Author:Lucy Liang

- Highlights

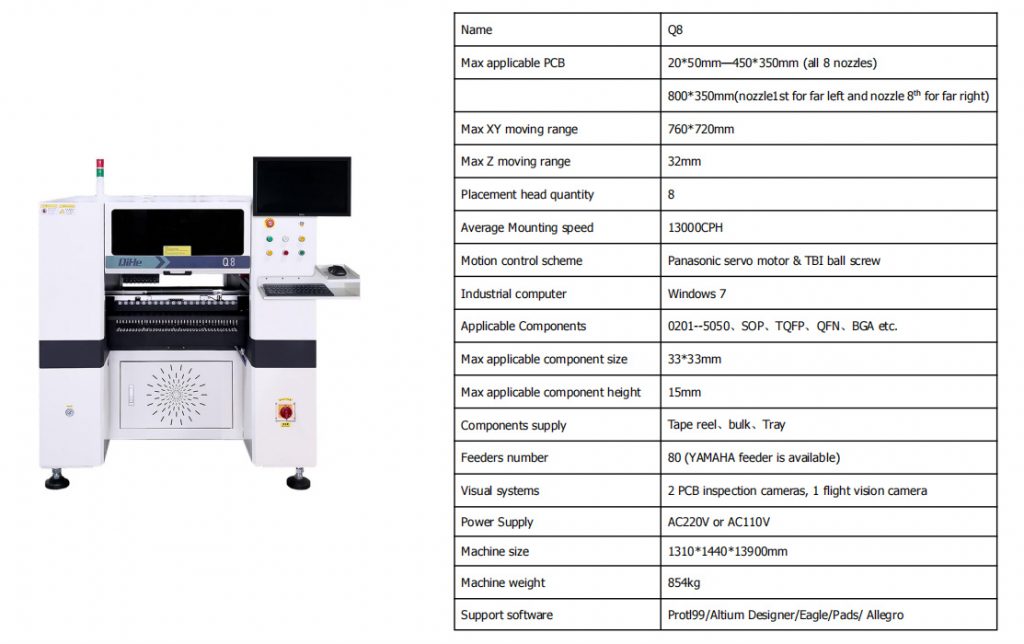

This is a Q8, which is the main automatic placement machine of our Qi He Company.It has 8 mounting heads, uses flying camera, adopts rail transmission mode, and can achieve full automatic production.

- Introduction to feature

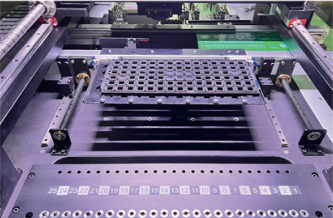

Marble platform:The Q8 SMT machine differs from traditional aluminum plates by using a granite marble base. The marble platform adds weight to the machine, ensuring that the equipment during movement does not shift due to its lightweight. In this way, the accuracy of the machine will be higher, while also enhancing the service life of the screw guide rail, making the machine run more smoothly at high speeds.

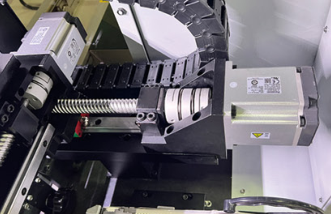

Panasonic servo motor:Servo motors have high motion accuracy and can achieve closed-loop control of position, speed, and torque. Unlike stepper motors, which have the possibility of losing steps, they are more stable in mounting. The servo motor has high speed and good high-speed performance, with a rated speed of up to 3000 revolutions per minute or even faster. The characteristics are low heat generation, low energy consumption, and low noise.

- Software Introduction

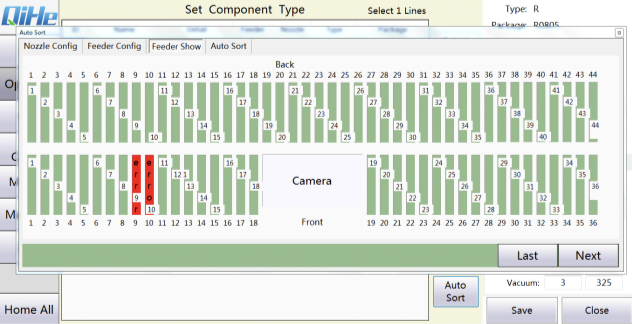

Component library:The intelligent software for SMT machines has a component packaging library that is comparable to imported equipment. The packaging library contains size data, shape features, graphic recognition, nozzle allocation, and Feida matching of various electronic materials. All models with packaging libraries are the identification of intelligent operations and the basis for fast programming.

Intelligent optimization system:There is a reasonable arrangement of material stack order, which can automatically avoid the width of the mounting head. According to the PCB mounting components, automatically arrange the mounting sequence, assign the corresponding material suction nozzle for each component, arrange the material picking sequence and position in a reasonable order and logic, and achieve the most reasonable combination sequence for each round of material picking and mounting.

High-speed recognition of multi-pin large chip:The Qihe Q8 universal SMT machine is equipped with a high pixel and high-precision aerial camera. The template matching function of the cooperating components can quickly identify multi pin large chips. Maximum 176 pin chip.

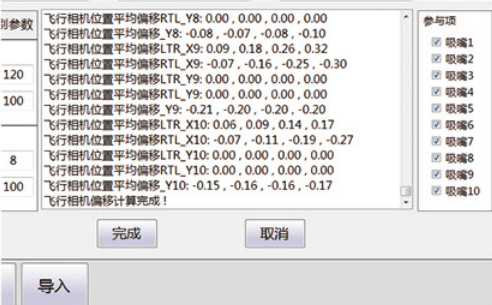

Automatic calibration function:The calibration function can automatically measure the coordinates of the center of the nozzle to the center of the high-definition camera and the center of the down facing camera, and calculate the offset value for correction. Effectively improving accuracy and making operations more convenient.

- Parameters

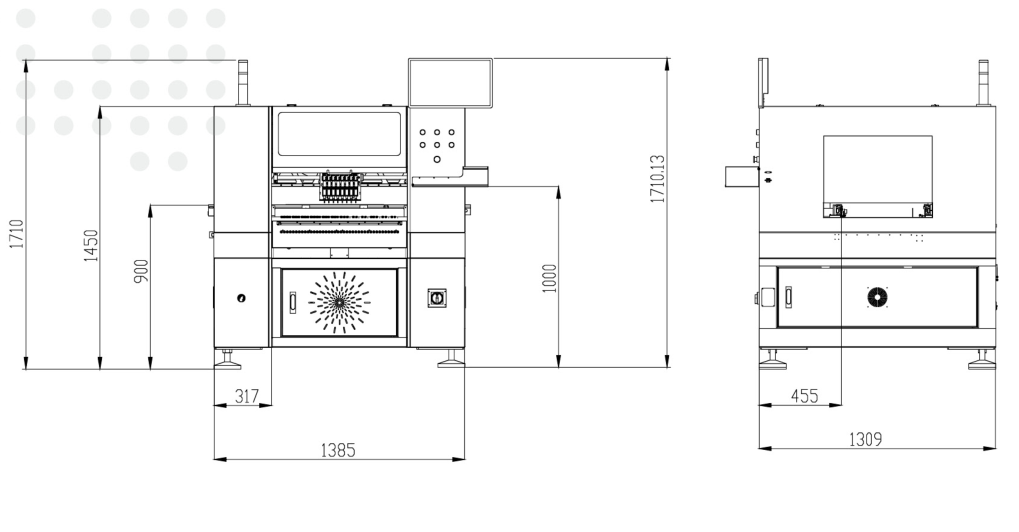

- Appearance dimension drawing

- At the end

Know more about us: https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media: https://www.facebook.com/Qihesmt/

2 Comments

Thanks for breaking this down into easy-to-understand terms.

Thank you for sharing this insightful article! I found the information really useful and thought-provoking. Your writing style is engaging, and it made the topic much easier to understand. Looking forward to reading more of your posts!