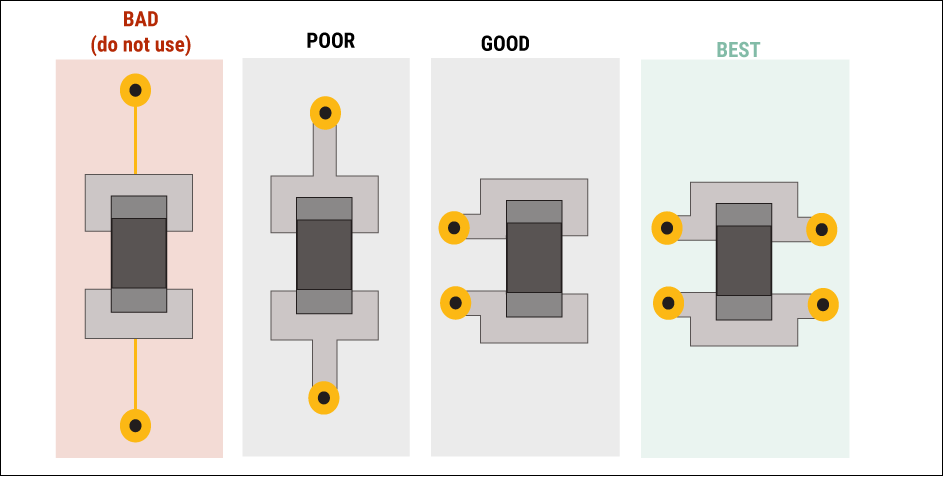

The decoupling radius is a measure of the effectiveness of a decoupling capacitor. It is a function of many factors, including the plane geometry, the frequency as well as the capacitor parameters.An important issue in capacitive decoupling is the decoupling radius of the capacitor. Most of the materials mention that capacitors should be placed as close as possible to the chip, and most of the materials talk about the placement distance from the perspective of reducing the loop inductance. Today qihe smt pick and place machine sharing Effective decoupling radius of decoupling capacitor. Indeed, reducing the inductance is an important reason, but there is another important reason that most materials do not mention, that is, the problem of capacitive decoupling radius. If the capacitor is placed too far away from the chip, exceeding its decoupling radius, the capacitor will lose its decoupling effect.

The best way to understand the decoupling radius is to examine the phase relationship between the noise source and the capacitive compensation current. When the chip’s demand for current changes, a voltage disturbance will be generated in a small local area of the power plane. To compensate this current (or voltage), the capacitor must first sense this voltage disturbance. It takes time for the signal to propagate through the medium, so there is a time delay between when a local voltage disturbance occurs and when the disturbance is sensed by the capacitor. Similarly, there is a delay for the compensation current of the capacitor to reach the disturbance region. Therefore, an inconsistency in phase between the noise source and the capacitance compensation current must be caused.

A particular capacitor works best at compensating noise at the same frequency as its self-resonance, the frequency at which we measure this phase relationship. In practical applications, this distance is best controlled at (1/40-1/50) wavelength, which is an empirical value.

For example: 0.001uF ceramic capacitor, if the total parasitic inductance after installation on the circuit board is 1.6nH, then the resonant frequency after installation is 125.8MHz, and the resonant period is 7.95ps. Assuming that the propagation speed of the signal on the circuit board is 166ps/inch, the wavelength is 47.9 inches. The capacitive decoupling radius is 47.9/50=0.958 inches, which is approximately equal to 2.4 cm.

The capacitor in this example can only compensate for power supply noise within a range of 2.4 cm around it, that is, its decoupling radius is 2.4 cm. Different capacitors have different resonant frequencies and decoupling radii. For large capacitors, because their resonant frequency is very low, the corresponding wavelength is very long, so the decoupling radius is large, which is why we don’t pay much attention to the placement of large capacitors on the circuit board. For small capacitors, because the decoupling radius is very small, they should be placed as close as possible to the chip that needs to be decoupled. This is what is repeatedly emphasized in most materials, and small capacitors should be placed as close as possible to the chip.

Read more: Effective decoupling radius of decoupling capacitorBest seller SMT Machine :Qihe smt line products

-

Q10 SMT Automatic pick and place machine 10 Heads 100 Slots High Precision and High Efficiency SMT/LED Assembly

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802BX SMT pick and place machine 2heads 46slots desktop pnp mounter deluxe edition

-

QL41 SMT pick and place machine 4heads 8slots LED for 1.2meters led strip pick&place machine

-

Q8 SMT pick and place machine 8heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802AX SMT pick and place machine 2heads 29slots desktop deluxe edition SMT Pick&Place Machine

What is SMT in engineering?

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,and other products.

Small desktop pick and place machine TVM802A,TVM802B,TVM802AX,TVM802BX series suitable for beginners, for hobbiest or low vol usag.

Advanced level 4-head LED strip placement QL41 led machines and with rail universal series TVM925S,TVM926S,

Fully automatic 6-10-head placement QM61,QM62,QM81,QM10,machines, which are suitable for high volume mass production in factories.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

What is SMT in programming?

Offline Automated Programming vs Inline SMT Programming

Qihe pick and place machine can be programmed directly on the SMT equipment .

Or Coordinates can also be imported csv file through programming software.

Currently supported software such as protel,DXP,Altium Designer,Pads,Candes,proteus,DXP.

Inline SMT programming is a solution to consider for narrow segments of device programming requiring short programming times, with medium to high volume, for just one device type.

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, conveyor,connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

https://www.qhsmt.com/fully-automatic-smt-pick-and-place-machine-line/