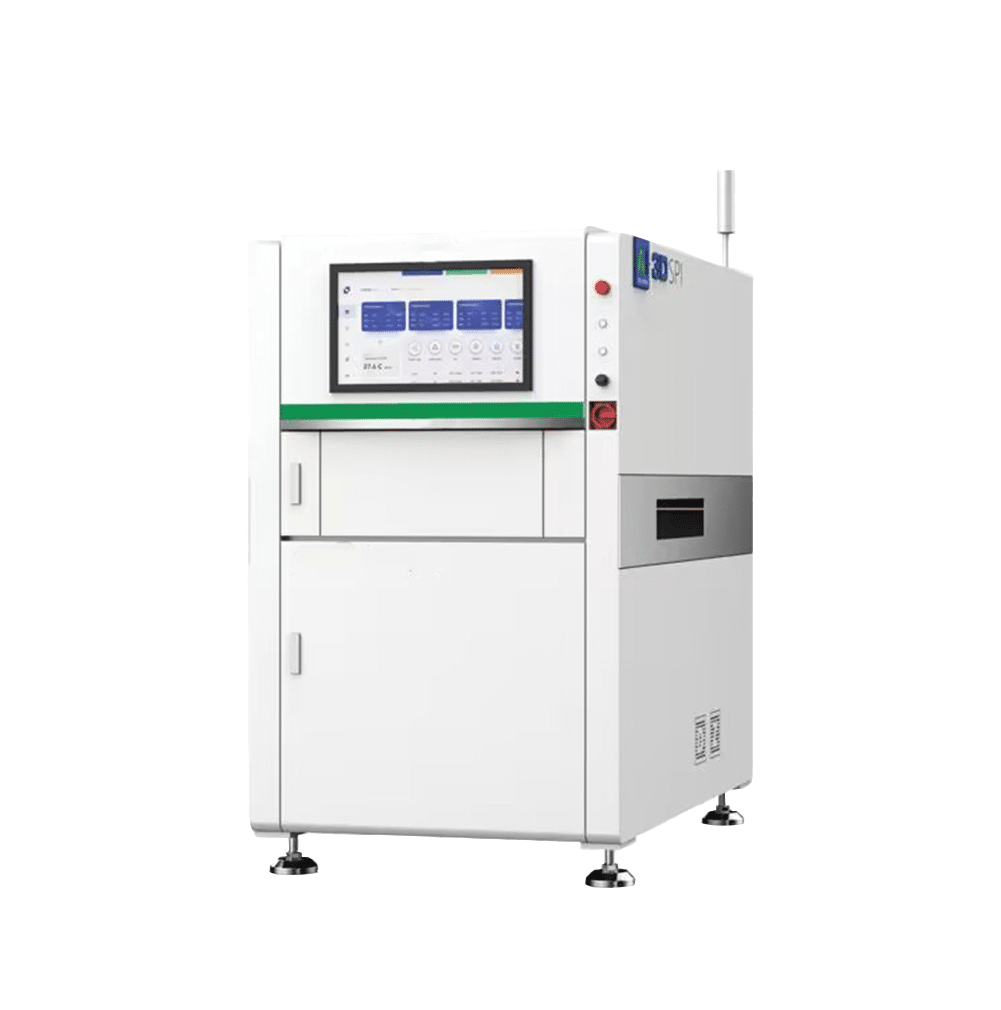

Description

The single-track 3D SPI is used in SMT for quality inspection after solder paste printing. It uses 3D imaging technology to perform high-precision inspection of solder paste on PCB boards, obtain key parameters such as volume, height, shape, and offset of solder paste, and compare the inspection data with standard data to promptly detect defects in solder paste printing, such as insufficient solder, excessive solder, short circuit, offset, etc. This helps to screen out defective products before subsequent processes, reduce welding defects, improve production efficiency and product quality, and provide data support for process optimization.

| Model | QS400 | |

| Vision system | Imaging | 1200W, 2100W(Optional) |

| Resolution | 5μm/10μm/15μm/20μm | |

| FOV size | 20mm*15mm/40mm*30mm/60mm*45mm | |

| Speed | 0.3s/FOV | |

| Lens Types | Telecentric lens | |

| Projector | 2 projector | |

| Motion mechanism | Accuracy | Ball screws accuracy:±1μm, Position accuracy:±10μm |

| XY axle control | AC Servo motor | |

| Z axis real time lifting plate bending compensation | Standard configuration | |

| Flow to | Left to right; right to left; left to left, right to right ( optional) | |

| Track height | 900±30mm | |

| Optional function | Substrate size | 400*400mm |

| Inspection items | Height, area, volume, offset, shape | |

| Non-Perform Types | Missing, shift, insufficient tin, excessive, bridge, offset, mal-shapes, particle | |

| Repeatability | Repeatability | 4 Sigma: height<1μm, volume<1%; area<1% |

| Gage R&R | <10% | |

| Software | Data statistic | Histogram;Xbar-R chart, Xbar-s Chart; CP&CPK,GR R, SPI Daily/weekly/Monthly report, MES(Optional) |

| Auxiliary function | Remote repair, Barcode reading | |

| Gerber and CAD | Support Gerber (274X,274D), CAD | |

| Equipment information | Power Supply | AC220V,3KW |

| Pressure | 0.4-0.6MPa, 5L/min | |

| Size/Weight | 1000*1640*1670mm, 800KG | |

| Port type | Standard SMEMA interface | |

| Option function | Artificial intelligence | AI Data Training Center |

| Auxiliary function | Remote centralized review, Barcode reading, OCR recognition | |

| Computer configuration | Type of computer | High performance industrial computer |

| CPU | Intel 12 | |

| Memory & GPU | 64G;8G | |

| Hard drive capacity | SSD500G+2T | |

| Display | 22”LCD | |

| Operating system | Win10 Enterprise Edition |

About QIHE SMT pick and place machine

QHSMT is an enterprise specializing in the production of SMT equipment, like pick and place machine ,reflow oven,stencil printer ,smt pick and place machine,pnp,pick&place,pcb assembly,smd chip shooter,pnp machine,chip mounter,smt line,welcome to send inquiry

you can choose a reflow oven to meets your need like qfr630,qrf835,qrf1235

stencil printer model qh3040,qp3250,qfa5060

Also we have different kinds of smt pick and place machine like tvm802a,tvm802b,tvm802ax,tvm802bx,tvm802b plus,tvm925s,tvm926s,ql41,qm61,qm62,qm81,qm10

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, conveyor,connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.