Description

QL41 led pcb assembly machine SMT pick and place machine(pick&place machine) with four mounting heads can pick 4 materials and through vision at the same time.

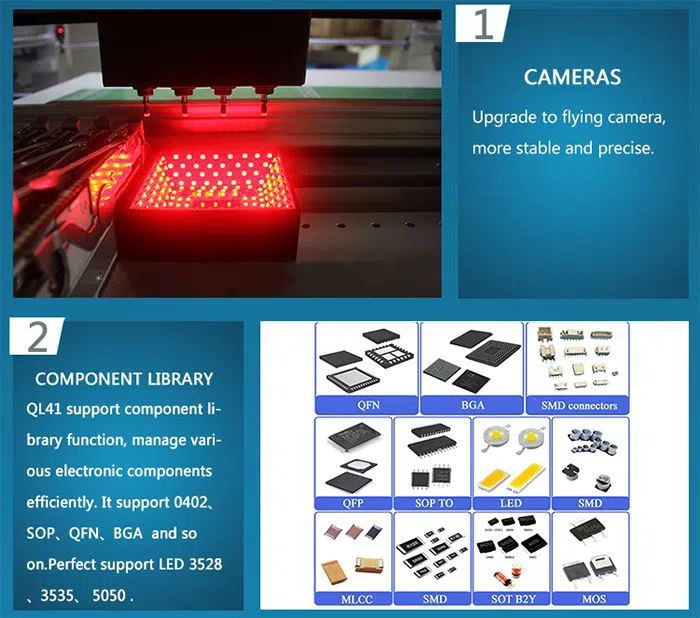

Flying vision components inspection camera is more stable, making mounting speed fast.

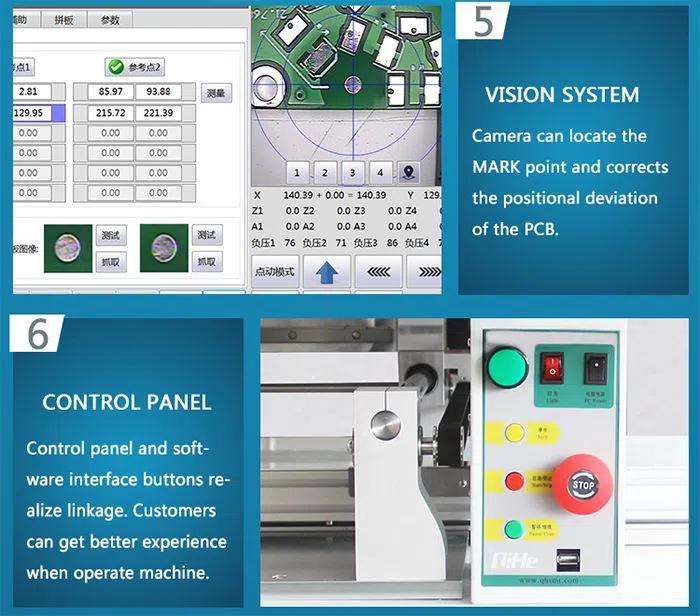

One PCB detection camera used to detect circuit board placement.

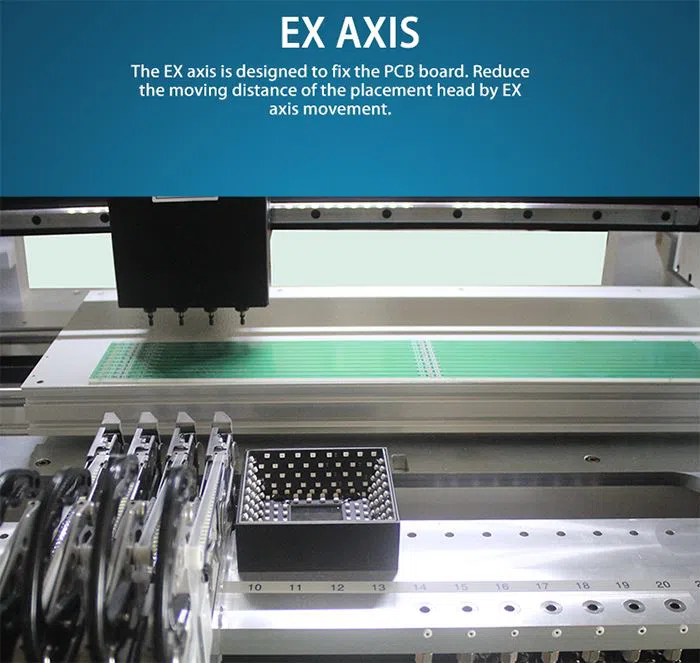

The EX-axis is designed to lay up the circuit board. In the process of mounting,

the ex axis moves, driving the circuit board to move, so that the shortest mount distance.

Mounting length up to 1200mm. Suitable for various types of LED strips and boards.

Closed-loop motors design, automatic detection and correction of lost step.

| Model | QL41 |

| Max applicable PCB | 1200*240mm |

| Max XY Moving rang | 530*430mm |

| Max Z Moving range | 15mm |

| Placement head quantity | 4 |

| Mounting speed | Vision off: 13000CPH Vision on: 10000CPH |

| Applicable component | SOP8.LED3535,5050 etc. |

| Component supply | Tape reel, Bulk, Tubular etc. |

| Vision system | Flight Camera |

| Control scheme | Closed-loop motor |

| Feeder count & Tape width | standard 8slots,customized16slots (8mm,12mm,16mm,24mm) |

| Power | 125W(average power) |

| Power supply | AC220V or AC110V |

| Machine size | L2060*W630*H660mm |

| Packing size | L1470*W780*H900mm |

| Volume | 1.02CBM |

| Net weight | 156kg |

| Gross weight | 210kgs |

| Support PCB design software | Protl99/Altium Designer/Eagle/Pads/Allegre etc. |