Several circuit protection technologies – including metal-oxide varistors (MOVs), TVS diodes, LED protectors, and fuses – are needed to provide overvoltage, overcurrent, and high-temperature circuit protection for commercial LED lighting systems.To protect LEDs from too much current, you can use a current-limiting resistor in series with the LED. The resistor will limit the amount of current flowing through the LED, preventing it from being damaged.Today qihe smt pick and place machine sharing what protects the LED from over supplying of voltage?

Here is not just the LED power supply, each product has its own set of maintenance methods, so how to know the LED power supply? The LED power supply is a type of power supply. It is a device built to supply power to electronic equipment. Called the power supply, it supplies lighting electrical energy and supplies the electrical energy required by all components in the computer. Regarding the maintenance mode, you must know its transition circuit, overshoot circuit, overvoltage circuit, and pass-through circuit.

overcurrent circuit

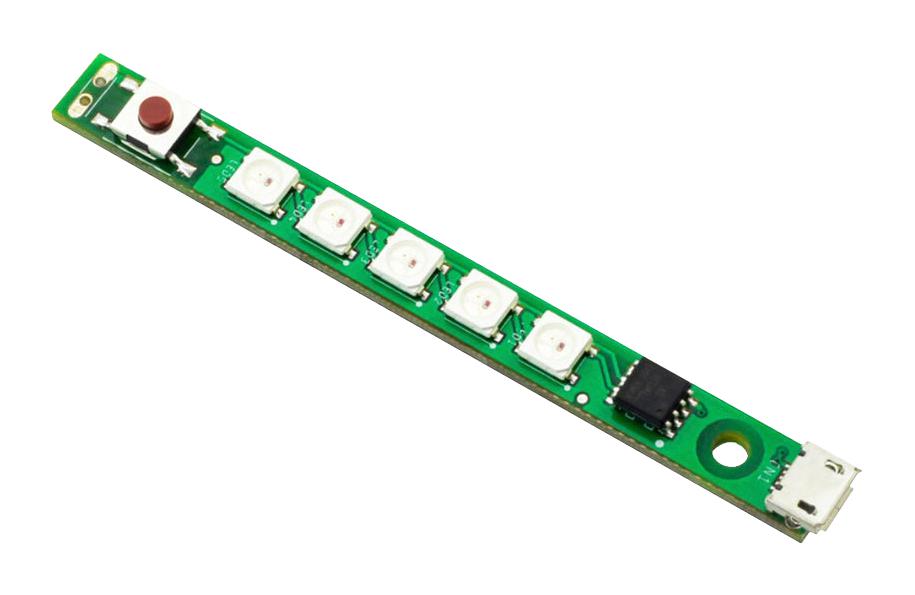

overcurrent circuit: First of all, you must know that when unexpected conditions such as load short circuit, overload, or control circuit failure occur, it will cause excessive current flowing through the switching tube, causing the tube to increase power consumption and generate heat. If there is no overcurrent protection, If installed, the high-power switching tube may be damaged; failure of the regulating circuit may also cause overcurrent damage to the LED. Overcurrent protection usually uses sampling resistors or Hall sensors to check and compare to achieve protection, but they all have the disadvantages of large size and high cost.

overshoot circuit

overshoot circuit: Because the steady-flow switching power supply easily causes current overshoot when starting up and shutting down, loads such as LEDs are not allowed to have ms-level current overshoot, so the impact of a large current in an instant has May damage LED equipment.

overvoltage circuit

overvoltage circuit: If the load of a stabilized current power supply is disconnected, the voltage across the current check resistor drops to zero. Once the given value is not zero, the regulator will cause the output voltage to surge sharply to the maximum value, which will cause the load to be connected It is very risky when there is poor contact. For loads such as LED and semiconductor refrigeration, when overvoltage occurs, the first task is to protect the load, followed by the protection of the switching power tube.

pass-through circuit

pass-through circuit: Half-bridge and full-bridge are common topological structures of switching power supplies, and “pass-through” poses a great threat to them. Pass-through is a phenomenon in which two transistors on the same bridge arm are turned on at the same time at the same time. During the commutation period, the switching power supply is susceptible to interference and causes shoot-through. Excessive shoot-through current will damage the power electronic equipment used for inversion. Once a straight-through phenomenon occurs, it must be detected quickly and the drive must be turned off immediately to prevent the PN junction of the switching device from accumulating excessive heat and burning out.

In order to solve the above problem, we have two protection methods that can be used together. One is to place a bidirectional TVS to protect the instantaneous impulse voltage. In addition to these models, the quality and service of LED power supplies are our primary focus.

Read more: What protects the LED from over supplying of voltage?Best seller SMT Machine :Qihe smt line products

-

Q10 SMT Automatic pick and place machine 10 Heads 100 Slots High Precision and High Efficiency SMT/LED Assembly

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802BX SMT pick and place machine 2heads 46slots desktop pnp mounter deluxe edition

-

QL41 SMT pick and place machine 4heads 8slots LED for 1.2meters led strip pick&place machine

-

Q8 SMT pick and place machine 8heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802AX SMT pick and place machine 2heads 29slots desktop deluxe edition SMT Pick&Place Machine

What is SMT in engineering?

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,and other products.

Small desktop pick and place machine TVM802A,TVM802B,TVM802AX,TVM802BX series suitable for beginners, for hobbiest or low vol usag.

Advanced level 4-head LED strip placement QL41 led machines and with rail universal series TVM925S,TVM926S,pick and place

Fully automatic 6-10-head placement QM61,QM62,QM81,QM10,machines, which are suitable for high volume mass production in factories.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

What is SMT in programming?

Offline Automated Programming vs Inline SMT Programming

Qihe pick and place machine can be programmed directly on the SMT equipment .

Or Coordinates can also be imported csv file through programming software.

Currently supported software such as protel,DXP,Altium Designer,Pads,Candes,proteus,DXP.

Inline SMT programming is a solution to consider for narrow segments of device programming requiring short programming times, with medium to high volume, for just one device type.

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, conveyor,connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.pick and place.pick and place machines,smt machine price,smt machine supplier,suction nozzle,smt assembly,feeder,stock in eu,pcb printer,openpnp feeder,openpnp,pcb pick and place,smt nozzle,smt line,smt meaning,smt process,smt setup,pnp machine,pcb assembly,p&p machine,p&p,pick&place,pick&place machine,pnp,stencil printer,reflow oven,pick and place machine,SMT equipment,smd machine,smt machine,SMT pick and place machine,pick and place machine,smt pick and place.

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

https://www.qhsmt.com/fully-automatic-smt-pick-and-place-machine-line/