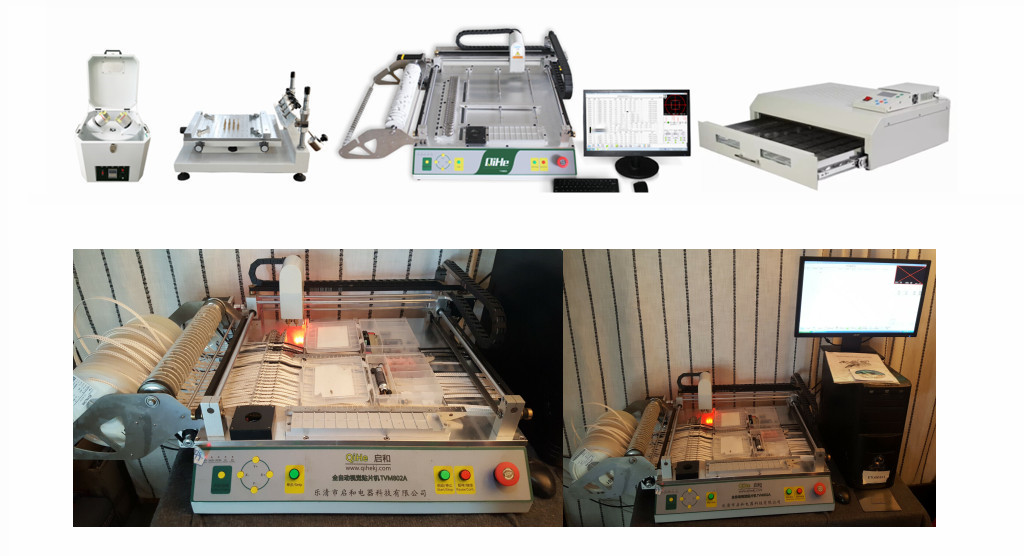

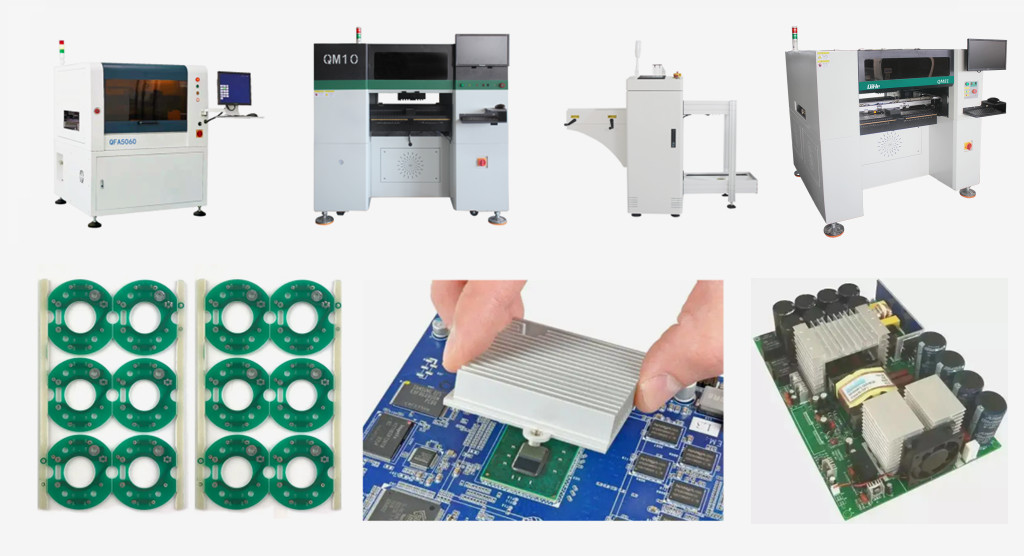

Qihe joined the electronic summit smartBHARAT 2022

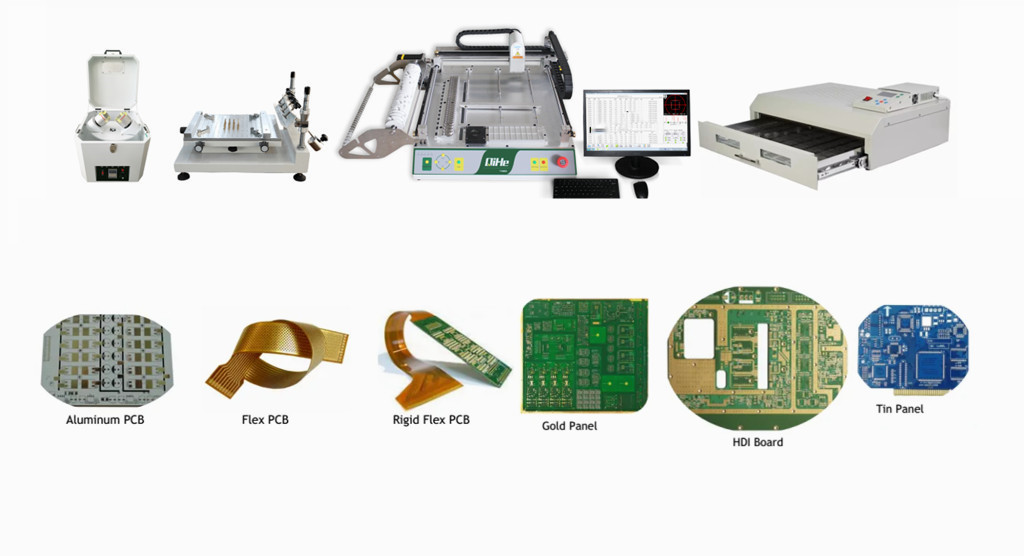

This week, Qihe joined a three-day summit : smartBHARAT 2022 | INDIA ELECTRONIC WEEK.We showed the popular models PNP smt pick and place machine QL41 4heads LED placement machine,TVM802AX desktop smt pick and place machine and reflow oven machine such as QRF320 ,etc.