Author:Lucy Liang

SMT is surface assembly technology (Surface Mounted Technology) (Surface Mounted Technology acronym), is currently the most popular electronic assembly industry, a technology and process, SMT patch refers to a series of PCB-based processing process of the abbreviation. So SMT patch is produced by which equipment, SMT production process and how it is? Here for you to introduce the SMT equipment, SMT production line cost, and SMT process technology and peripheral items to recognize and pay attention to.

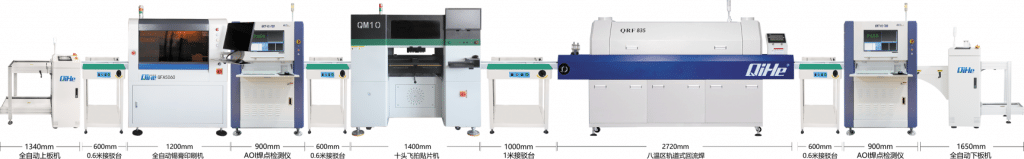

- Equipment to be used in SMT production lines

There are seven kinds of commonly used equipment: on the board machine (Loader), suction board machine (Stacker), printing machine (Solder printer), high-speed mounter (Highspeed mounter), connecting table (Coveryor) generalized mounter (Multi function mounter), reflow (Reflow), Under the board machine (Unloader), automatic optical inspection machine (AOI), perspective detector (X-RAY), in addition, to normal production must be equipped with an air compressor to the machine air supply.

- The role of each device in the SMT production line

1、Board loading machine: PCB is placed in the Rack and automatically fed to the board sucking machine.

2、Suction board machine: automatically absorb PCB placed on the track, transfer to the printing machine.

3、Printing machine: Print the solder paste or red glue onto the PCB completely through the stencil.

4、High-speed mounter: use the equipment to edit the program will be components mounted on the designated parts position, can be mounted SOP 28pin below the rolled parts, which is characterized by mounting speed.

5、Connection table: used for SMT production line connection between the PCB can also be used for buffering, inspection, test zhi test or electronic components manual insertion dao installation.

6、general-purpose mounter: the use of equipment to edit the program will be components mounted on the specified parts position, can be mounted SOP 28pin or more (including high-speed machine can be mounted on the components) rolls, trays or tubes of packaging components. Characterized by high accuracy, diversification, but the speed of mounting is inferior to the high-speed machine.

7、 reflow soldering: SMT solder paste or red glue using the temperature to set the appropriate temperature profile so that the solder paste and parts to complete the welding action.

8、under the board machine (Unloader): through the transmission track, receiving the board in the magzine.

9、optical detector: automatic optical inspection, is based on optical principles to detect common defects encountered in the production of welding equipment. aoi is a new test technology that emerged in recent years, but the rapid development of many manufacturers have launched aoi test equipment. When the automatic inspection, the machine automatically scans the PCB through the camera, collects the image, the tested solder joints are compared with the qualified parameters in the database, and after image processing, the defects on the PCB are checked and the defects are displayed/labeled through the monitor or automatic sign for maintenance personnel to fix.

10、 X-ray machine: mainly used to detect all kinds of industrial components, electronic components, circuit internal. For example, socket plug rubber internal line connection, diode internal welding, BGA welding, etc. The X-ray machine is the X-ray machine can be connected to the computer for image processing, such industrial inspection portable X-ray machine for the factory home appliance repair field provides excellent solutions.

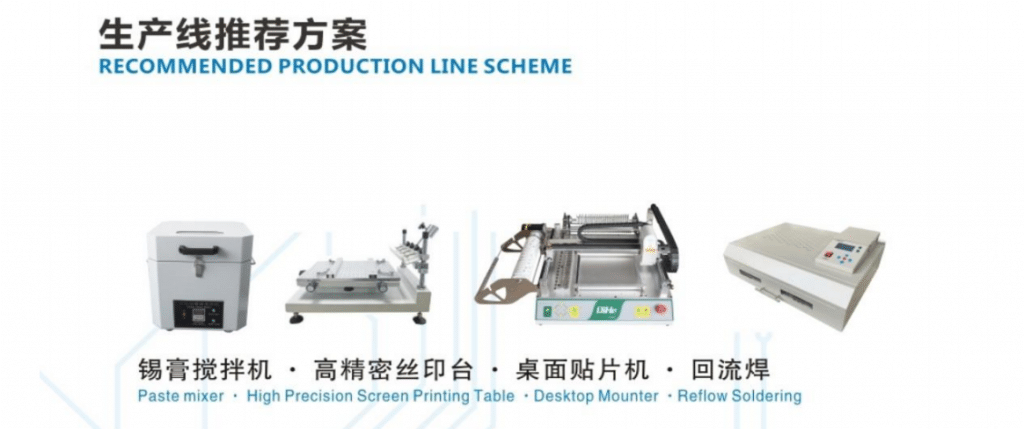

- A small batch SMT production line

Vision mounter (desktop) + high-precision screen printing table (manual) + solder paste mixer (automatic) + small reflow soldering (drawer) = TVM802BX + QH3040 + QH3502 + T962C

- At the end

We QIHE Technology main automatic splicer, solder paste printing machine, docking station, reflow soldering, wave soldering, optical inspection system and other equipment, involving SMT SMD production line program, low price, good quality, can greatly reduce the cost of each SMT SMD production line cost, improve line efficiency. Welcome to call us for consultation!

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

1 Comment

Hi, this weekend is nice in support of me, as this moment i

am reading this impressive educational paragraph here at my residence.!