Description

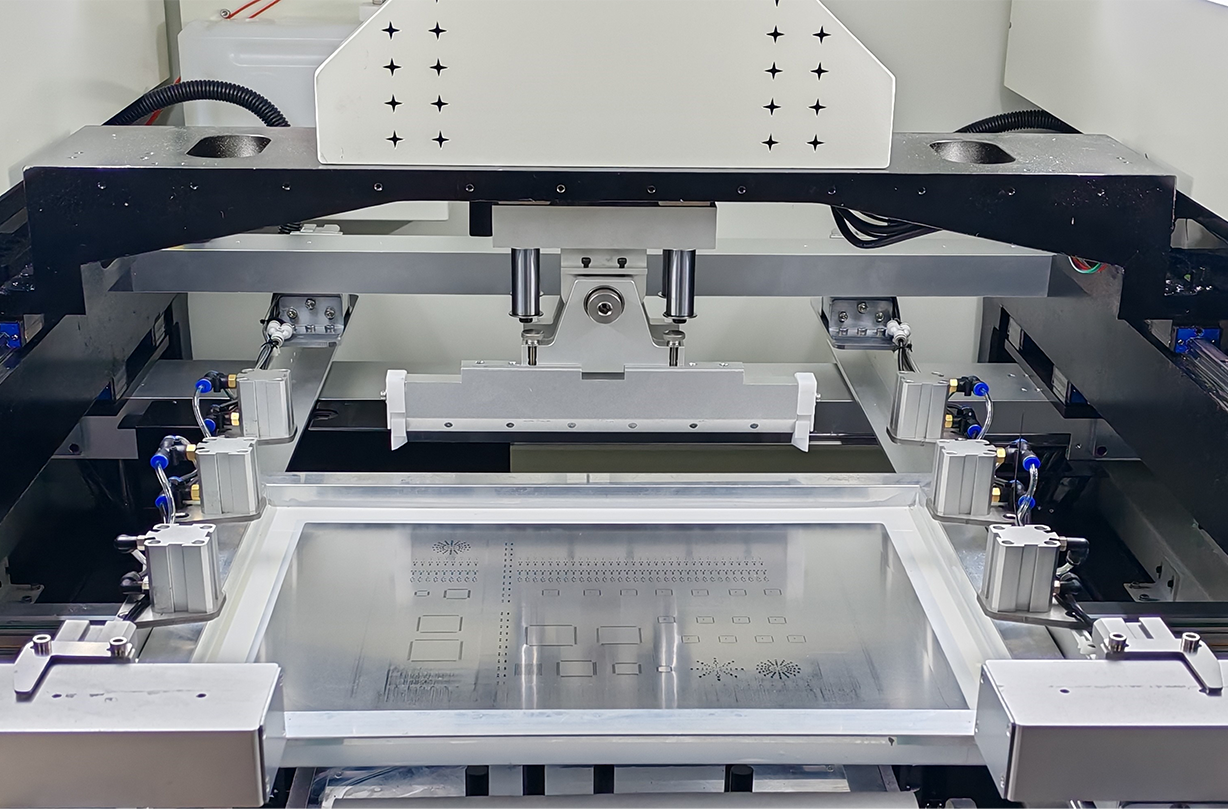

Stencil Positioning System

Humanized steel mesh positioning system,it is applicable for stencils of various size.Automatic stencil positioning system saves the line changeover time and enhances the overall efficiency.

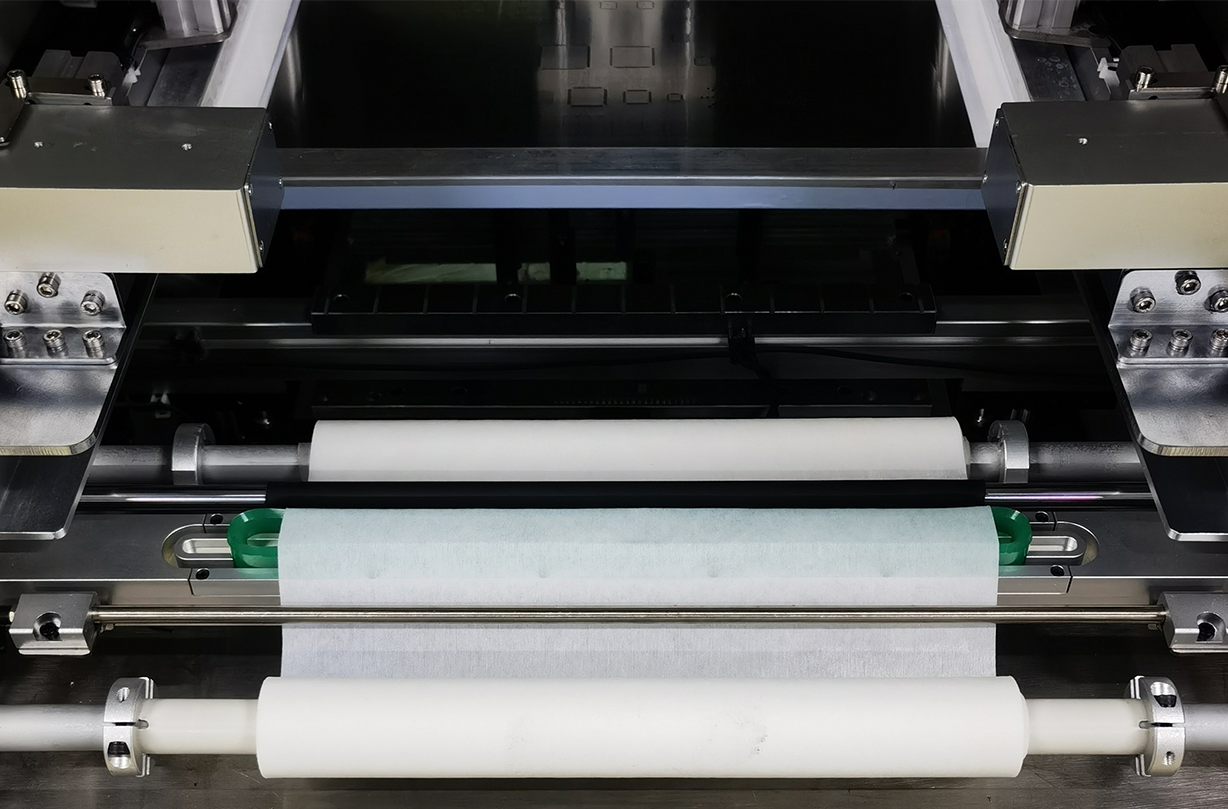

Cleaning System

The Installed on the front stencil cleaning system have 3 options: Dry cleaning, Wet cleaning and Vacuum cleaning can be selected to use,both individually and multiply.And you can also choose to clean manually. The unit to clean is separated from CCD camera,which can minimize the load of motor and impulse,improve the positioning precision and speed and extend the service life.The software function can control the dosage of alcohol and stencil cleaning paper,Effectively save more consumables.Vacuum cleaning is supported with a dedicated fan,powerful and effective.

Accurate optical positioning System

Uniform ring light,high brightness coaxial light and advanced upper/lower vision system Full range of light compensation,Automatic and accurate recognized of all type MARK points.Applicable for tin plating ,copper plating,gold plating,tin spraying,FPC and other types PCB.

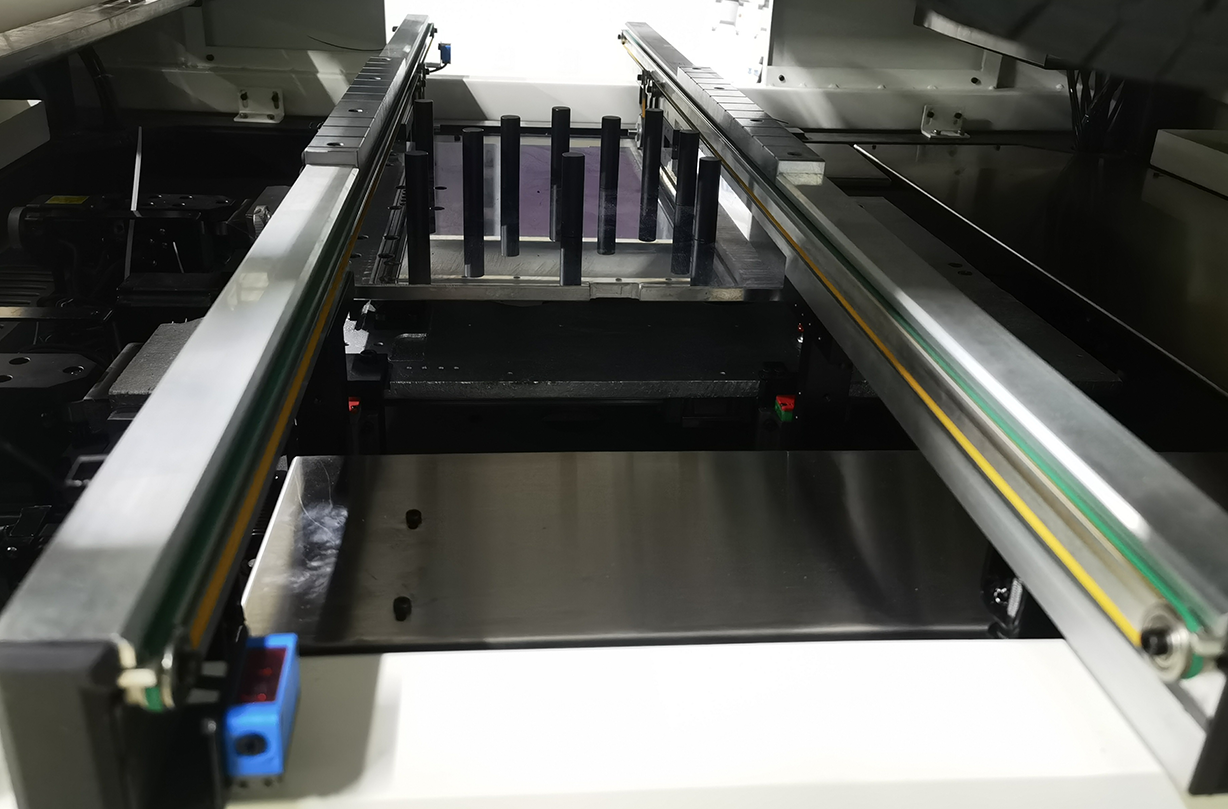

Special Platform Calibration System

U,V,W three axes linkage is designed with super-high dynamic characteristics and with classic and reliable structure,it can quickly adjust the offset of pcb。

Operation Interface

Using Windows win7 operation interface,and easy to leran for user,with good man-machine interactive function.Programing is designed with teaching and navigation function,guidance is available on every step.Chinese/English selectable Operating Joumal/Breakdown Record/Breakdown Diagnosis.

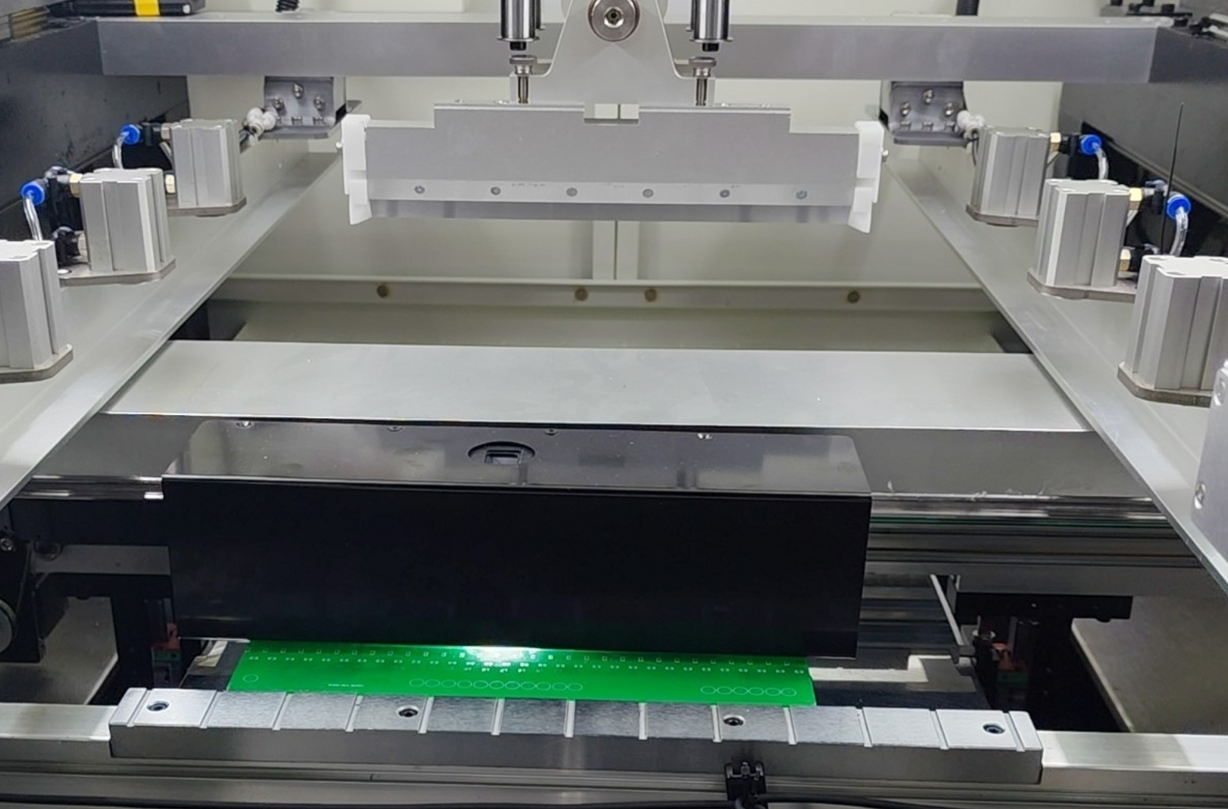

PCB Transport & Clamping System

Unique belt transmission system avoids being stuck or fall-off of PCB.Programmable motor controls transport speed and puts PCB in the precise position.Free to choose left of right as the PCB input/output direction.Flexible side clamp and PCB support vacuum block hold PCB tightly and ensure the full even contact between PCB and stencil.

| Model | RSE | |

| Frame size | MIN SIZE | 370*370mm |

| MAX SIZE | 737*737mm | |

| THICKNESS | 15-35mm | |

| Min PCB size | 50*50mm | |

| Max PCB size | 400*350mm | |

| PCB Board thickness | 0.4-9mm | |

| PCB War page | <1% | |

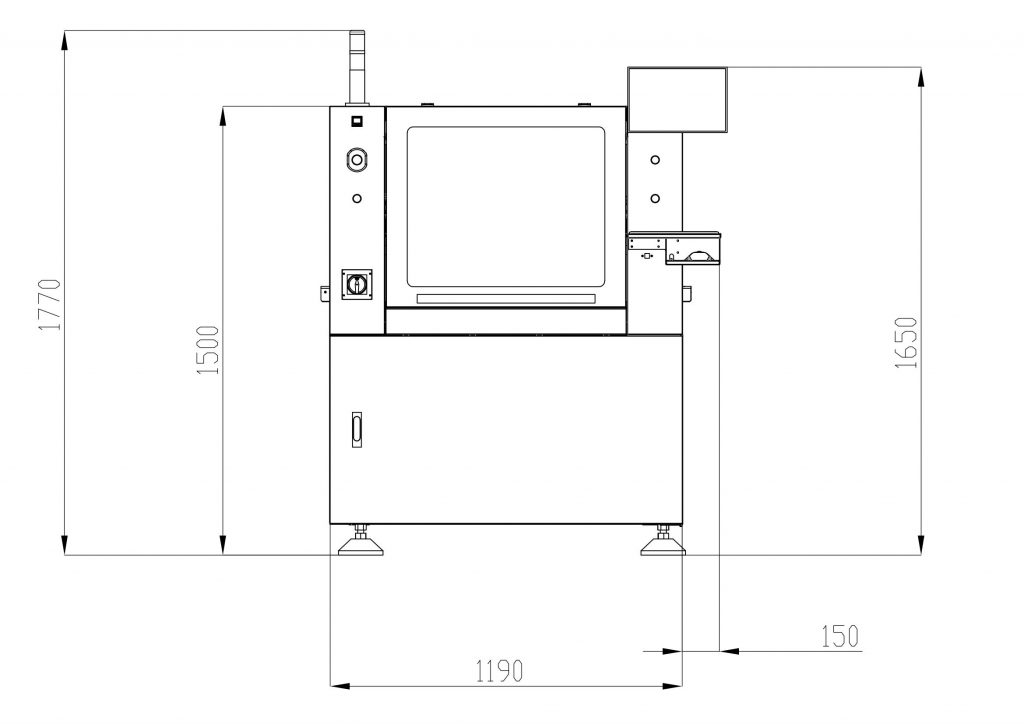

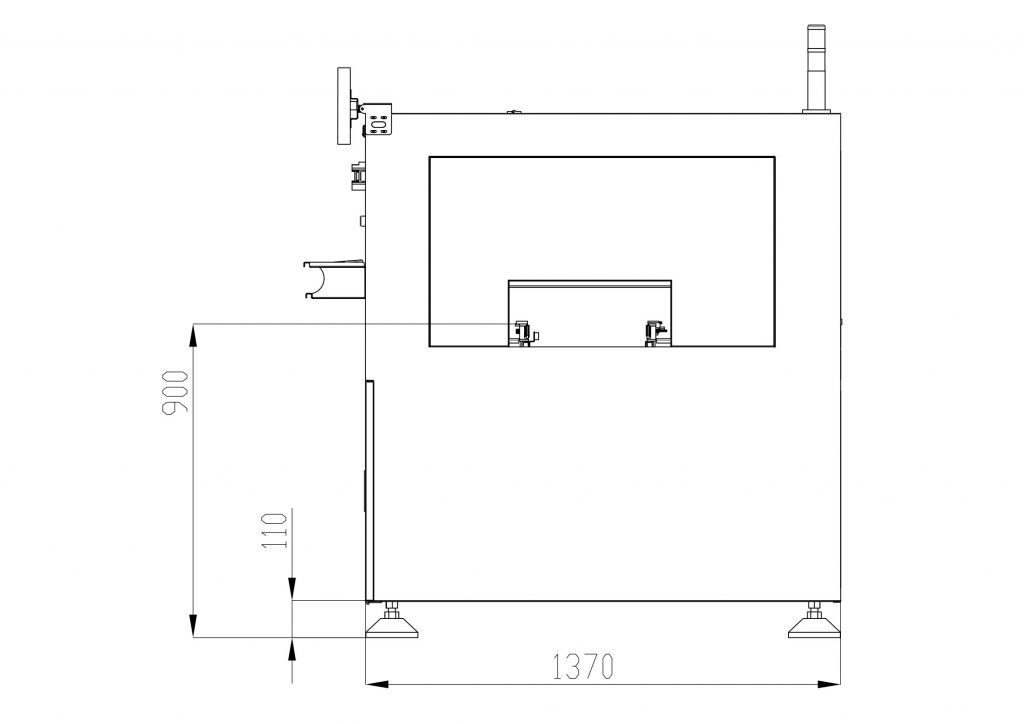

| Transport Height | 900 ± 40mm | |

| Transmission direction | Left-Right,Right-Left,Left-Left,Right-Right | |

| Transport speed | Max 1500mm/s(Max) ,Adjustable speed | |

| PCB Location | Support System | Magnetic Pin/Up-down table adjusted/Support block by hand |

| Clamping System | Side clamping | |

| Print Head | Two independent motorised print heads | |

| Squeegee Speed | 5-200mm/sec | |

| Squeegee Pressure | 0.5~10Kg ,motor control | |

| Squeegee Angle | 60° /55° /45°(matching the printing process) | |

| Squeegee Type | Stair less steel(Standard),plastic | |

| Stenail Separation Speed | 0.1-20mm/sec Programmable | |

| Clean System | Dry/wet/manual(Programmable) | |

| CCD FOV | 7 x 7mm | |

| Machine platform adjustment range | X=±3mm,Y=±7mm,θ=±2° | |

| Machine | ||

| Repeat Position Accuracy | ±0.02mm | |

| Printing Accuracy | ±0.03mm | |

| Cycle Time | <10s(Exclude Printing & Cleaning) | |

| Product Changeover | <5Min | |

| Air Required | 4.5-6Kg/cm² | |

| Power input | AC:220+10%,50/60HZ 1Ф 3KW | |

| Control Method | PC Control | |

| Machine Dimensions | 1190(L)*1370(W)*1500(H)mm | |

| Machine Weight | Approx: about 600Kg | |

What is SMT in engineering?

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,automatic solder paste printer and other products.

Small desktop pick and place machine TVM802A,TVM802B,TVM802AX,TVM802BX series suitable for beginners, for hobbiest or low vol usag.

Advanced level 4-head LED strip placement QL41 led machines and with rail universal series TVM925S,TVM926S,

Fully automatic 6-10-head placement QM61,QM62,QM81,QM10,machines, which are suitable for high volume mass production in factories.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/