Recently, Qihe smt engineers received an invitation from a customer to visit the customer’s PCB assembly workshop.where a Qihe QM10 pick and place machine fully automatic production smt line setup.the SMT workshop including ,pcb uploader QUL350→fully-auto stencil printer QFA5060→SMT conveyor→10heads PNP machine QM10→PCB inspection conveyor→12 zone reflow oven with rail QRF1235→ pcb unloader QDL350.

After visiting the PCB assembly workshop, Qihe’s engineers visited the THT plug-in workshop. The main purpose of the plug-in workshop is to inspect and repair the semi-finished products shipped from the assembly workshop, because the fully automatic THT assembly and inspection machines are currently only built A line has been established, so manual inspection allows the product to achieve a higher pass rate! In the plug-in workshop, They watched the workers observe carefully under the magnifying glass, and they worked very attentively! A meaningful trip.

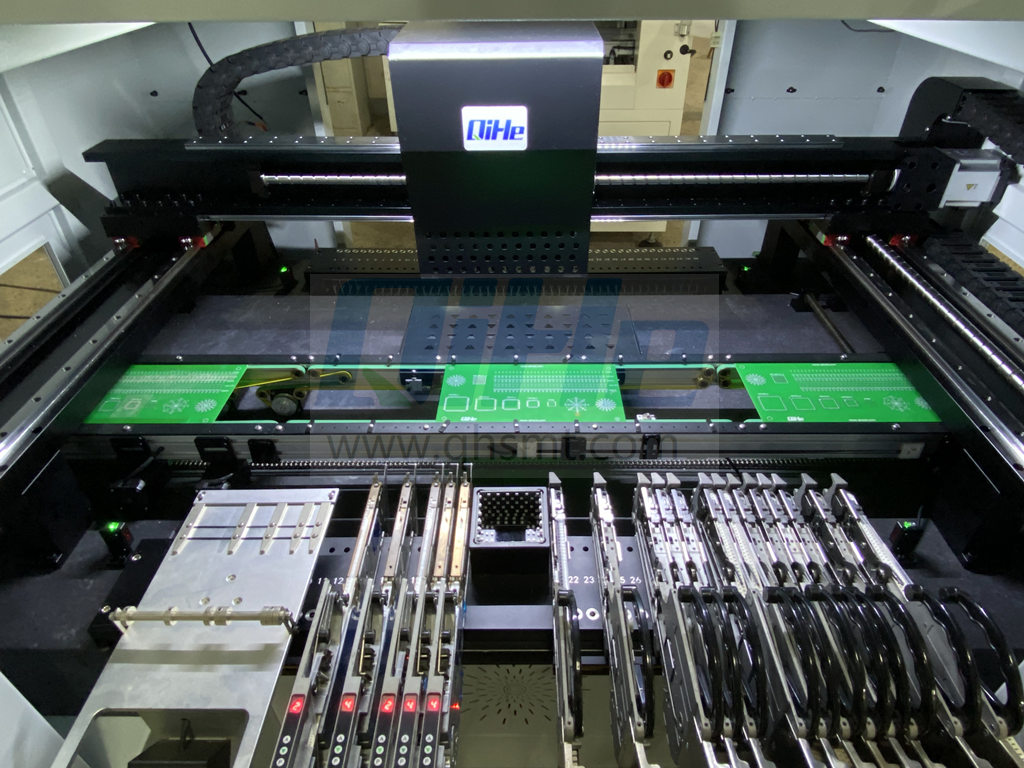

About QM10 SMT pick and place machine

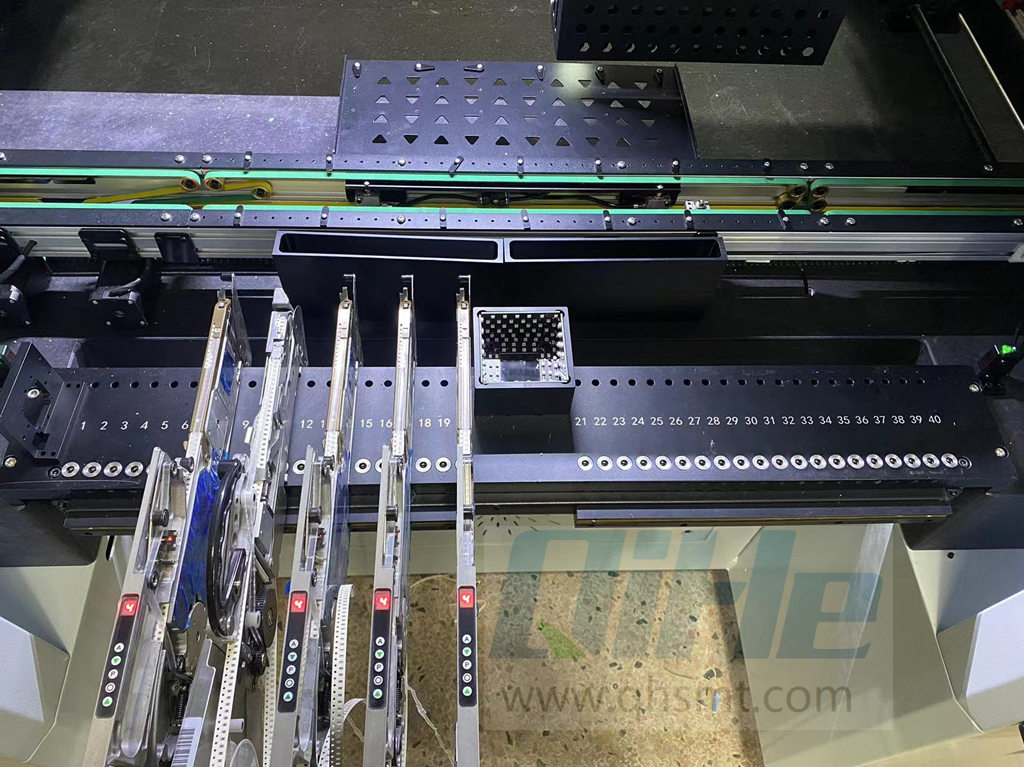

The QM10 SMT pick and place machine designed with 10 heads 86 slots ,QM10 pnp machine speed up to 23000 components per hour (CPH).

Upgraded the software functional such as the component library ,the visual surveillance,the safety alerts,the fault previously warning .

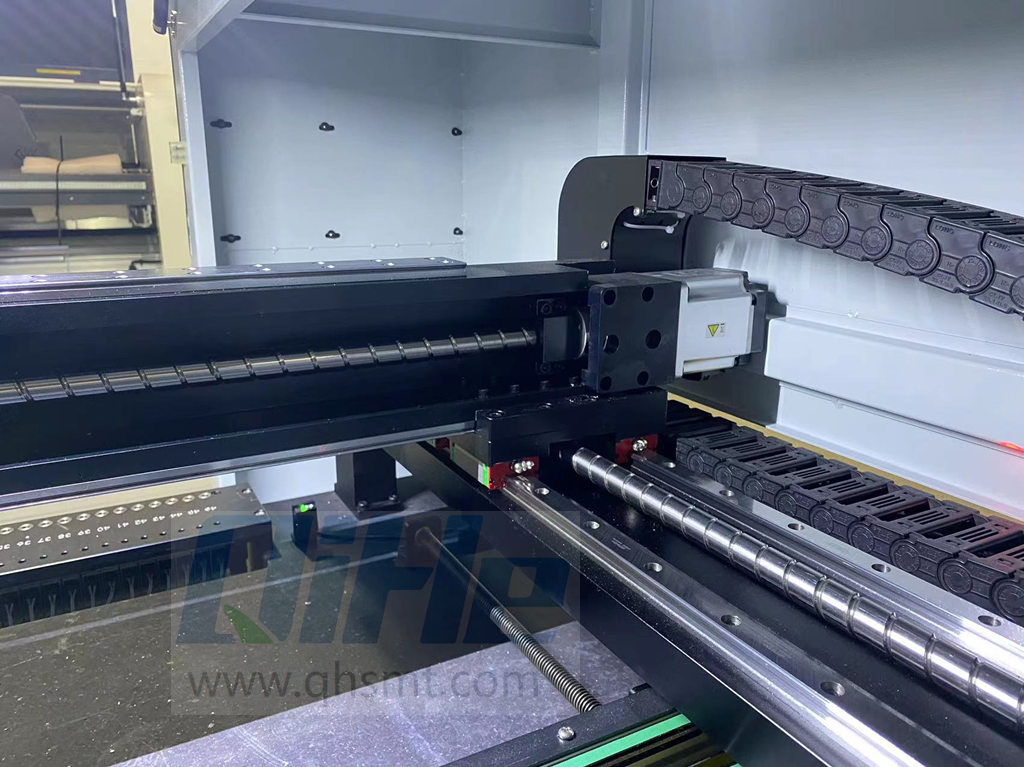

The model of Panasonic servo motor, driver, linear guide, and screw have been completely upgraded to cope with the working capacity of 10 heads .

Upgrades to Linear Guides

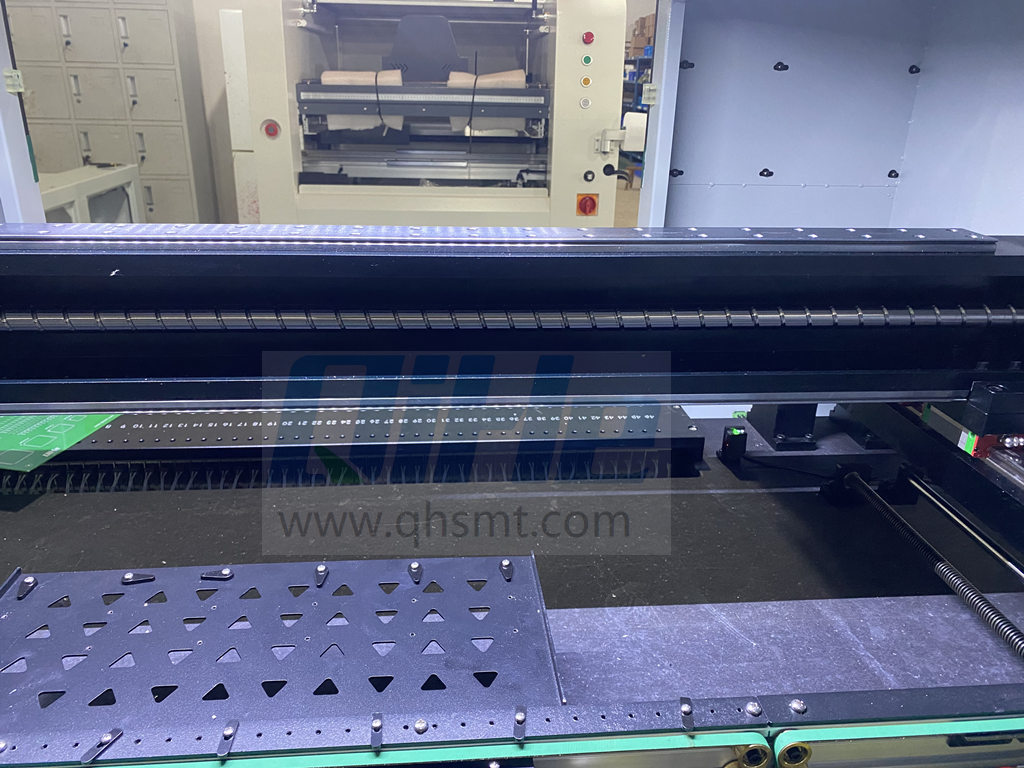

The X-axis improves the structure to increase the smoothness of operation .and increased the number of linear guides (top and bottom)

The Y-axis has also been increased into two linear guides on each side to improve accuracy and speed increase machine durable life.

Thickened marble base platform

The substrate iron plate inside the machine upgrade into thickened marble material to increase stability . Of course, in addition to the increase in weight, the stability of equipment operation has also been greatly improved. At the same time, you also need to consider the bearing weight of the factory site.

10 heads Simultaneous picking function

new features like 10 heads Simultaneous picking ( Interval 5 nozzles take material at the same time),

Components size shoud be 0805 inch and above size , like 3535 LED lamp beads .

( suggest use the electric feeder to avoid the problem of insufficient air supply)

QM10 pick and place machine packing details

machine size up to 1500*1735*1620mm,Packing size 4.3 CBM. gross weight 1750kg . Because the mass of the equipment is relatively large, you need a suitable transportation method. At present, most of them are exported by sea or rail.

Best seller SMT Machine :Qihe smt line products

-

Q10 SMT Automatic pick and place machine 10 Heads 100 Slots High Precision and High Efficiency SMT/LED Assembly

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802BX SMT pick and place machine 2heads 46slots desktop pnp mounter deluxe edition

-

QL41 SMT pick and place machine 4heads 8slots LED for 1.2meters led strip pick&place machine

-

Q8 SMT pick and place machine 8heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802AX SMT pick and place machine 2heads 29slots desktop deluxe edition SMT Pick&Place Machine

What is SMT used for?

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,and other products.

Small desktop pick and place machine TVM802A,TVM802B,TVM802AX,TVM802BX series suitable for beginners, for hobbiest or low vol usag.

Advanced level 4-head LED strip placement QL41 led machines and with rail universal series TVM925S,TVM926S,

Fully automatic 6-10-head placement QM61,QM62,QM81,QM10,machines, which are suitable for high volume mass production in factories.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, conveyor,connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.

How to choose the right smt pick and place robot?

SMT Pick and place robots can execute virtually all smd material handling operations both cost-efficiently and effectively — With several designs and configurations available in the market, it can be challenging to pick one that suits your operational needs. To help you make the right decision, some factors and features you should look out for when purchasing a pick and place robot.The most important thing is the operating system, then the hardware configuration, the types of components supported, and the speed of operation, the accuracy of placement, and the smt setup cost of the entire smt line .

Qihe smt pick&place machine is a professional operating system independently developed. It has more than ten years of user experience, combined with the algorithm improvement of world-renowned colleges, and the most advanced flying camera and motion system. It is your best choice. The system is friendly for beginners and professionals.

WHAT IS SMT PROCESS?

There are mainly three steps in SMT assembly line process flow: solder paste printing, components placement and reflow soldering.

- Solder Paste Printing

Its function in SMT line process is to print the solder-free paste on the pads of the PCB to prepare for the soldering of the components. The equipment used is a screen printing machine, located at the forefront of the SMT production line. - Components Placement

Its function is to accurately install the surface mount components on the fixed position of the PCB. The equipment used is a placement machine, located behind the screen printing machine in the SMT production line. - Reflow Soldering

Its function in SMT manufacturing line is to melt the solder paste so that the surface mount components and the PCB board are firmly bonded together. The equipment used is a reflow oven, located behind the placement machine in the fully automatic SMT production line.