Description

Spot welding process for the opening of the cooling water; the surface of the weldment cleaned, assembled accurately, sent to the upper and lower electrode between the pressure to make good contact; energised so that the two workpiece contact surface heat, local melting, the formation of nuclei; power off to maintain the pressure, so that the nuclei in the pressure of the cooled solidification of the formation of welded joints; remove the pressure, remove the workpiece. Welding current, electrode pressure, energisation time and electrode working surface size and other parameters of the spot welding process have a significant impact on the welding quality.

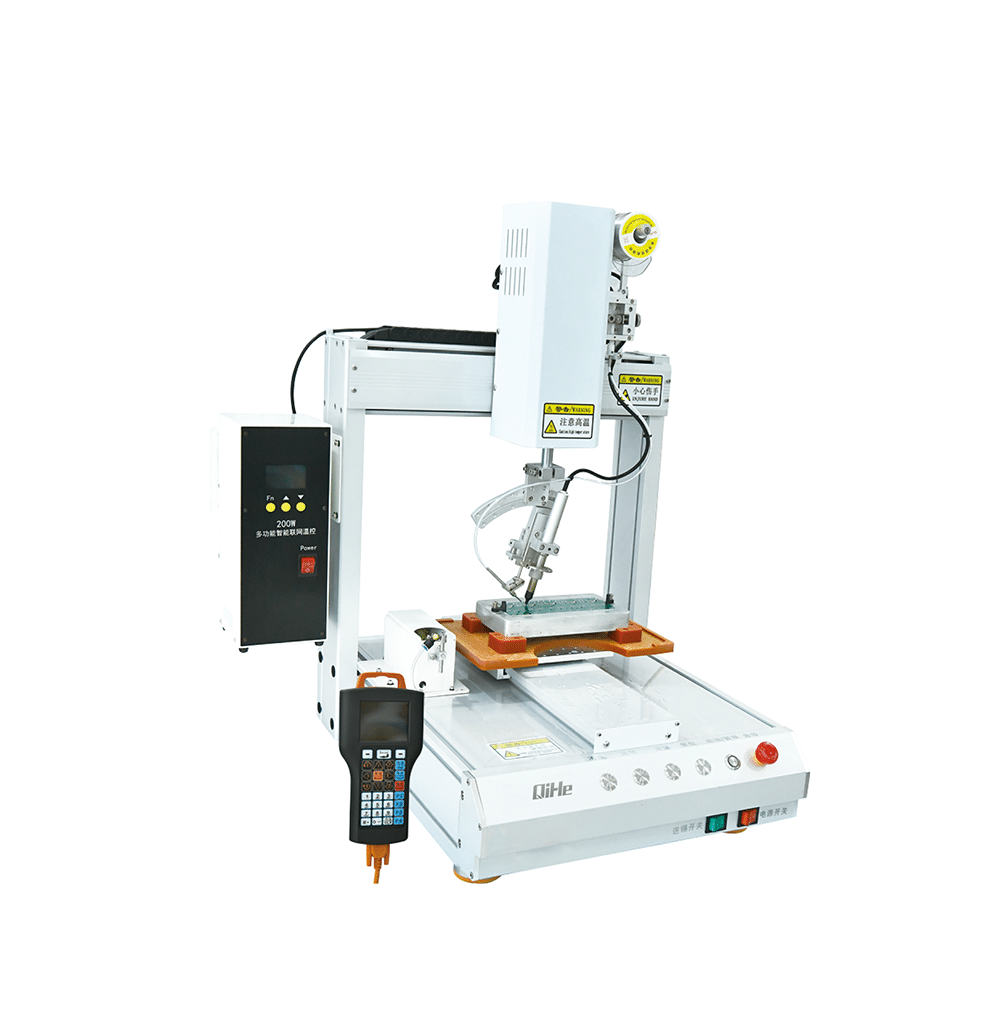

| Model | QH-ASM331R | QH-ASM441R |

| Moving Range of X/Y/Z/R(mm) | 300/300/100/360° | 400/400/100/360° |

| Maximum production size(mm) | 280*280 | 380*380 |

| Heating power | 150W/200W | |

| Temperature range | 25-550℃ | |

| Temperature control accuracy | ±2℃ | |

| Moving speed(mm/s) | X/Y/Z:0-500mm/sR:0-720°/s | |

| Repeated accuracy(mm/Axis) | ±0.02 | |

| Maximum load(kg) | 10 | |

| Programming method | Teaching box | |

| Control system | Single-Chip Microcomputer | |

| Driving mode | Stepping motor +belt or Servo motor + ball screw | |

| External control port | RS232 | |

| Machine size(mm) | 660*580*800 | 770*680*800 |

| Machine weight(kg) | 54 | 58 |

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/