A fiducial marker or fiducial is an object placed in the field of view of an imaging system that appears in the image produced, for use as a point of reference or a measure. It may be either something placed into or on the imaging subject, or a mark or set of marks in the reticle of an optical instrument. Today qihe smt pick and place machine sharing why Fiducial Marker Placements on PCBs Necessary?

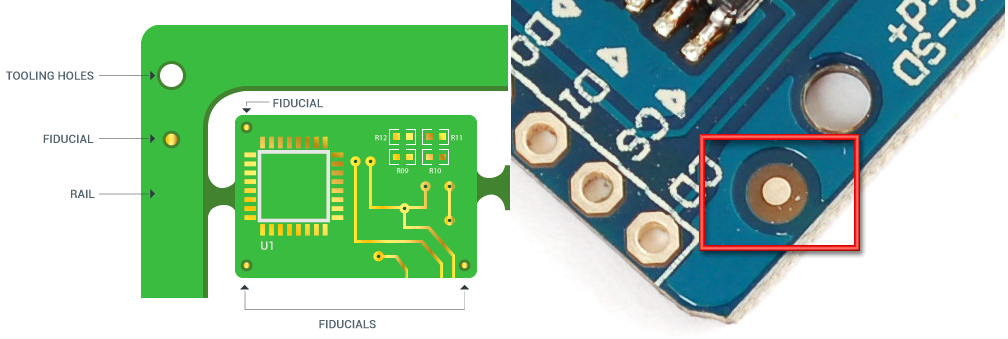

A fiducial mark is typically a circular pad or other shapes of exposed copper that is surrounded by a clearance area. It acts as a reference point for automated machines, such as pick-and-place machines, and also for PCB stencil alignment to ensure that components are accurately placed on the board. During the assembly process, these machines use computer vision systems that scan for the fiducial marks and use their locations to align the PCB and components. Fiducial marks are particularly useful for surface-mount technology components, and it’s advisable to put a mark near the packages with small pitches like BGA, QFN, and QFP.

Types of Fiducial Marks

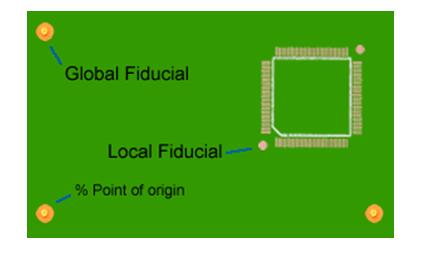

There are two types of fiducial marks commonly found in PCB designs: global fiducial marks and local fiducial marks.

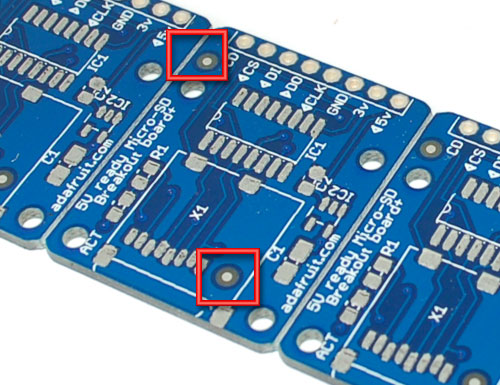

Global fiducial marks, also called panel fiducials, are usually placed near the corners of the PCB or on the panelization rails that hold multiple PCBs together during the assembly process.

Local fiducial marks are typically smaller than global fiducial marks and are placed in areas with high-density components or complex routing. By using local fiducial markers, the assembly machines can precisely locate the footprint of a component and reduce errors in fiducial placement.

Generally, it is recommended to have at least two global fiducial marks, one in the lower left corner of the board and one in the upper right corner of the board, placed on a three-point grid-based system.

Advantages of Using Fiducial Marks for PCB Assembly

While there are other drilled holes or patterns on the PCB, they may not be suitable for alignment due to inconsistencies in size, shape, or position, which can result in inaccuracies during component placement. Furthermore, these holes or patterns may be covered by the solder mask or silkscreen which makes them difficult to be detected. In contrast, fiducial marks are designed with standardized shapes, sizes, and positions to ensure a clear and consistent reference point for alignment.

Guidelines for Using Fiducial Marks in PCB Design

When adding fiducial marks in your PCB designs, there are a few important guidelines you should consider about.

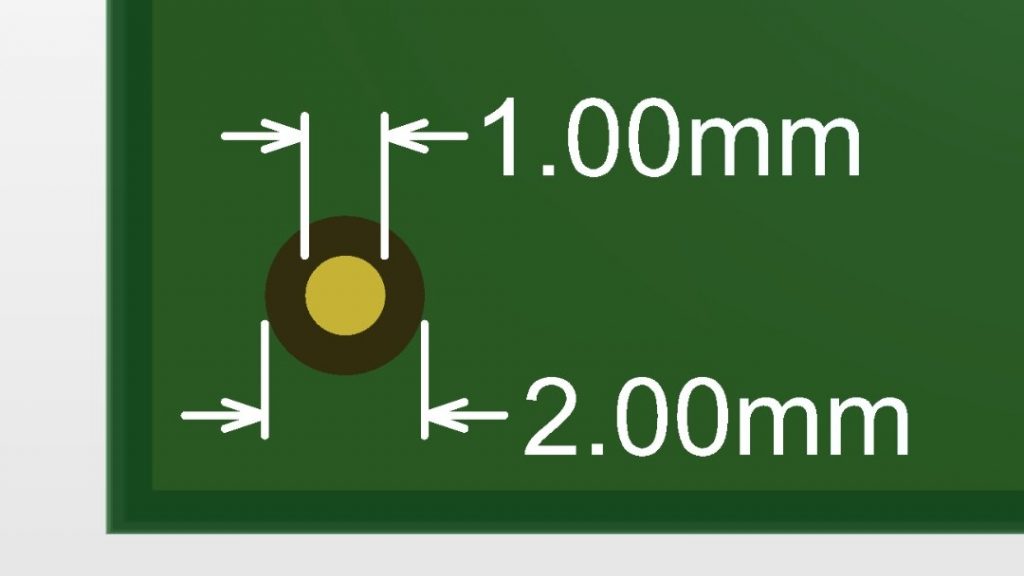

First, the diameter of the fiducial marks should be consistent throughout the PCB design to ensure accurate alignment. The diameter of a fiducial mark typically ranges from 1 to 3 mm.

Second, if your PCB design has components on both sides, it’s important to include fiducial marks on both of them. The absence of fiducial marks on the second side can pose challenges for the automated equipment while flipping the board to assemble components on the opposite side.

Third, the fiducial mark should be free from solder masks and any other coatings. This ensures that the mark is easily visible and distinguishable from the surrounding materials, allowing for accurate and reliable detection by automated assembly equipment.

Read more: Why Fiducial Marker Placements on PCBs so Necessary?Best seller SMT Machine :Qihe smt line products

-

SMT semi-automatic pick and place machine with Dispenser

-

TVM925 SMT pick and place machine 4 head 38 feeders slots assembly of electronic components

-

Q10 SMT Automatic pick and place machine 10 Heads 100 Slots High Precision and High Efficiency SMT/LED Assembly

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802BX SMT pick and place machine 2heads 46slots desktop pnp mounter deluxe edition

-

QL41 SMT pick and place machine 4heads 8slots LED for 1.2meters led strip pick&place machine

What is SMT in engineering?

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,and other products.

Small desktop pick and place machine TVM802A,TVM802B,TVM802AX,TVM802BX series suitable for beginners, for hobbiest or low vol usag.

Advanced level 4-head LED strip placement QL41 led machines and with rail universal series TVM925S,TVM926S,pick and place

Fully automatic 6-10-head placement QM61,QM62,QM81,QM10,machines, which are suitable for high volume mass production in factories.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

What is SMT in programming?

Offline Automated Programming vs Inline SMT Programming

Qihe pick and place machine can be programmed directly on the SMT equipment .

Or Coordinates can also be imported csv file through programming software.

Currently supported software such as protel,DXP,Altium Designer,Pads,Candes,proteus,DXP.

Inline SMT programming is a solution to consider for narrow segments of device programming requiring short programming times, with medium to high volume, for just one device type.

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, conveyor,connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.pick and place.pick and place machines,smt machine price,smt machine supplier,suction nozzle,smt assembly,feeder,stock in eu,pcb printer,openpnp feeder,openpnp,pcb pick and place,smt nozzle,smt line,smt meaning,smt process,smt setup,pnp machine,pcb assembly,p&p machine,p&p,pick&place,pick&place machine,pnp,stencil printer,reflow oven,pick and place machine,SMT equipment,smd machine,smt machine,SMT pick and place machine,pick and place machine,smt pick and place.

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

https://www.qhsmt.com/fully-automatic-smt-pick-and-place-machine-line/