Fully Automatic SMT Line setup – Pick and place machine cost analysis

QM61 fully-auto production line

QM61 SMT pick and place machine is designed for mass production or R&D proofing purpose. It contains 6 heads,63 slots .speed of up to 12000 components per hour (CPH),

This include complete range of PCB/PCBA handling system, high precision fully-automatic Solder paste stencil printer, Solder paste mixer, Pick and place machine , Lead free reflow oven , , SMT Reels storage Solution etc.

more details https://www.qhsmt.com/product/qm61-6heads-63slots-fully-automatic-pick-and-place-machine-smt-assembly-chip-mounter/

-1.png)

-

QH3502 Automatic Solder Paste Mixer

Read more -

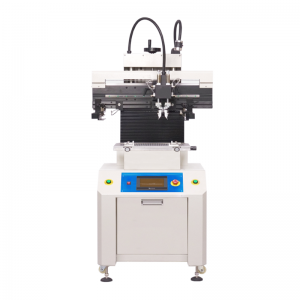

QP3250 Semi Automatic Stencil Printing 0.5meter

Read more -

QUL350 pcb up loader machine For Smt Pcb Circuit Board

Read more -

QM61 SMT pick and place machine 6heads 63slots Fully Automatic Pick&place machine SMT Assembly chip mounter

Read more -

SMT Inspection Conveyor used for easing, inspection, testing PCBs

Read more -

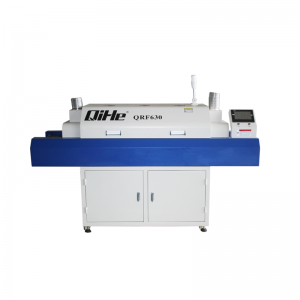

QRF630 6 Zones SMT Reflow Oven solder welding with cabinet

Read more

QM81 fully-auto production line

The QM81 SMT pick and place machine designed with 8heads 80slots ,speed of up to 16000 components per hour (CPH),

This include complete range of PCB/PCBA handling system, high precision fully-automatic Solder paste stencil printer, Solder paste mixer, Pick and place machine , Lead free reflow oven , , SMT Reels storage Solution etc.

more details https://www.qhsmt.com/product/qm81-8heads-80slots-fully-automatic-chip-mounter-smt-assembly/

-

QUL350 pcb up loader machine For Smt Pcb Circuit Board

Read more -

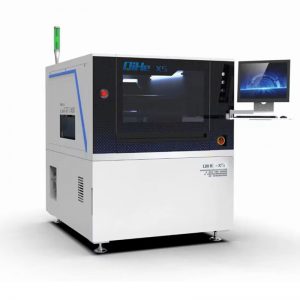

QP5060 automatic solder paste printer stencil printer machine screen printer machine

Read more -

Q8 SMT pick and place machine 8heads 80slots Fully Automatic Chip mounter SMT Assembly

Read more -

SMT Inspection Conveyor used for easing, inspection, testing PCBs

Read more -

RF8835LS up8/down8 Zones Reflow Oven solder welding

Read more -

QDL350 pcb un loader machine For Smt Pcb Circuit Board

Read more

QM10 fully-auto production line

The QM10 SMT pick and place machine designed with 10heads 80slots ,speed of up to 23000 components per hour (CPH).This include complete range of PCB/PCBA handling system, high precision fully-automatic Solder paste stencil printer, Solder paste inspection, Pick and place, Lead free reflow oven , automatic optical inspection (SPI,AOI) (from our partners), SMT Reels storage Solution etc.

more details https://www.qhsmt.com/product/pnp-machine-qm10-10heads-80slots-fully-automatic-chip-mounter-smt-assembly/

-

QUL350 pcb up loader machine For Smt Pcb Circuit Board

Read more -

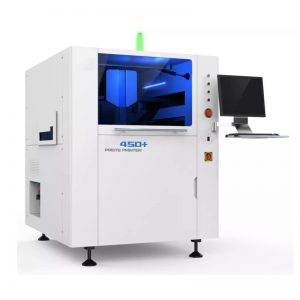

QP450+ automatic vision solder paste printer stencil printer machine screen printer machine

Read more -

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

Read more -

SMT Inspection Conveyor used for easing, inspection, testing PCBs

Read more -

QRF1235 12 Zones SMT Reflow Oven solder welding with guide rail

Read more -

QDL350 pcb un loader machine For Smt Pcb Circuit Board

Read more

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

WHAT IS SMT MACHINE?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, connecting table, etc. For these SMT assembly line equipment, Qihe smt can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.

WHAT IS SMT PROCESS?

There are mainly three steps in SMT assembly line process flow: solder paste printing, components placement and reflow soldering.

1. Solder Paste Printing

Its function in SMT line process is to print the solder-free paste on the pads of the PCB to prepare for the soldering of the components. The equipment used is a screen printing machine, located at the forefront of the SMT production line.

2. Components Placement

Its function is to accurately install the surface mount components on the fixed position of the PCB. The equipment used is a placement machine, located behind the screen printing machine in the SMT production line.

3. Reflow Soldering

Its function in SMT manufacturing line is to melt the solder paste so that the surface mount components and the PCB board are firmly bonded together. The equipment used is a reflow oven, located behind the placement machine in the fully automatic SMT production line.

What is SMT used for ?

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including and other products.

Read more https://www.facebook.com/Qihesmt