What is SPI?

SPI, or solder paste printing inspection, is a detection technology in the SMT production process. It is mainly used to detect the solder paste printed on the PCB board after solder paste printing and before component placement, including parameters such as solder paste quantity, printing position, shape, etc. By comparing with the preset standard values, defects in the solder paste printing process, such as uneven solder paste thickness, insufficient solder, excessive solder, solder paste offset, etc., can be discovered in time, thereby ensuring the quality of subsequent welding and improving production efficiency and product reliability.

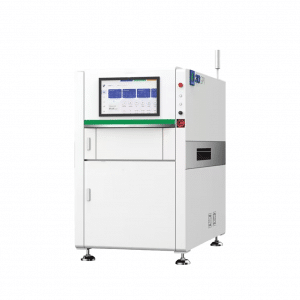

Showing all 2 results