Description

| Mode | QH-800 |

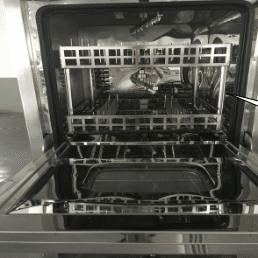

| Cleaning chamber size | L690 x W620 x H715(mm) |

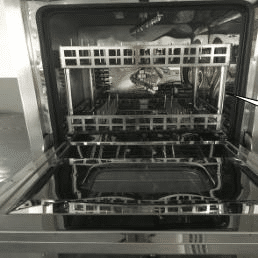

| Cleaning basket size | L610 x W560 x H100(mm),Double layer design |

| Concentrate tank capacity | 30L |

| Diluent tank capacity | 70L |

| Spray tank capacity | 17L-23L |

| Inner cavity temperature compensation power | 6KW |

| Solvent tank heater power | 9KW |

| Drying heater power | 6KW |

| Cleaning method | 360 degree rotary spray cleaning |

| Drying time | 5-20M(reference) |

| Rinsing time | 1-2 minutes / time |

| Rinse times | 1-10(can set as needed) |

| Drying time | 20-30M(reference) |

| Resistivity meter detection range | 0~18MΩ·cm |

| Dilution liquid heating temperature | (room temperature)~75℃ |

| Heating temperature of spray tank | (room temperature)~75℃ |

| Drying temperature | (room temperature)~99℃ |

| Chemical liquid recovery and filtration | 0.22μ m |

| DI water discharge and filtration | 0.22μ m |

| Intake | 1 inch fast junction interface |

| Drainage port | 1 inch fast junction interface |

| Diluent drain port | 1 inch fast junction interface |

| Horizontal spray pump | 5.5kw |

| Exhaust port size | Φ 100mm(W)×30mm(H) |

| Power supply/ Gas source | AC380V 50HZ 65A / 0.45Mpa~0.7Mpa |

| Machine net weight | 400Kg |

| Appearance size | L1200 × W1100 × H1830(mm) |

Feature of the equipment :

1.Comprehensive cleaning system:

Thorough and effective cleaning of organic and inorganic substances on the surface of the product.

2.Fully automatic cleaning mode:

Finish all the process of cleaning, rinsing and drying within a cleaning chamber, small size and compact structure.

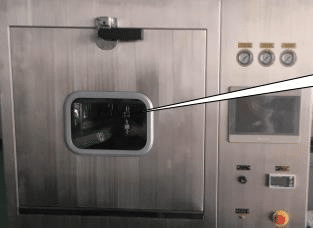

3.Visualization of whole process:

Spray room has visualization window, and equipped with LED lighting, cleaning process is clear at a glance.

4.Super Cleaning Capacity:

610mm(L)*560mm(W)*100mm(H). Double layer design, meet larger product sizes and higher cleaning capacities

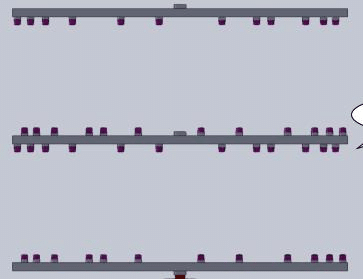

5.The most scientific nozzle design:

Use left and right incremental distribution to increase cleaning efficiency, upper and lower dislocation distribution to resolves Cleaning Blind Zone thoroughly.

6.Adjustable nozzle pressure design:

Reduces the hidden danger of collision and splash caused by high-pressure spray conditions in small-size products during cleaning.

7.Standard dilution tank heating system:

Greatly improved cleaning efficiency and reduced cleaning time.

8.Large touch screen operation interface:

Stable and reliable color touch screen, can set difference cleaning process according to difference product. simpler operation.

9.High standard of cleanliness:

The degree of ionic contamination is fully in line with IPC-610D’s Class III standard(less than 1.56μ g/ c ㎡ ) and the I standard of the US military standard 28809.

10.Convenient Cleaning Agent Proportion:

Can manual addition, can automatically mix DI water and chemical liquid according to the set ratio (5%-25%)also.

11.Concentrate and diluent added:

Separate liquid addition system makes liquid addition easier, faster, saves time and labor.