The main purpose of PCB baking is to remove moisture and avoid moisture. today author from qihe smt pick and place machine tell you about it with you .

Remove the moisture contained in the PCB or absorbed from the outside world. Because some materials used in the PCB itself are easy to form water molecules. In addition, after the PCB is produced and placed for a period of time, it has the opportunity to absorb the moisture in the environment, and water is one of the main reasons for the explosion or delamination of the PCB. It is also the cause of oxidation.When you get a good PCB board, you can go to the next production through the smt pick and place machine and reflow soldering .So it is important baking step before SMT process and reflow soldering .

Condition setting for PCB baking

a. The PCB is within 2 months of the production date and is well sealed. After unpacking, it is placed in a temperature and humidity controlled environment (≦30°C/60%RH, according to IPC-1601) for more than 5 days. Before going online Bake at 120+/-5°C for 1 hour.

b. The PCB has been stored for 2 to 6 months beyond the production date, and it needs to be baked at 120+/-5°C for 2 hours before going online.

c. The PCB has been stored for 6 to 12 months beyond the production date, and it needs to be baked at 120+/-5°C for 4 hours before going online.

d. It is basically not recommended to use PCBs that have been stored for more than 12 months beyond the production date, because the adhesive force of multi-layer boards will age with time, and quality problems such as unstable product functions may occur in the future. In addition, the production process also has risks such as explosion and poor tin consumption.

e. All baked PCBs must be used within 5 days, and unprocessed PCBs must be re-baked at 120+/-5°C for another 1 hour before going online.

How to stack when PCB is baked

When baking large-sized PCBs, they should be placed flat and stacked. It is recommended that the number of a stack should not exceed 30 pieces. Within 10 minutes after baking, the oven should be opened to take out the PCB and lay it flat to cool it down. Plate bending jig. Vertical baking is not recommended for large-size PCBs, which are easy to bend.

When baking small and medium-sized PCBs, they can be placed flat and stacked. It is recommended that the number of a stack should not exceed 40 pieces. It can also be used upright. It is cooled, and the anti-bending jig needs to be pressed after baking.

Precautions when PCB baking

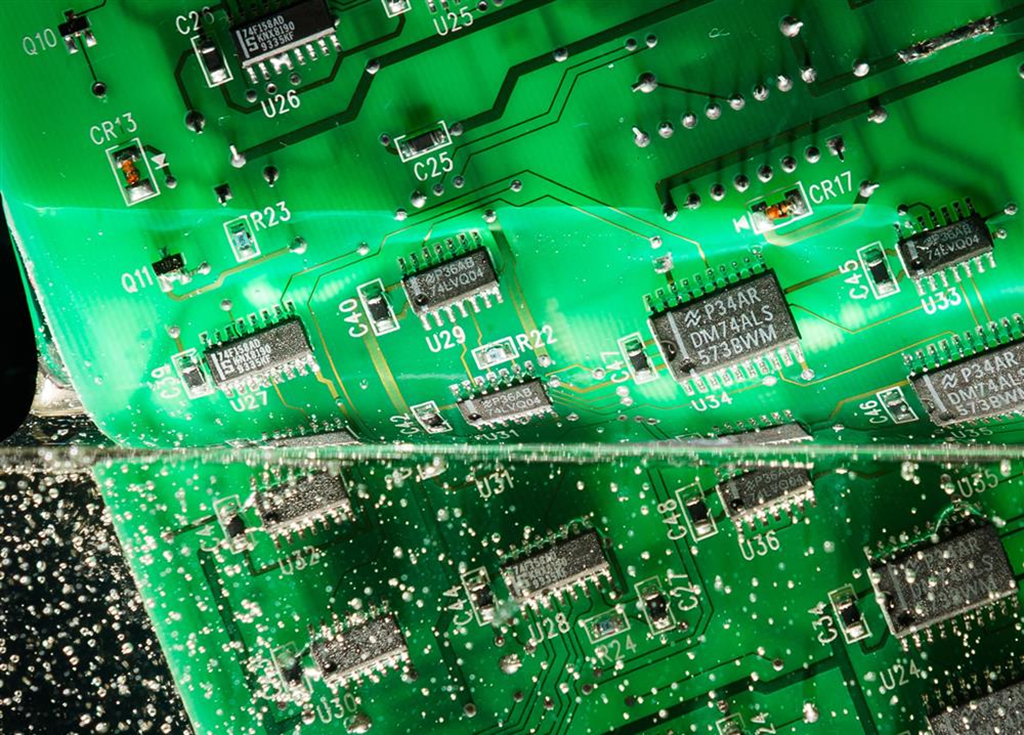

The baking temperature should not exceed the Tg point of the PCB, and generally it should not exceed 125°C. In the early days, the Tg point of some lead-containing PCBs was relatively low, and now the Tg of lead-free PCBs is mostly above 150°C.

The baked PCB should be used as soon as possible. If it is not used, it should be vacuum packed as soon as possible. If exposed to the shop for too long, it must be re-baked.

Remember to install ventilation drying equipment in the oven, otherwise the steam from baking will remain in the oven to increase its relative humidity, which is not good for PCB dehumidification.

From the point of view of quality, the fresher the PCB solder is, the better the quality will be after passing through the oven. Even if the expired PCB is used after baking, there will still be a certain quality risk.

Disadvantages of PCB Baking

Baking will accelerate the oxidation of the PCB surface coating, and the higher the temperature and the longer the baking time, the more disadvantageous it is.

High temperature baking is not recommended for boards with OSP surface treatment, because the OSP film will degrade or fail due to high temperature. If you have to bake, it is recommended to bake at a temperature of 105+/-5°C, and preferably not more than 2 hours. It is recommended to use it up within 24 hours after baking.

Qihe smt pick and place machine catalog

-

Q10 SMT Automatic pick and place machine 10 Heads 100 Slots High Precision and High Efficiency SMT/LED Assembly

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802BX SMT pick and place machine 2heads 46slots desktop pnp mounter deluxe edition

-

QL41 SMT pick and place machine 4heads 8slots LED for 1.2meters led strip pick&place machine

-

Q8 SMT pick and place machine 8heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802AX SMT pick and place machine 2heads 29slots desktop deluxe edition SMT Pick&Place Machine