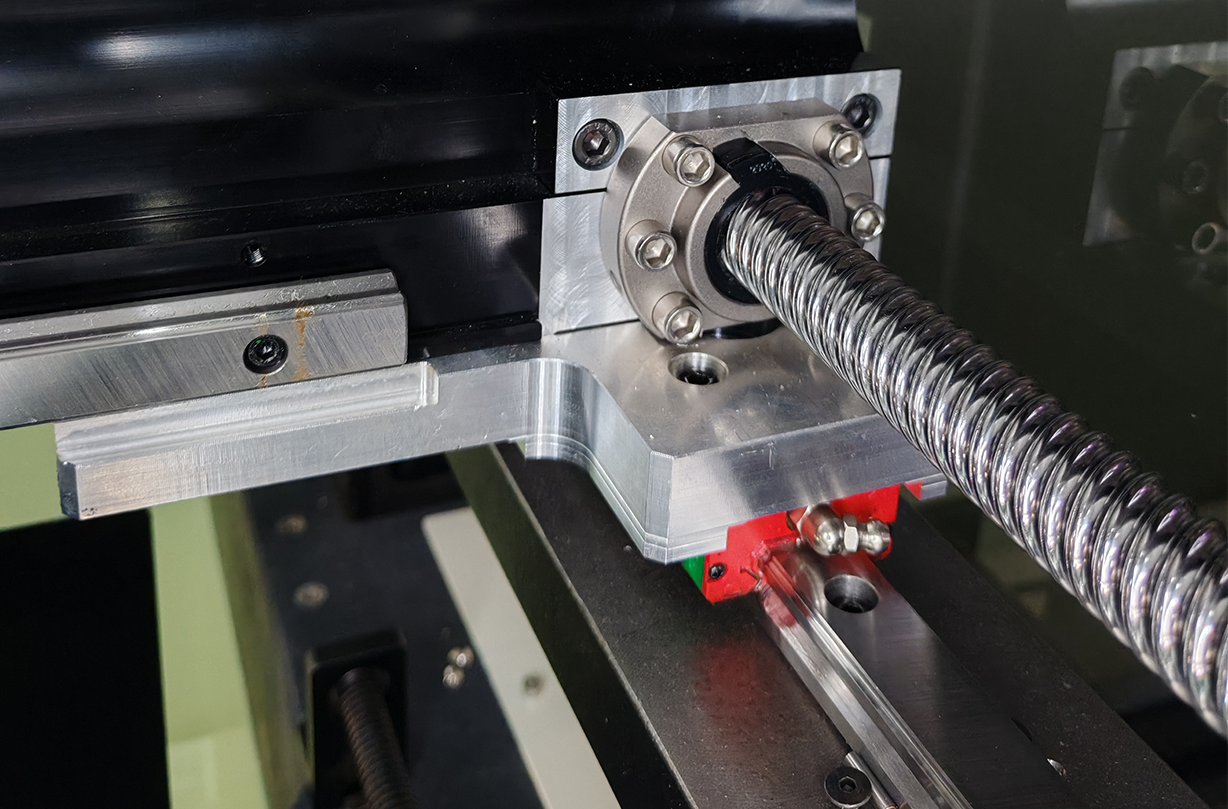

Q6 pick and place machine X Y axis adopts Panasonic servo motor, top speed up to 17000 components per hour (CPH).

| Model | Q6 |

| Max applicable PCB | 20*50mm~350x600mm(1.2m customizable) |

| XY moving range | 500*700mm |

| Z moving range | 32mm |

| Placement head quantity | 6 |

| Optimal speed | 17000cp(0.21s/chips) |

| Installation speed(vision) | 10000cph(0.38s/chips)~15000(0.24s/chips) |

| Placement accuracy | ±40 μm/Chip |

| Max placement height | 15mm |

| component angle | 0~360 ° arbitrary angle,synchronized rotation in motion, |

| Applicable components | Resistor:0201~5730 inch,Diode,Triode IC Chip:LQFP,QFN,QFP,BGA spacing≥0.3mm LED: 0402~5070 inch,Anti-lumen,Lens |

| Max IC size | 33mm*33mm |

| Components package type | Strip: width:4,8,12,16,24,32,44,56mm Materials specification:Max 64(4/8mm strip,roll) Tube: Materials specification:Max 24(3 tube vibration feeder) Tray: Max96(IC tray) |

| Movement Control System | XY axis : servo motor, Panasonic brand Z axis : Step motor Track : Step motor |

| XY transfer mode | High precision screw ball ,TBI brand |

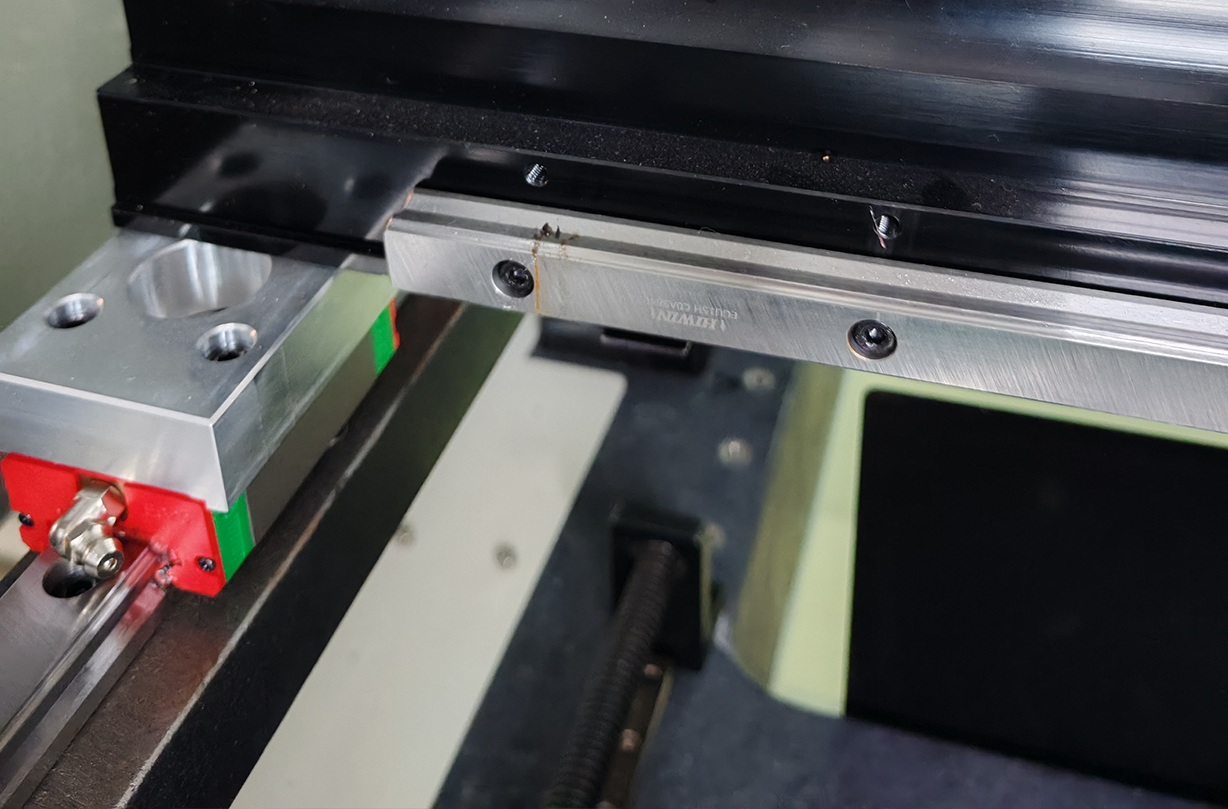

| XY axis drive guide rail | High precision linear track,HIWIN brand |

| XY operation mode | Intelligent curve acceleration and deceleration linear linkage with linear interpolation algorthm |

| Z axis drive guide rail | High precision linear track,Airtac brand |

| Feeders loading ability | 50 slots (front 25 rear 25) based on 8mm width reel tape |

| Support Feeder type | Electrical/pneumatic 8mm,12mm,16mm,24mm,32mm, 3/5 tube channel vibration feeder (YAMAHA type Feeder is available) |

| Visual camera | 1 HCD PCB inspection camera , 1 highspeed global shutter flight camera |

| Visual camera(down) | Automatic identify the mark point |

| Visual camera(up) | Automatic adjust the offset |

| PCB transfer direction | Left→Right one stage |

| Track adjustment | Software operation, automatic electric adjustment |

| Driver system | SDP Panasonic high driver |

| Control system | QIHE Q6 automatic pick and place operation system |

| Operation system | Win10,win 7 |

| Inspection system | Visual inspection (Material shortage detection) |

| Support file format | Format csv,txt . the coordinate files exported from PCB design software:(Protel,DXP,Altium Designer,Pads,Candes,Proteus,) |

| Air supply | External air pump,min 0.5MPa,200L/min(A.N.R.) |

| Power supply | AC220V/110V , 50/60Hz |

| Average working Power | Approx 1.2KW |

| Gross weight | 880KG |

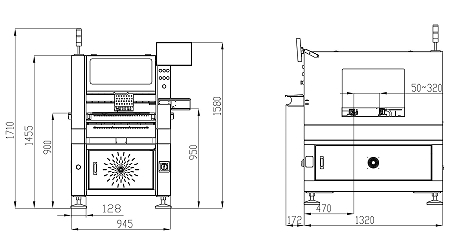

| Machine dimension | L945xW1320xH1710mm |

| Packing size | 2.8CBM |