In the application of DC/DC switching power supply, the external capacitor at the output load end can play a role in filtering and suppressing interference. In some equipment with dynamic jumps of large capacitive loads, the output end of the power supply is required to respond quickly, which requires The switching power supply has a strong ability to carry capacitive loads and has good stability. In the design process of switching power supply, in order to fully understand and realize the special requirements of customer load use, it is necessary to analyze the two different state requirements of the capacitive load capacity of switching power supply.Today qihe smt pick and place machine sharing capacitive load of small DC switching power supply .

Capacitive load requirements

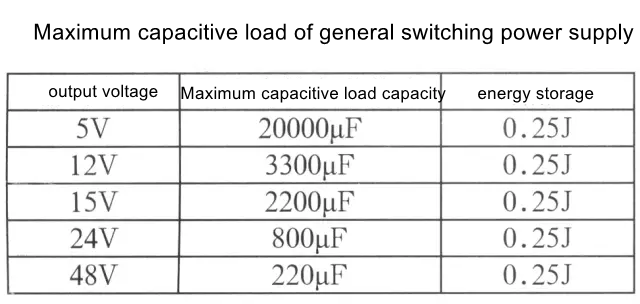

Among the basic characteristics of switching power supplies, there are generally no strict specifications for capacitive load capabilities. Generally, power supplies can carry quite capacitive loads, but considering the overcurrent protection capability of the power supply, especially the output short-circuit protection, the capacitive load capability cannot be too large, otherwise the protection capability will become worse. For capacitive loads carried by modules with multiple outputs, the distribution principle is that the total energy stored in the capacitor cannot exceed 0.25J, including the sum of the capacitor stored energy in the main circuit and the stored energy in the auxiliary circuit (1/2∑CU2).

Based on this calculation, the selection of the maximum capacitive load in the design is as shown in Table 1 (the maximum capacitive load of modules with different circuits and output powers will be different, and you need to refer to the relevant given technical parameter manual for actual selection and use) In actual design and application, the output capacitive load capacity of the switching power supply is debugged and tested by the following two requirements:

1) The power supply works stably, only the load jumps from no load to full load, and the output voltage is stable.

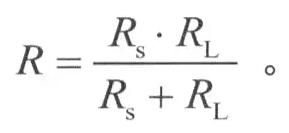

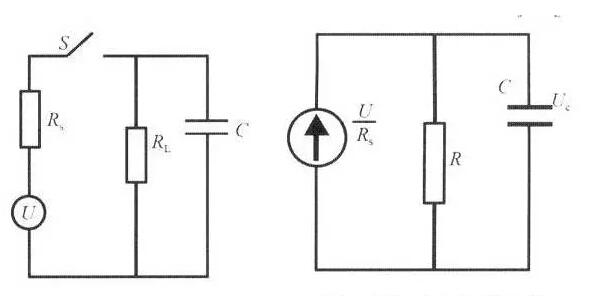

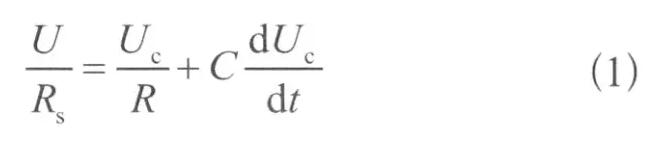

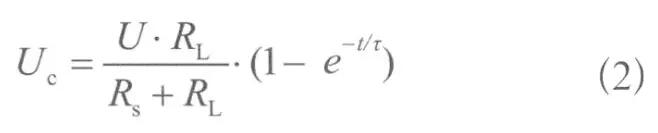

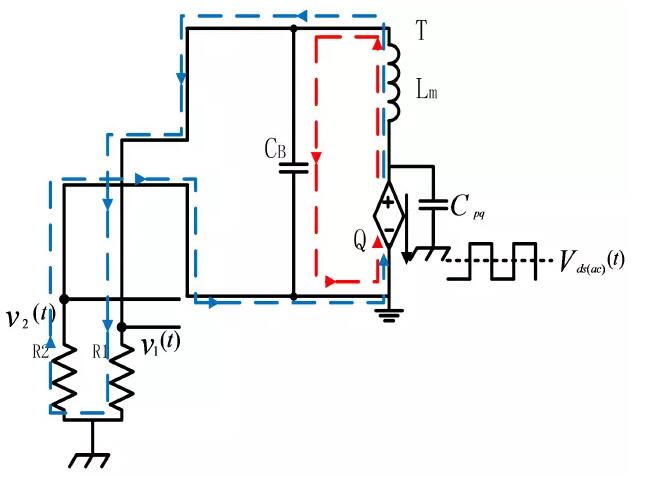

When the module is working normally, the DC/DC switching power supply can be equivalent to a voltage source, and its output equivalent circuit diagram and simplified equivalent circuit diagram are shown in Figure 1 and Figure 2 respectively. Among them, U is the output voltage, RS is the equivalent internal resistance, RL is the output load resistance,

C is the output capacitor,

Figure 1 is the output equivalent circuit diagram

Figure 2 is a simplified equivalent circuit

According to Figure 2,

It can be considered that the capacitor voltage UC is zero before the switch S is closed, and it can be obtained from equation (1)

From the above calculation, it can be seen that the capacitor voltage VC is rising exponentially. To establish the output voltage faster and more stably, the power supply output internal resistance must be small. Generally, a high-gain, fast-responding output voltage stabilizing feedback loop is used. Improvements and enhancements in performance can be achieved.

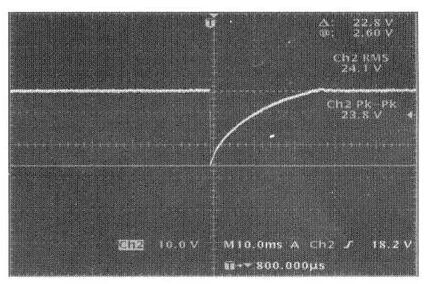

However, due to the energy storage of the output inductor, voltage feedback and front-end peak current control, the capacitor voltage is not entirely an exponential waveform rising from zero, as shown in Figure 3.

Figure 3 Output voltage waveform when capacitive load jumps

During the stabilization process of the output voltage, on the one hand, it is gradually supplemented by the energy storage of the output filter inductor; on the other hand, the primary side of the feedback loop control circuit quickly outputs greater power. The value of the output inductor is generally determined by the current ripple coefficient λ and the no-load characteristics of the power supply. In order to avoid excessive undershoot of the capacitive jump output voltage and make the control circuit reach its limit, the value of the inductor must be greater than the theoretical value of λ. value calculated.

But at the same time, the voltage surge amplitude when the output is unloaded must also be considered, so the output inductor should not be too large. Large inductors are generally difficult to make and cost high, so the actual value of the inductor can be obtained experimentally. Figure 4 shows the jump waveform of the output inductor current and the maximum capacitive load capacity when the capacitive load changes suddenly when the output inductor Lout takes different values.

It is concluded from experiments that a module with a large output inductance has a large capacitive load. The inductor energy storage contributes to the stability of the output voltage. The current limiting protection circuit has a short working time, but the response time will be correspondingly longer.

2) The module starts with an output capacitor and the output voltage is stable

When the module is started with a large capacitor, the capacitor needs to be charged quickly to maintain the stability of the output voltage. A large current will be generated at the moment of startup. If the large current continues for too long during the startup process, the protection function of the module control chip will reach its limit, and poor startup will occur, that is, the output voltage cannot be established normally;

In addition, the size of the capacitive load directly affects the rise time of the output voltage, and application failures may occur in environments with strict output voltage rise time requirements.

Generally, the output voltage of a self-feeding power supply is directly proportional to the supply voltage. Before the output reaches the normal voltage, the chip VCC cannot meet the power supply requirements. Therefore, the power supply method of the startup circuit and the energy storage of the VCC capacitor are also important factors that determine the capacitive load capacity.

Methods to improve the capacitive load capacity of switching power supply

If the auxiliary power supply is an independent power supply, the soft start method can be used to slowly build up the output voltage. For self-fed power supply, if the soft start time is long, it will be difficult to start. In this case, the VCC capacitor capacity must be increased. The large capacity of VCC will have an impact on modules that rely solely on the internal current loop of the chip for short-circuit protection. Therefore, a balance point must be found between capacitive load and overcurrent (and short-circuit protection).

Appropriately reducing the value of the current limiting resistor is equivalent to increasing the output power of the power supply, which is used to increase the energy provided to the output load during the startup process. Adjusting the feedback loop parameters to speed up the desaturation of integrated components such as op amps and optocouplers can solve the serious problem of OVERSHOOT when capacitive loads jump, that is, improving the stability of the power supply.

Application and summary of capacitive load capacity

The demand for capacitive load is closely related to the application environment. Capacitive load capability is based on a balanced selection between short-circuit performance and overload protection capability. In the design of modules with special specifications, the above parameters must be optimized and debugged to achieve optimal design to meet specific application requirements Smt pick and place machine.,Smt pick and place machine,smt machine,smd machine,SMT equipment,pick and place machine,reflow oven,stencil printer,pnp,smt550 pick and place machine,QM61,QM62,QM81,QM10,Ball lamp bead pick and place,led pnp machine,smt pick and place machine,pick and place machines,pcb handling,led smt machine,used pick and place machine,smt line equipment,qihe,smt machine cost,how pick and place machine works,desktop smt pick and place machine,pick and place machine diy,pnp machine,smt line cost,desktop pick and place machine,home pick and place machine,diy pcb assembly,smt spare parts,led pick and place machine,diy pick and place machine,benchtop pick and place machine,semi automatic stencil printer,solder paste printer,smt conveyor,led machine,pcb assembly machine,smt pick place machine,electronic products machinery,pcb pick and place machine,smt machine price,automatic smt production line,small smt production line,machine pick and place,led pick and place machine,pcb manufacturing machine,led bulb assembly line,smd place machine,small smd production line,,small led production line,smt pick and place line,0201 pick and place,

Read more: Discuss on capacitive load of small DC switching power supplyBest seller SMT Machine :Qihe smt line products

-

SMT semi-automatic pick and place machine with Dispenser

-

TVM925 SMT pick and place machine 4 head 38 feeders slots assembly of electronic components

-

Q10 SMT Automatic pick and place machine 10 Heads 100 Slots High Precision and High Efficiency SMT/LED Assembly

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802BX SMT pick and place machine 2heads 46slots desktop pnp mounter deluxe edition

-

QL41 SMT pick and place machine 4heads 8slots LED for 1.2meters led strip pick&place machine

What is SMT in engineering?

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,and other Smt pick and place machine products.

Small desktop pick and place machine TVM802A,TVM802B,TVM802AX,TVM802BX series suitable for beginners, for hobbiest or low vol usag.

Advanced level 4-head LED strip placement QL41 led machines and with rail universal series Q4,TVM925S,TVM926S,pick and place

Fully automatic 6-10-head placement QM61,QM62,QM81,QM10,machines, which are suitable for high volume mass production in factories.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

What is SMT in programming?

Offline Automated Programming vs Inline SMT Programming

Qihe pick and place machine can be programmed directly on the SMT equipment .

Or Coordinates can also be imported csv file through programming software.

Currently supported software such as protel,DXP,Altium Designer,Pads,Candes,proteus,DXP.

Inline SMT programming is a solution to consider for narrow segments of device programming requiring short programming times, with medium to high volume, for just one device type Smt pick and place machine .

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, conveyor,connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.pick and place

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

https://www.qhsmt.com/fully-automatic-smt-pick-and-place-machine-line/