Surface mount technology (SMT) mainly includes: solder paste printing, precision placement, reflow soldering.

Among them, the quality of solder paste printing has a great impact on the quality of surface mount products, according to the industry review and analysis of about 60% of the returned circuit board is caused by poor solder paste printing. In solder paste printing, there are three important parts: solder paste, stencil template and printing equipment, if the correct choice, you can get good printing results, as discussed below:

Solder paste

Solder paste is a mixture of solder powder and paste flux with flux function (rosin, thinner, stabiliser, etc.) into a paste. Solder paste is viscous, in printing, by the scraper’s thrust, its viscosity decreases, when it reaches the stencil opening holes, the viscosity reaches the lowest, so it can be smoothly through the template holes sink to the PCB pads. With the cessation of external forces, the viscosity of the paste and quickly back up, so that there will be no printing and shaping of the collapse and diffusion, to get good printing results.

Viscosity is an important characteristic of solder paste. Dynamically, during the printing stroke, the lower the viscosity the better the fluidity, easy to flow into the stencil aperture; from a static point of view, after the end of the printing, the solder paste stays in the stencil aperture, its viscosity is higher, then keep its filling shape, will not collapse downward.

Factors affecting solder paste viscosity:

- The effect of solder paste alloy powder content on viscosity – the increase of alloy powder in solder paste causes the increase of viscosity;

- The effect of paste alloy powder particle size on viscosity – viscosity decreases when particle size increases;

Ø The printability of solder paste with fine particles is better, especially for high-density, narrow-pitch products, due to the small size of the stencil opening, it is necessary to take small particles of alloy powder, otherwise it will affect the print release.

Ø Advantages of small particle alloy powder: good printability, high clarity of printed graphics.

Ø Disadvantages of small particle alloy powder: easy to collapse, easy to be oxidised if the surface area is large.

| The relationship between SMT component pin spacing and solder particles. | |||||

| Pin spacing(mm) | Above 0.8 | 0.65 | 0.5 | 0.4 | |

| Particle diameter (um) | Below 75 | Below 60 | Below 50 | Below 40 | |

3.The effect of temperature on the viscosity of the paste: temperature increases, viscosity decreases, the best ambient temperature for printing 23 ± 3 ℃;

4. the effect of shear rate on the viscosity of the paste: shear rate increases the viscosity decreases.

The expiration date of solder paste and the environment of preservation and use:

Ø General solder paste in the unopened cap state, 0-10 ℃ conditions can be stored for 6 months, after opening the seal should be used up as soon as possible;

Ø The environment for the use of solder paste is: the temperature of the SMT room is required to be 20-26 ℃, humidity is 40-60%;

Ø Unopened solder paste, in the ambient temperature and humidity conditions of the preservation time ≤ 48 hours;

Ø After opening the lid solder paste, the storage time under the condition of ambient temperature and humidity ≤ 18 hours;

Ø Use time on the stencil ≤ 12 hours;

Ø After printing the solder paste on the line stay time ≤ 2 hours;

Ø After opening the tin until reflow soldering time ≤ 18 hours.

Defects caused by solder paste:

- Not soldered by immersion

Ø Bad flux activity;

Ø Metal particles are highly oxidized; - No rolling in printing

Ø Inappropriate flow, e.g. viscosity, thixotropic index

Ø Unsuitable viscosity; - Bridging Ø Collapse of solder paste;

- insufficient solder Ø clogging of stencil holes by solder paste due to large alloy powder particles, incorrect shape or non-printability;

- solder balling Ø solder paste collapse;

Ø Solvent spattering in reflow soldering;

Ø Oxidation of metal particles.

Stencil Stencils

The main function of the stencil is to accurately apply the solder paste on the PCB needs to be coated with solder paste pads. In the solder paste printing process stencil template processing quality directly affects the printing quality of solder paste, stencil thickness and opening size determines the amount of solder paste printing, and stainless steel laser template need to be made through outsourcing. Therefore, before the outsourcing process must do a good job in the template thickness and design of the opening size and other parameters of the confirmation to ensure that the printing quality of the solder paste.

Usually in a PCB on both the 1.27mm pitch components, there are also narrow-pitch components, 1.27mm or more pitch components need stainless steel plate 0.2mm thick, narrow-pitch components need stainless steel plate 0.15-0.10mm thick, this time according to the majority of components on the PCB to determine the thickness of the stainless steel plate, and then through the individual components of the pad openings Then by expanding or reducing the size of individual component pad openings to adjust the amount of solder paste leakage.

If the amount of solder paste required on the same PCB component is relatively large disparity, you can narrow-pitch components at the template for local thinning, but the thinning process has higher processing costs. Therefore, you can use a compromise method, the thickness of stainless steel plate can take the middle value, for example: the same PCB components require 0.20mm thick, some other components require 0.15-0.12mm thick, this time the thickness of stainless steel plate can be selected 0.18mm. openings for general components can be based on 1:1, for the requirements of the amount of solder paste more than a large Chip components as well as the opening of the PLCC Area should be expanded by 10%. For the pin spacing of 0.5mm, 0.65mm QFP and other devices, the opening area should be reduced by 10%.

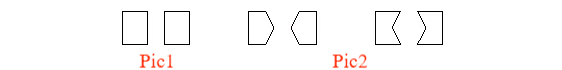

Appropriate shape of the opening can improve the mounting effect, for example: when the size of Chip components less than 1005, 0603, due to the distance between the two pads is very small, the paste on the pads of the two ends of the patch in the bottom of the component is easy to stick, reflow soldering is very easy to produce the bottom of the components of the bridging and solder beads. Therefore, the processing template can be a pair of rectangular pads (Pic 1) opening the inner side of the modification into a sharp angle shape or bow (Pic 2, Chip component opening shape), reduce the amount of solder paste at the bottom of the component, which can improve the solder paste adhesion at the bottom of the component when SMD.

Printing Equipment

Printing machine is the solder paste printing to the PCB board equipment, it is the process and quality of the largest impact of the equipment.

At present, the printing machine is mainly divided into: manual printing machine, semi-automatic printing machine and automatic printing machine.

Ø Semi-automatic printing machine:

Simple operation, fast printing speed, simple structure, the shortcomings are: printing process parameters can be controlled by fewer points, printing accuracy is not high, the solder paste off poor, generally applicable to more than 0603 components, pin spacing greater than 1.27mm PCB printing process.

Ø Fully automatic printing machine:

Printing centering accuracy is high, the solder paste release effect is good, the printing process is more stable, suitable for dense device printing of narrow-pitch components; drawbacks: high maintenance costs, the operator’s knowledge of the level of higher requirements.

SMT printing process parameters

- Alignment of graphics

Align the substrate and stencil on the table so that the pad pattern of the substrate and the aperture pattern of the stencil are exactly the same. - Squeegee and stencil angle

The smaller the angle between squeegee and stencil, the greater the downward pressure, easy to inject the solder paste into the mesh, but also easy to squeeze the paste to the bottom surface of the stencil, resulting in paste sticking. General scraper and stencil angle of 45-60o. At present, most of the automatic and semi-automatic printing machines use 60o. - Paste input quantity

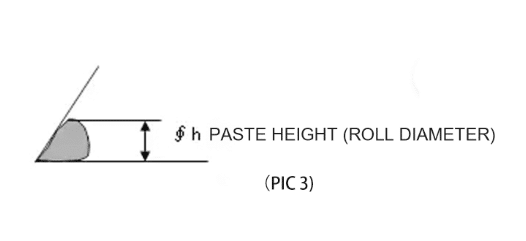

Too little into the amount of solder paste, easy to cause poor filling, leakage of printing less printing; too much into the paste, easy to cause the paste can not form a rolling movement, the paste can not be scraped clean, resulting in poor printing and molding; and too much solder paste for a long time exposed to air is not suitable for the quality of the paste, the amount of paste into the # h = 13-23 is more appropriate (Pic 3).

During production, the operator checks the height of the solder paste strip on the stencil every half hour, and every half hour moves the paste on the stencil beyond the length of the squeegee to the front of the stencil with a bakelite squeegee and distributes the paste evenly.

- Squeegee pressure

Squeegee pressure is also an important factor affecting printing quality. Squeegee pressure actually refers to the depth of the squeegee drop, the pressure is too small, the squeegee is not close to the surface of the stencil, in addition to the pressure is too small will make the surface of the stencil residual layer of solder paste, easy to cause printing molding bonding and other printing defects. - Printing speed

Due to the squeegee speed and paste consistency is inversely proportional to the relationship, PCB has a narrow pitch, high-density graphics, the speed should be slower. If the speed is too fast, the squeegee through the stencil opening time is relatively too short, the paste can not fully penetrate into the openings, easily caused by the paste molding is not full or leakage of printing and other printing defects.

Printing speed and squeegee pressure there is a certain relationship between the ideal squeegee speed and pressure should be just to scrape the paste from the surface of the stencil. - Printing gap

Printing gap is the distance between the stencil and the PCB, related to the printing of the paste in the PCB on the amount of retention. - Stencil and PCB separation speed

After the printing of solder paste, the stencil left the PCB instant speed that is the separation speed, it is related to the parameters of the printing quality. In the narrow pitch, high-density printing is most important. Advanced printing equipment, the stencil leaves the solder paste graphics with 1 or more tiny stay process, that is, multi-stage release, which ensures access to the best printing molding. - Cleaning mode and cleaning frequency

Stencil contamination is mainly caused by the overflow of solder paste from the edge of the aperture, if not cleaned in time, it will contaminate the surface of the PCB, the residual solder paste around the aperture of the stencil will harden, and in severe cases, it will also clog the aperture of the stencil.

Cleaning the bottom of the stencil is also a factor in ensuring the quality of printing, should be based on the solder paste, stencil material, thickness and aperture size to determine the cleaning mode and cleaning frequency.

The main factors affecting the quality of solder paste printing

- First is the quality of the stencil:

The thickness of the stencil and the size of the opening determines the printing quality of the solder paste. Too much paste produces bridging, too little paste produces insufficient paste or soldering. The shape of the stencil opening and the smoothness of the opening wall also affect the quality of mold release. - Next is the quality of solder paste:

The viscosity of the paste, the rolling of the printing, the service life at room temperature, etc. will affect the printing quality. - Printing process parameters:

Squeegee speed, pressure, squeegee and stencil angle and paste viscosity between the existence of certain constraints. Therefore, only the correct control of these parameters, in order to ensure the printing quality of the paste. - Equipment precision:

In the printing of high-density narrow-pitch products, the printing accuracy of the printing machine and repeat printing accuracy will also play a certain impact. - Environmental temperature, humidity, and environmental hygiene:

Ambient temperature is too high will reduce the viscosity of the paste, humidity is too large when the paste will absorb moisture in the air, humidity is too small will accelerate the solvent evaporation in the paste, the environment in the dust mixed into the paste will make the solder joints to produce pinholes and other defects.

As can be seen from the above introduction, the factors affecting the quality of printing are very many, and printing solder paste is a dynamic process. Therefore, the establishment of a complete set of printing process control documents is very necessary, the choice of the correct solder paste, stencil, and combined with the most appropriate printer parameter settings, can make the entire printing process more stable, controllable and standardized.