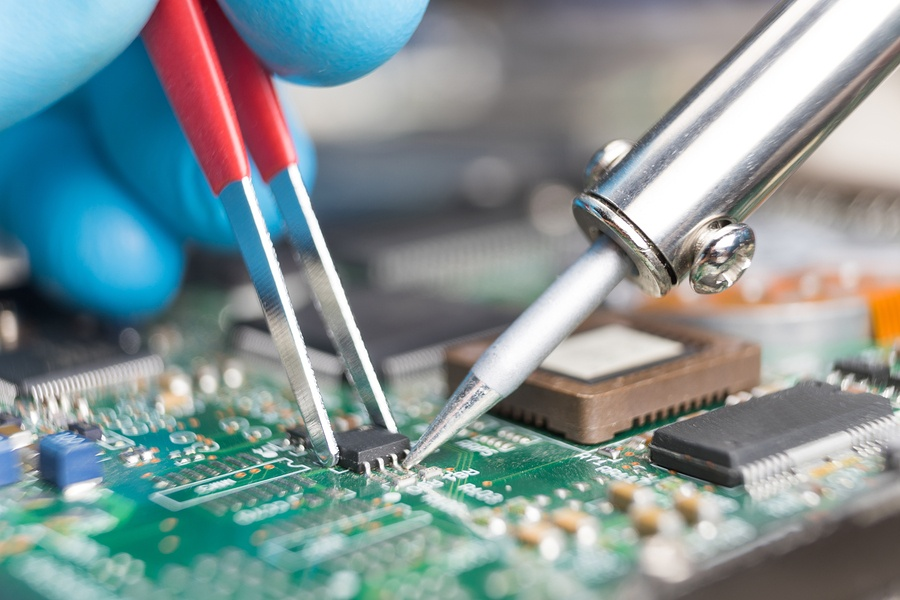

When customers inquire about SMT chip processing, they often ask whether you are using lead-free soldering or leaded soldering. We will tell customers that both lead-free and leaded soldering are available, and the prices are different. What is the difference between leaded soldering and why should lead-free soldering be used for SMT chip processing? When you use a precise smt pick and place machine to complete the placement, but you don’t get a satisfactory product after soldering? The quality of welding directly affects the final quality of the product.We will introduce the difference between leaded and lead-free soldering.

First, the difference between leaded and lead-free soldering is generally said:

Lead-free solder paste or lead-free solder paste welding, lead-free solder paste is environmentally friendly, leaded solder paste is not environmentally friendly, so the difference between lead and lead-free SMT chip processing is environmental protection and non-environmental protection

Second, the difference between lead and lead-free

a. Different alloy compositions:

The composition of tin and lead commonly used in lead processing is 63/37

The composition of lead-free alloy is SAC305,

Namely Sn: 96.5%, Ag: 3% and Cu: 0.5%.

Lead-free processes cannot be absolutely lead-free, but only contain very low levels of lead

b. Different melting points:

The melting point of lead and tin is 180°-185°, and the working temperature is about 240°-250°.

The melting point of lead-free tin is 210°-235°, and the working temperature is 245°-280°.

c. Cost difference:

Tin is more expensive than lead, and when the equally important solder is changed to tin, the cost of the solder also increases. Therefore, the cost of lead-free processing is much higher than the cost of leaded processing.

Lead-free processing costs 2.7 times the cost of leaded processing for wave and hand soldering, and about 1.5 times the cost of reflow soldering paste.

Why use lead-free soldering for SMT chip processing?

Now is the time to sum up this issue. Lead-free soldering is mainly about environmental protection. It is healthier for users who use the product and has a much lower impact on the environment. However, the cost of lead-free soldering will be higher, so the unit price of SMD processing will also be higher. Will be high, customers need to use lead-free or lead welding, need to be considered according to the use environment of the product, product price and profit, rather than blindly pursuing lead-free welding.

-

RF8835LS up8/down8 Zones Reflow Oven solder welding

-

QRF320 / QH320 Crawler-type 5 Zones SMT Reflow Oven solder welding

-

QR962C Desktop SMT Reflow Oven solder welding

-

QRF1235 12 Zones SMT Reflow Oven solder welding with guide rail

-

QRF830 8 Zones SMT Reflow Oven solder welding with cabinet

-

QRF835 with rail 8 Zones SMT Reflow Oven solder welding

-

QRF1230 12 Zones SMT Reflow Oven solder welding with cabinet

-

QRF630 6 Zones SMT Reflow Oven solder welding with cabinet

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.