Today author from qihe smt pick and place machine tell you about rapid proofing of multi-layer pcb boards for smt pick and place machine has the following difficulties:

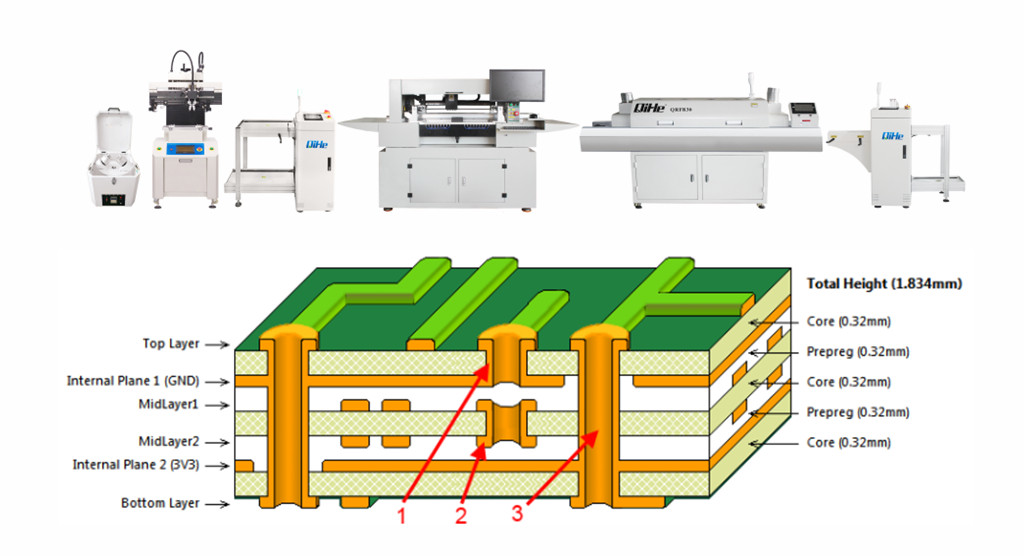

Interlayer alignment Due to the large number of layers in a multi-layer PCB board.

Most users have higher and higher calibration requirements for PCB layers.

Typically, the alignment tolerance between layers is controlled at 75 microns. Considering the large unit size of the multi-layer PCB board.

The high temperature and humidity in the graphics conversion workshop. The dislocation overlap caused by the inconsistency of different core boards.And the interlayer positioning method.

The alignment control of the multi-layer PCB board is more and more difficult.

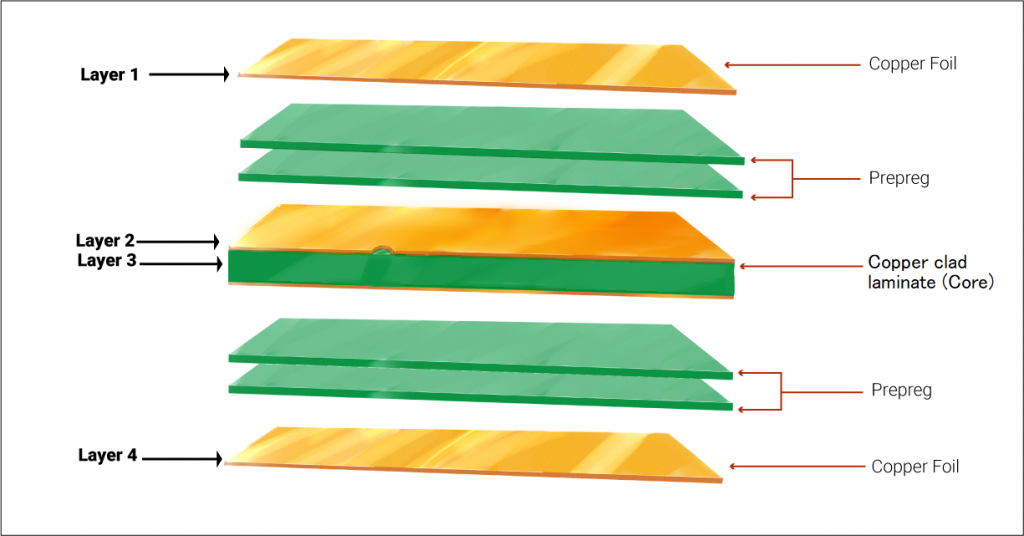

Internal circuit production The multi-layer pcb board adopts high TG, high speed, high frequency, thick copper, thin dielectric layer and other materials.

Which puts forward high requirements for internal circuit production and graphic size control. For example, the integrity of impedance signal transmission adds to the difficulty of internal circuit fabrication.

In the rapid proofing process of the pcb board, the width and line spacing are small,

open and short circuits are added, short circuits are added,

And the pass rate is low; there are many signal layers of thin lines, and the detection probability of AOI leakage in the inner layer is increased;

the inner core board is thin, easy to wrinkle, and poor exposure. ,

It is easy to bend when the etching machine is used; the high-level plate is mostly a system board, the unit size is large, and the product scrapping cost is high.

Compression manufacturing In the process of rapid proofing of pcb boards,

many inner core boards and prepreg boards are superimposed,

and defects such as sliding plates, delamination, resin voids and bubble residues simply appear in stamping production.

In the design of the laminate structure, the heat resistance, pressure resistance,

glue content and dielectric thickness of the material should be fully considered,

and a reasonable multi-layer circuit board material pressing plan should be formulated.

Due to the large number of layers of the pcb board, the expansion and contraction control and size coefficient compensation cannot be kept consistent,

And the thin interlayer insulating layer is simple, which leads to the failure of the interlayer reliability test.

Drilling In the process of rapid proofing of pcb boards, some boards have added difficulty in drilling roughness, drilling burrs and decontamination.

The number of layers is large, the total copper thickness and plate thickness are accumulated,

And the drilling tool is easy to break; the CAF failure problem cause

Read more: How to design multi layer PCB board for SMT PNPyou can choose a reflow oven to meets your need like qfr630,qrf835,qrf1235

stencil printer model qh3040,qp3250,qfa5060

Also we have different kinds of smt pick and place machine like tvm802a,tvm802b,tvm802ax,tvm802bx,tvm925s,tvm926s,ql41,qm61,qm62,qm81,qm10

Qihe SMT pick and place machine catalog

-

Automatic Screen Printing Machine RSE High Efficiency high Power Printing PCB

-

R5 Automatic Screen Printing Machine 2024 new listing SMD Solder Paste Printing

-

Q10 SMT Automatic pick and place machine 10 Heads 100 Slots High Precision and High Efficiency SMT/LED Assembly

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

QP5060 automatic solder paste printer stencil printer machine screen printer machine

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

RF8835LS up8/down8 Zones Reflow Oven solder welding

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

Qihe QM10 SMT pick and place machine

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.

WHAT IS SMT PROCESS?

There are mainly three steps in SMT assembly line process flow: solder paste printing, components placement and reflow soldering.

- Solder Paste Printing

Its function in SMT line process is to print the solder-free paste on the pads of the PCB to prepare for the soldering of the components. The equipment used is a screen printing machine, located at the forefront of the SMT production line.

- Components Placement

Its function is to accurately install the surface mount components on the fixed position of the PCB. The equipment used is a placement machine, located behind the screen printing machine in the SMT production line.

- Reflow Soldering

Its function in SMT manufacturing line is to melt the solder paste so that the surface mount components and the PCB board are firmly bonded together. The equipment used is a reflow oven, located behind the placement machine in the fully automatic SMT production line.