Qihe smt pick and place machine joined in 2022 Productronica India Exhibition.

We will show the QM10 fully automatic SMT line ,and popular smt pick and place machine models TVM925 ,TVM802AX and reflow oven machine such as QRF830 ,etc.

The following information is the exhibition details:

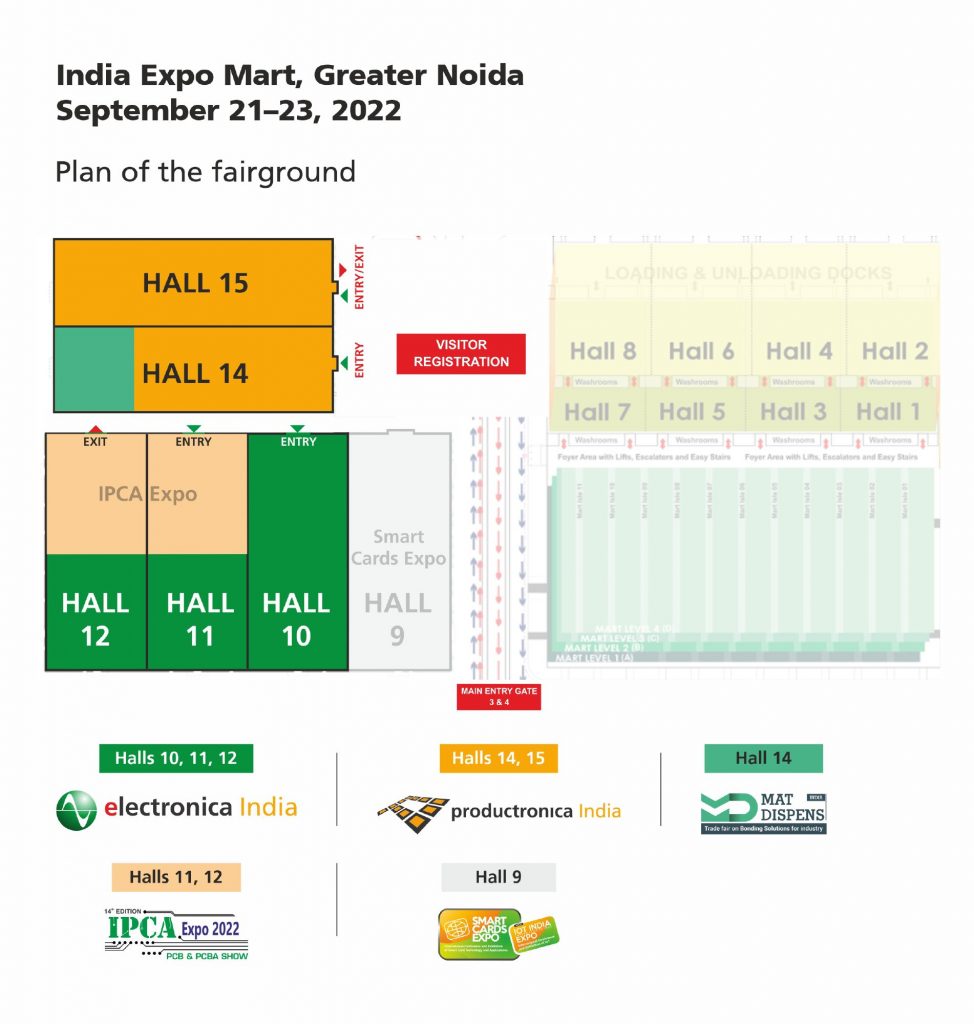

Exhibition: 2022 Productronica India Exhibition

Exhibitor:Qihe India Pvt Ltd & MR technology

Stall Number: PA-25

Hall number: 14

Exhibition Date: 2022-September-21st to 23rd

Location: India Expo Mart, Greater Noida, Delhi NCR, India

link:https://www.productronica-india.com/en/

productronica India is the innovative platform for production technologies which are experiencing a strong increase in demand due to India’s emerging electronics manufacturing market.

productronica India demonstrates a close link to the world’s leading trade fair productronica in Munich, Germany. It takes place in parallel to electronica India.

Thus, the entire value-added chain of the electronics industry is presented during one event.

Benefits to visit

There are plenty of good reasons to attend productronica India. It will give you a broad overview of the entire electronics production industry and give you new drive for your business success. See for yourself.

- World’s leading trade-fair network

No other trade fair benefits from being embedded in a worldwide cluster as much as productronica India. productronica India brings together local and international suppliers of electronics manufacturing equipment. At the same time, leaders from the electronics industry meet at electronica India, which creates the best communication and business environment for both sides. - We offer high service quality and international standards

As the organizer of leading events in Munich since 1964, we also have a great deal of experience with productronica in India, allowing us to provide you the most efficient trade-show expertise as well as market knowledge. - Industry and marketing know-how that is difficult to emulate

We have strong alliances with the government of India, the Ministry of Electronics and Information Technology (MeitY), the Ministry of Home Affairs and Ministry of External Affairs. We also enjoy the support of national and international associations such as the Consortium of Electronic Indus-tries in Karnataka (CLIK), Electronic Industries Association of India (ELCINA), India Electronics & Semiconduc-tor Association (IESA), IPC India—Association Connecting Electronics Industries, National Small Industries Cor-poration (NSIC), SEMI India—Semiconductor Equipment and Materials International, German Electrical and Electronic Manufacturers Association (ZVEI) and many more, resulting in the outstanding quality of electronica India and productronica India. - We have a high-quality supporting program

With the help of associations and other industry partners, productronica India’s special lectures are always adapted to the market’s needs. Speakers include experts, executives and researchers from leading companies and scientific research institutions. This much experience, knowledge and expertise is not available in this format anywhere else. Details regarding the program of events are available here. - Attractive synergies for visitors

Being co-located with electronica India creates attractive synergies and added value for visitors. It gives them the opportunity to gain insights into the latest technologies and applications in all electronics sectors.

Exhibition sectors

productronica India is the only event of its kind to showcase the entire value chain in electronics production—from technologies and components to software and services.

Exhibition sectors of productronica India

Semiconductor and display manufacturing

Photovoltaics production, production technologies for batteries and electrical energy storage

Micronano production

PCB and other circuit-carrier manufacturing

Component mount technology

Soldering technology and joining

Organic and printed electronics

Hybrid-component manufacturing

Coilware production

LED production and discrete devices

Technologies for cable processing and connectors

Materials processing (electronic and chemical)

Manufacturing and process software

Test and measurement, quality assurance

Product finishing

Production logistics and material-flow technology

Production subsystems

Production materials/equipment, environmental technology and clean-room technology

Electronic Manufacturing Services (EMS)

Semiconductors and display manufacturing

The advent of low-cost computers and integrated circuits has transformed modern society. Integrated circuits are now used in virtually every electronic device and have revolutionized the world of electronics. Otherwise, this is a technology that influences our daily lives: Smartphones, TVs, driver assistance—displays of all kinds are installed in all of these applications. Each of these reasons for innovative production lines and processes that gradually change to meet specific needs shape the applications side. Visit productronica India to learn more about the latest developments in semiconductor and display manufacturing.

Photovoltaics production, production technologies for batteries and electrical energy storage

Photovoltaics is a rapidly growing market: The Compound Annual Growth Rate (CAGR) of PV installations was 44 percent between 2000 to 2014. When it comes tophotovoltaics module production in 2014, China/Taiwan held the lead with a share of 69 percent. Europe contributed with a share of six percent; Japan and USA/CAN each contributed four percent (Fraunhofer ISE). productronica India is a perfect platform for photovoltaics production technology. Production technologies for batteries and electrical energy storage will continue to increase in importance in the future. Particularly given the fact India has launched a special energy policy.

Micronano production

The production of microelectromechanical systems (MEMS) is resulting in pioneering improvements in the functionality of small microphones, cameras and signal filters. The use of MEMS is also making it possible to develop entirely new products such as affordable multiple-axis inertial sensors for measuring movement and digital optical micro-mirror arrays for industrial and medical applications. Everything that entails including micronano production is on display at productronica India.

PCB and other circuit-carrier manufacturing

Whether single-sided, double-sided or multi-layer, PCBs are the heart of all but the simplest electronic devices. Advanced PCBs may contain components—i.e. capacitors, resistors or active devices—that are embedded in the substrate. PCBs require an additional design step to lay out the circuit, but manufacturing and assembly can be automated. Exhibitors at productronica India will be happy to lead you through this process.

Component mount technology

Surface mounting lends itself well to a high degree of automation, reducing labor costs and greatly increasing production rates. Components can be supplied mounted on carrier tapes. Surface-mount components can be approximately one-quarter to one-tenth the size and weight of through-hole components, and passive components are much cheaper. See state-of-the-art equipment including soldering technology and automated optical inspection at productronica India.

Soldering technology and joining

Currently, mass-production printed circuit boards (PCBs) are mostly wave soldered or reflow soldered, though hand soldering of production electronics is also still standard practice. productronica India gives you access to information about soldering facilities and accessories, coating equipment as well as all the latest news about soldering, dispensing and joining technology. Come to productronica India!

Organic and printed electronics

Organic electronics are based on the combination of a new class of materials and large-area, high-volume deposition and patterning techniques. This technology is still in its early stage, but will increasingly enter the market and be shown at productronica India.

Hybrid-component manufacturing

Hybrid component manufacturing is unbeatable, particularly for electronic, sensor and mechatronic applications. Hybrid components made of metal, plastic and ceramics continue to conquer more and more sales potential in medical technology, electrical installation and power engineering. Find out more at productronica India.

Coilware production

Whether it comes to electric motors, transformers, generators or magnetic-field sensors: Winding coils is an art. Coilware production is “magnetic field design” at the highest level. Depending on the application, using small material quantities, small losses, high fill factors and high energy efficiency are critical factors of success. When power is constant, reducing the volume and weight of high-energy components increases the flow of heat to be dissipated—a challenge that can only be met using carefully coordinated materials, design and process engineering.

LED production and discrete devices

LEDs play an indispensable role in lighting today. The Government and industries are turning to LED lighting as an ideal source because it is more energy efficient. LEDs are also used in a number of applications areas including indoor and outdoor lighting, signage, the industrial sector, the automobile industry, the medical sector and many more. productronica India is a perfect platform for the LED manufacturing industry due to the presence of the entire ecosystem in electronics manufacturing and production technology.

Technologies for cable processing and connectors

Design, shielding and the materials used to produce cables determine their mechanical and electrical properties. Everything that entails including the use of crimping machines is on display at productronica India.

Materials processing (electronic and chemical)

From mechanical processing to thermal treatment, chemical and electroplate processing and even laser material-processing systems will draw your attention at productronica India.

Manufacturing and process software

Compare leading process manufacturing systems software to find the right solution for your electronic manufacturing business. ERP, machine to machine and Industry 4.0 are just some of the developments that are relevant for success in this industry.

Test and measurement, quality assurance

When developing electronic circuits and systems, advanced testing equipment is essential. Practical electronics engineering and assembly call for a wide range of electronic testing equipment, ranging from the very simple and inexpensive to extremely complex and sophisticated systems such as automatic optical inspection (AOI). The test and measurement segment adheres to the fair’s “application-oriented” principle and focuses on the latest test and measurement solutions such as display digital circuit testing, board-level testing, component testing and many other popular applications.

Product finishing

The topics in this segment at productronica India are core elements of product finishing: They include repair and rework, programming equipment, memory components and everything that is related to the topic of protective coating and potting hybrids as well as housings and electronic protective devices (EMC/ESD).

Production logistics and material-flow technology

Production logistics and material-flow technology apply mainly to advance modeling of supply chain management. Exhibitors at productronica India will be happy to lead you through this process, which covers everything from information acquisition, purchasing, merchandise management systems to logistics management and material-flow control, etc. Come to productronica India!

Production subsystems

Visit productronica India and gather information about assembly and handling technology as well as drive technology and systems for production data acquisition.

Production materials/equipment, environmental technology and clean-room technology

The topics in this segment are important elements in electronics development and production: Besides preliminary products and semi-finished goods, everything related to the topic of production materials and equipment as well as environmental and clean-room technology can be found here.

Electronic Manufacturing Services (EMS)

Previously, the business model for the EMS industry was to specialize in large economies of scale in manufacturing. This means that customers do not have to keep huge inventories of products, and EMS companies can respond to sudden changes in demand more quickly and efficiently. For quite some time, EMS companies have also provided design-service assistance. EMS specialists are located throughout the world. They vary in terms of production capabilities and comply with various quality standards and regulatory requirements. If this is what you are looking for, visit productronica India.