Description

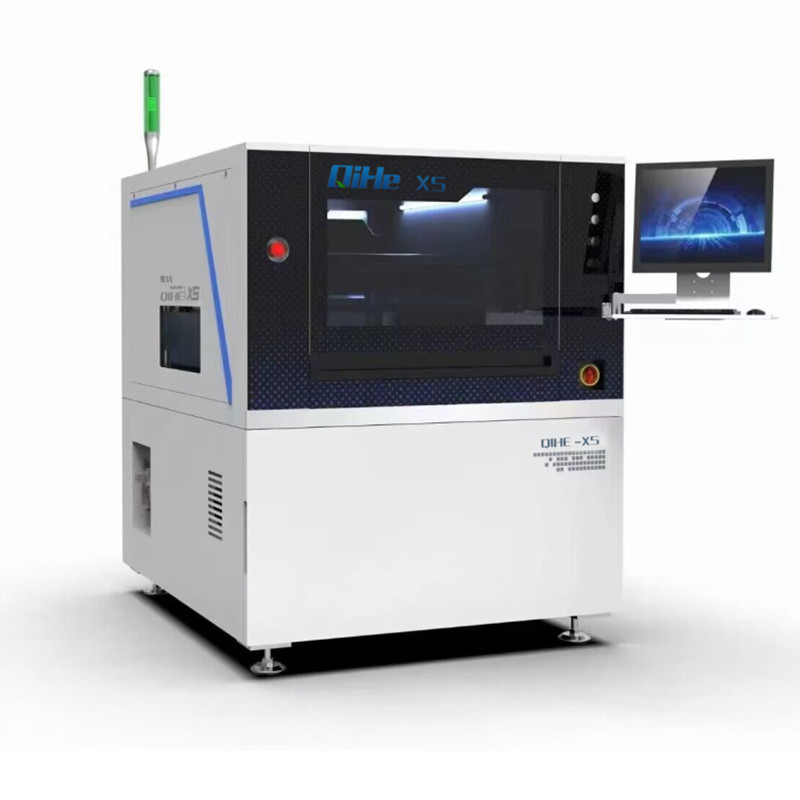

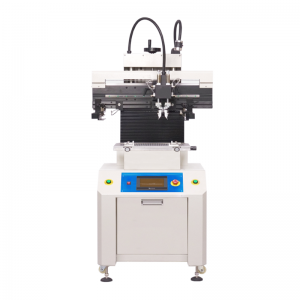

QP5060 automatic solder paste printer (fully automatic vision solder paste printer) stencil printer machine screen printer machine The whole machine is fully controlled by servo system.Automatic pressure feedback system.Multifunctional image processing system.Precise PCB transportation system.Intelligent PCB holding device.User-friendly operation interface.

Using advanced image visual recognition system, independent control and adjusted lighting, high-speed moving lens, accurate PCB and template alignment, ensure that the printing accuracy of ± 0.025mm.

High precision step servo motor drive and PC control to ensure printing accuracy and stability, accurate image recognition technology has ± 0.01mm repeated positioning accuracy.

Suspension printing head, specially designed with high precision step motor direct drive scraper lift, pressure, speed and stroke are accurately controlled by PC motion control card, make the printing quality more uniform and stable; scraper beam after specially optimized structure design, light and beautiful appearance.

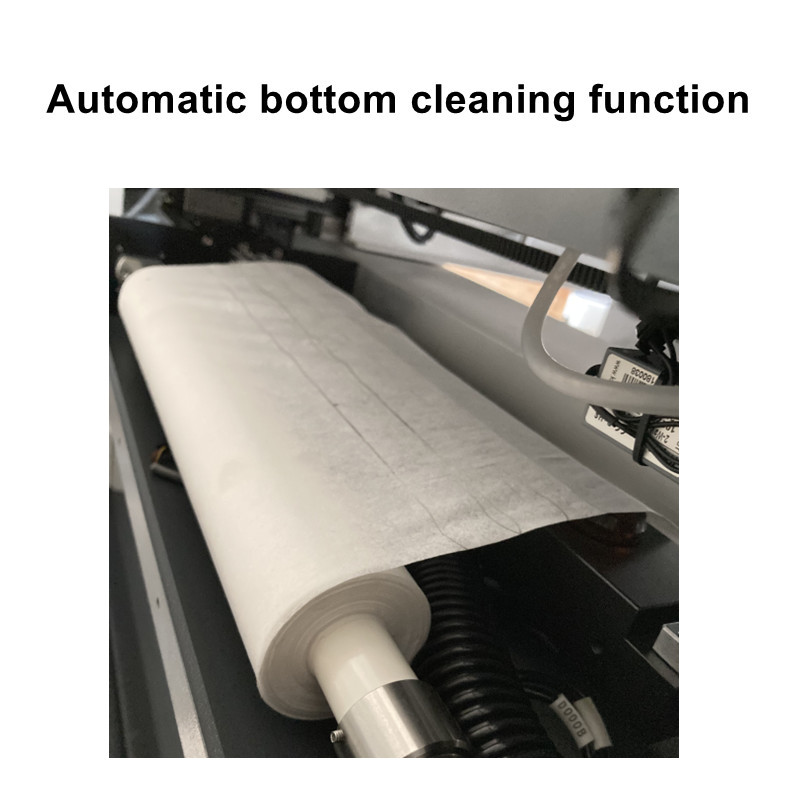

You can choose manual / automatic bottom cleaning function, automatic, no auxiliary bottom cleaning function, programmable control dry, wet cleaning, cleaning interval can be freely selected, can completely remove the residual tin paste in the mesh, to ensure the printing quality.

The combined workbench can set the thimble according to the size of the PCB substrate,making the clip more fast and easy. Multifunctional plate processing device can automatically locate and clamp PCB platesof various sizes and thickness, with movable magnetic thimble, effectively overcome thedeformation of the plate and ensure uniform printing process.

Automatic solder paste printer With “Windows XP / Windows 7 window” operation interface and rich software functions, with a good man-machine dialogue environment, simple operation, easy, easy to learn, easy to use.

X5 automatic solder paste printer has the function of fault self-diagnosis sound, optical alarm and prompt fault cause.Whether the single / double-sided PCB substrate can be operated.

Complete machine parameters

| Repeat Positioning Accuracy | Repeat positioning accuracy | ±10 um at 6 Sigma |

| Printing Accuracy | Printing accuracy | ±25um at 6 Sigma |

| Cycle Time | periodic time | <7s (excluding printing, cleaning time) |

| Product Changeover | Change time | <5Min |

| Air Required | Use the air | 4.5~6Kgf/cm2 |

| Power Input | source | AC 220V± 10% 50 / 60 HZ single-phase |

| Control Method | controlling means | PC Control |

| Machine Dimensions | Equipment size | 1160(L)×1380(W)×1485(H)mm |

| Weight | weight | About 800kg |

| Maximum Power | maximum power | 3KW |

| Temperature | temperature | 25±3℃ |

| Humidity | humidity | Relative humidity of 30% -70% |

| Acoustic Noise Level | noise level | Less than 70dB |

Printing parameters

| Frame Size | The minimum size of the mesh frame | 470×370mm |

| Maximum size of mesh frame | 737×737 mm | |

| PCB Size | PCB lower limit | 50×50 mm |

| PCB maximum dimensions | 510×330 mm | |

| PCB Thickness | PCB plate thickness | 0.4~5 mm |

| PCB Distor ti on | PCB plate distortion degree | 1% (diagonal measurement) |

| Support System | Support mode | Magnetic thimble, manually adjustable jacking platform |

| Clamp System | The clamping way | Unique flexible side clamp |

| Table Adjustment Ranges | Workbench adjustment scope | X:±7.5mm; Y:±7.5mm; θ :±2° |

| Conveyor Speed | Guide rail transmission speed | Max 1500mm / S Programmable |

| Conveyor Height | Guide rail transmission height | 900±40mm |

| Conveyor Direction | Transfer direction | Left-right, right-left, left-left, right-right |

| Squeegee Pressure | Scrapper pressure | 0~10Kgf/cm2 |

| Printing Speed | print speed | 1~200mm/sec |

| Squeegee Angle | Scrapper Angle | 60° (standard), 55°, 45° |

| Squeegee Type | Scrapper type | Steel scraper, rubber scraper |

| Cleaning System | Cleaning method | Dry cleaning, wet wash, (programmable) |

Optical system (Fiducially mark optical alignment mark)

| Fiducial Mark Detection | Marker point detection | A single CCD camera was identified through the mesh board and the two marking points on the substrate |

| Alignment Mode | Adjust the way | The position of PCB and the mesh board is detected by camera, and the alignment can realize the alignment of the mesh board and the substrate |

| Fiducial Mark Shape | Mark point shape | Any shape |

| Fiducial Mark Size | Tagged point size | It can be made into various shapes of holes with a diameter or a side length of 1mm~2.5mm, allowing for a deviation of 10% |

| Fiducial Mark Type | Tagged point type | Empty type: thin copper material around Semi-permeable air type: in the middle of the transparent or translucent coating materials can be used in nickel, bronze, etc |

| Fiducial Mark Requ irement | Mark point requirements | The coating surface of the marking points shall be flat and smooth. |

What is SMT in engineering?

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,automatic solder paste printer and other products.

Small desktop pick and place machine TVM802A,TVM802B,TVM802AX,TVM802BX series suitable for beginners, for hobbiest or low vol usag.

Advanced level 4-head LED strip placement QL41 led machines and with rail universal series TVM925S,TVM926S,

Fully automatic 6-10-head placement QM61,QM62,QM81,QM10,machines, which are suitable for high volume mass production in factories.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/