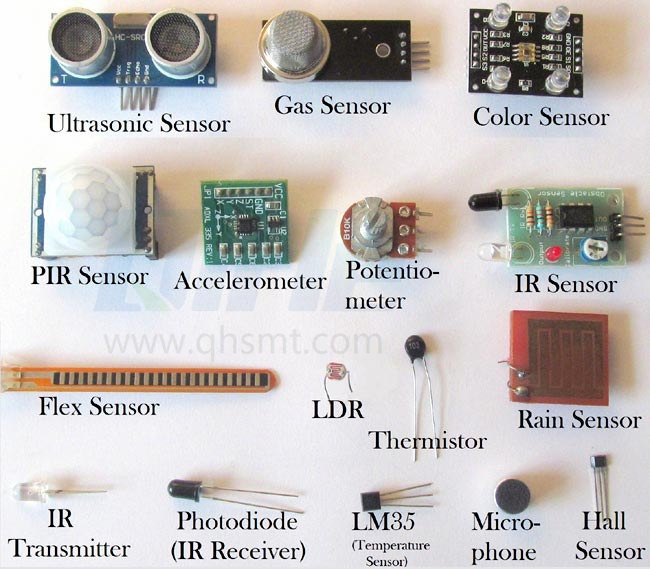

The production of smart home products is inseparable from sensors. As the sensing components of smart home, without them, there is no way to trigger smart scenes. For example, functions such as lights on when people come, door and window changes, indoor temperature and humidity self-regulation, and rain closing windows

When people design other different products, they will definitely use various sensors. Similarly, even when we design the smt machine like smt pick and place machine,reflow oven,pcb printer, smd loader we also use sensors with various types with functions to realize various functions and limits.

Modern sensors vary greatly in principle and structure. How to choose sensors reasonably according to the specific measurement purpose, measurement object and measurement environment is the first problem to be solved when measuring a certain quantity.

When the sensor is determined, the corresponding measurement method and measurement equipment can also be determined. The success or failure of the measurement results depends to a large extent on whether the selection of sensors is reasonable.

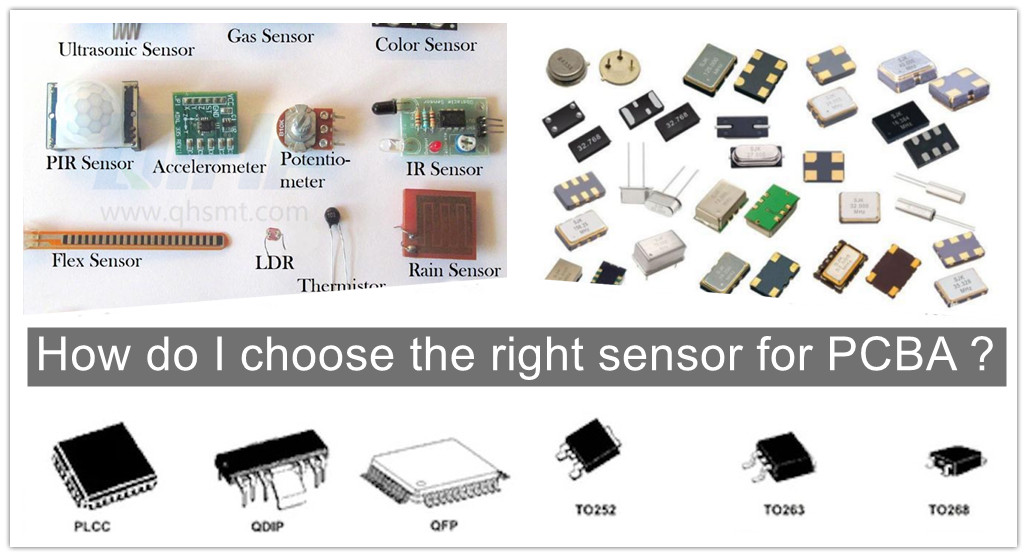

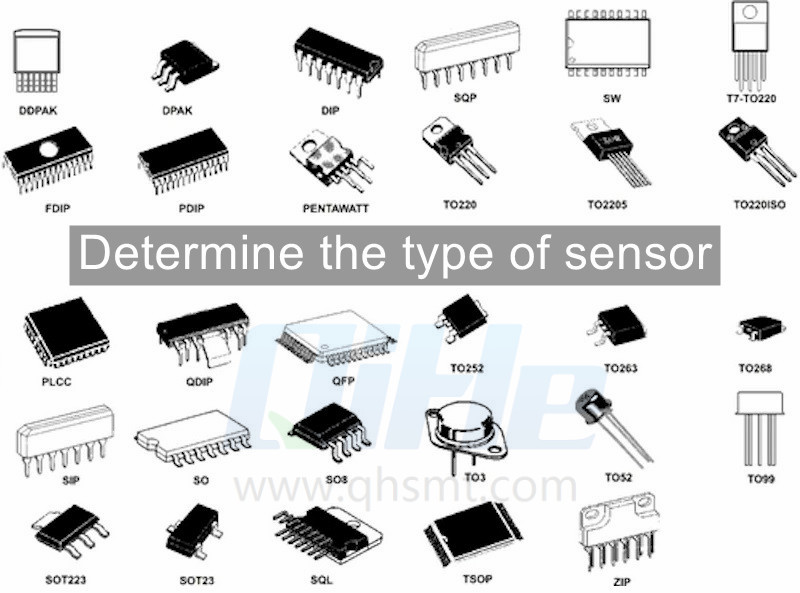

Determine the type of sensor

Determine the type of sensor according to the measurement object and the measurement environment. To carry out a specific measurement work, you must first consider what kind of sensor should be used, which needs to be determined after analyzing various factors.

Because, even to measure the same physical quantity, there are sensors with multiple principles to choose from. Which kind of sensor is more suitable, you need to consider the following specific issues according to the characteristics of the measured and the conditions of use of the sensor:

①The size of the measuring range;

②Requirements for the volume of the sensor at the measured position;

③ Whether the measurement method is contact or non-contact;

④ Signal extraction method, wired or non-contact measurement;

⑤ The source of the sensor, domestic or imported, whether the price is affordable, or self-developed. After considering the above problems, we can determine what type of sensor to choose, and then consider the specific performance indicators of the sensor.

Choice of Sensor Sensitivity

Generally, within the linear range of the sensor, it is desirable that the sensitivity of the sensor be as high as possible. Because only when the sensitivity is high, the value of the output signal corresponding to the measured change is relatively large, which is beneficial to signal processing. However, it should be noted that the sensitivity of the sensor is high, and the external noise that has nothing to do with the measured object is easy to mix in, and it will also be amplified by the amplification system, which will affect the measurement accuracy. Therefore, the sensor itself is required to have a high signal-to-noise ratio to minimize the interference signals introduced from the outside world.

The sensitivity of the sensor is directional. When the measured object is a single vector and requires high directionality, a sensor with low sensitivity in other directions should be selected; if the measured object is a multi-dimensional vector, the smaller the cross-sensitivity of the sensor is required, the better.

Sensor Frequency Response Characteristics

The frequency response characteristic of the sensor determines the frequency range to be measured, and it is necessary to maintain undistorted measurement conditions within the allowable frequency range. In fact, the response of the sensor always has a certain delay. It is hoped that the delay time should be as short as possible.

The frequency response of the sensor is high, and the frequency range of the measurable signal is wide. Due to the influence of the structural characteristics, the inertia of the mechanical system is relatively large, so the frequency of the measurable signal of the sensor with low frequency is low.

In dynamic measurement, the response characteristics should be based on the characteristics of the signal (steady state, transient, random, etc.) to avoid excessive errors.

Sensor linear range

The linear range of a sensor is the range over which the output is proportional to the input. In theory, within this range, the sensitivity remains constant. The wider the linear range of the sensor, the larger its range and can guarantee a certain measurement accuracy. When selecting a sensor, when the type of sensor is determined, the first thing to check is whether its range meets the requirements.

But in fact, any sensor cannot guarantee absolute linearity, and its linearity is also relative. When the required measurement accuracy is relatively low, within a certain range, the sensor with a small nonlinear error can be approximately regarded as linear, which will bring great convenience to the measurement.

Sensor Stability

The ability of a sensor to maintain its performance over time is called stability. In addition to the structure of the sensor itself, the factors affecting the long-term stability of the sensor are mainly the environment in which the sensor is used. Therefore, in order to make the sensor have good stability, the sensor must have strong environmental adaptability.

Before selecting a sensor, investigate its use environment, and select a suitable sensor according to the specific use environment, or take appropriate measures to reduce the impact of the environment.

There are quantitative indicators for the stability of the sensor. After the usage period is exceeded, it should be re-calibrated before use to determine whether the performance of the sensor has changed. In some occasions where the sensor is required to be used for a long time but cannot be easily replaced or calibrated, the stability requirements for the selected sensor are more stringent and must be able to withstand the test for a long time.

Sensor Accuracy

Accuracy is an important performance index of the sensor, and it is an important link related to the measurement accuracy of the entire measurement system. The higher the accuracy of the sensor, the more expensive it is. Therefore, the accuracy of the sensor only needs to meet the accuracy requirements of the entire measurement system, and it does not need to be selected too high. This makes it possible to select a cheaper and simpler sensor among many sensors that meet the same measurement purpose.

If the purpose of measurement is qualitative analysis, it is enough to use a sensor with high repeatability, and it is not suitable to use a sensor with high absolute value accuracy; if it is for quantitative analysis, it is necessary to obtain accurate measurement values, and it is necessary to select a sensor with an accuracy level that can meet the requirements.

For some special occasions, if the suitable sensor cannot be selected, it is necessary to design and manufacture the sensor by itself. The performance of self-made sensors should meet the requirements of use.

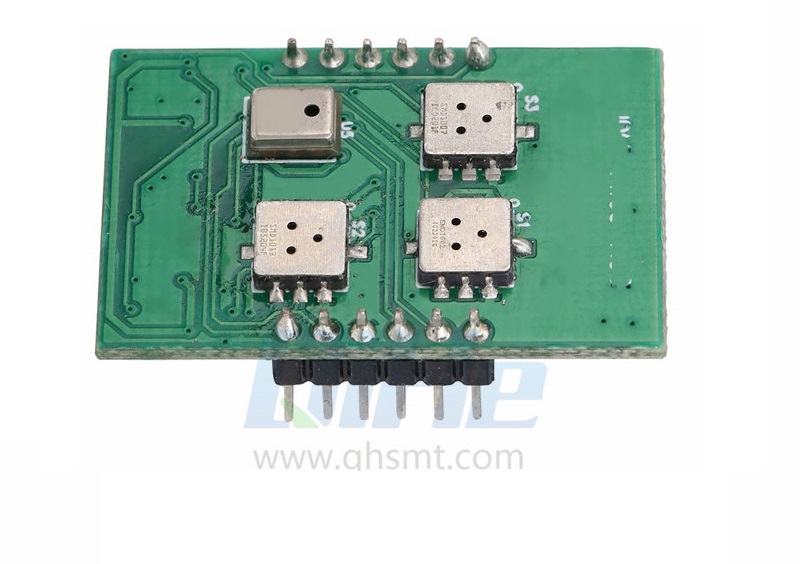

what is a smd sensor ?

Sensor (Sensor) is a common but very important device. It is a device or device that senses various quantities that are specified to be measured and converts them into useful signals according to certain rules. For sensors, according to the state of the input, the input can be divided into static quantity and dynamic quantity. We can obtain the static characteristics of the sensor according to the relationship between the output and input in the steady state of each value.

Best seller SMT Machine :Qihe smt line products

-

Q10 SMT Automatic pick and place machine 10 Heads 100 Slots High Precision and High Efficiency SMT/LED Assembly

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802BX SMT pick and place machine 2heads 46slots desktop pnp mounter deluxe edition

-

QL41 SMT pick and place machine 4heads 8slots LED for 1.2meters led strip pick&place machine

-

Q8 SMT pick and place machine 8heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802AX SMT pick and place machine 2heads 29slots desktop deluxe edition SMT Pick&Place Machine

About QIHE SMT pick and place machine

QiHe Electrical Technology Co.,LTD is a high-tech company,which located in Economic Development Zone, Yueqing,China. We professional designing and producing all kinds of , pick and place machine,reflow oven,stencil printer, We also providing SMT solutions .Our Products playing a leading role in SMT industry. We have set a long lasting cooperation and partnership with global customers .Warmly welcome you to visit our company for friendship and cooperation.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, conveyor,connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

QM81 smd pcb assembly