In all simplicity, a termination resistor placed at the end of the transmission line prevents the signal from bouncing back.For standard termination, you would match the termination resistor value with the differential-mode characteristic impedance of the cabling on both ends of the network. This ensures the proper termination of signals traveling in both directions on the bus.Today qihe smt pick and place machine sharing PCB Trace termination techniques: Introduction to Types .

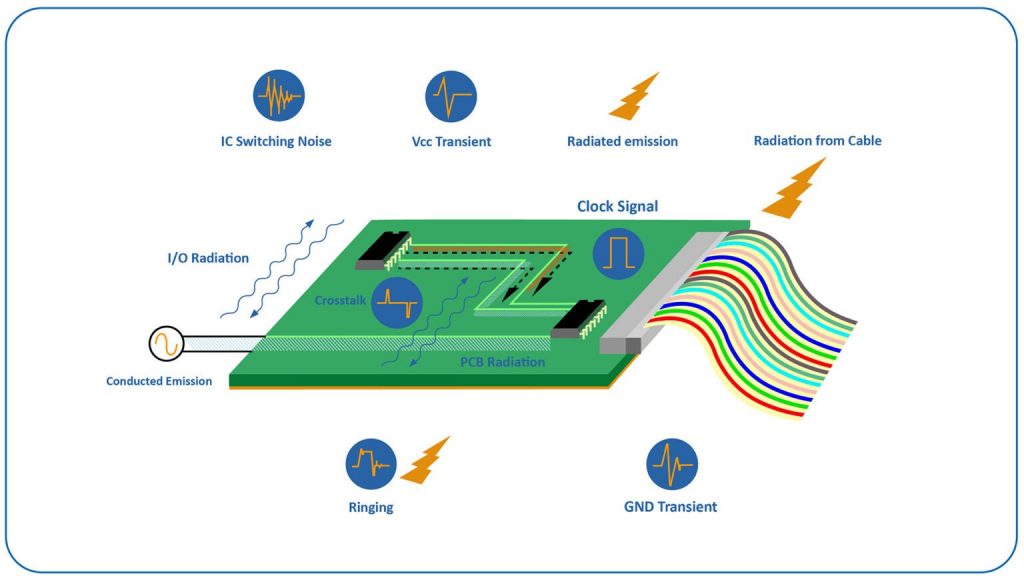

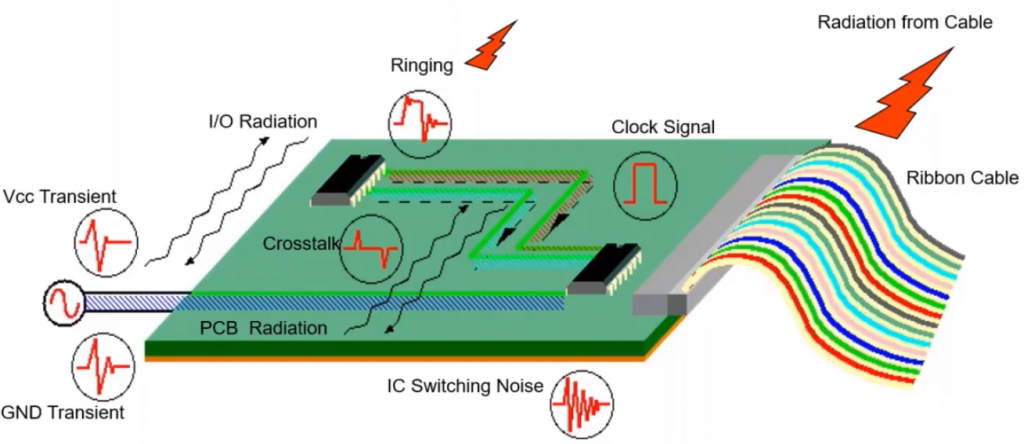

Let’s first talk about why the circuit needs to be terminated? As we all know, if the impedance in the circuit is discontinuous, it will cause signal reflection, causing overshoot, undershoot, ringing and other signal distortions, seriously affecting the signal quality.

Therefore, impedance matching is a very important consideration when designing circuits. Impedance control of our PCB traces is no longer an advanced technology, it is basically a basic ability that every hardware engineer must have.

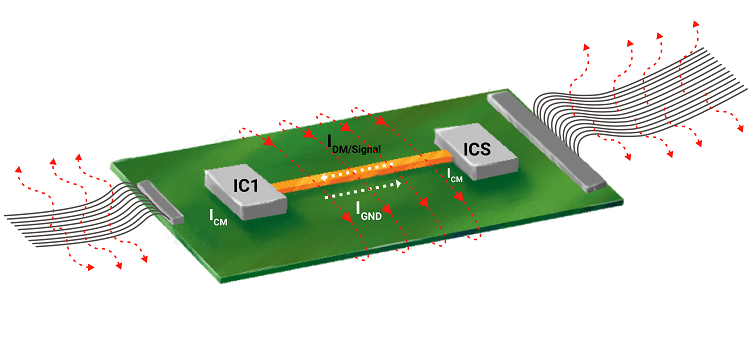

So in a specific circuit, it is not enough to only consider the impedance of the traces. The actual circuit is composed of a sending end, a connection, and a receiving end. What we want to achieve is that the impedance of the entire link is consistent.

However, it is difficult to achieve this in actual circuits. Generally, the output impedance of the transmitting end is relatively small, and the input impedance of the receiving end is high. To handle this contradiction, termination becomes a natural method. Therefore, the essence of termination is still impedance matching, which is the top priority in PCB design.

Common termination methods include the following: series termination, parallel termination, Thevenin termination and RC network termination. The following is a brief introduction to the differences, advantages and disadvantages of several termination methods.

Series termination

his is the easiest and most commonly used termination method for us. The output impedance of the sending end is relatively small, so we directly connect a resistor in series to the circuit so that the total impedance of the output impedance plus the resistor value is equal to the transmission line impedance. This can ensure the continuity of the impedance and reduce signal reflection. Series termination is relatively simple to implement, but its shortcomings are also obvious. Since the resistor is connected in series in the line, it will affect the rise time of the signal, which may cause problems in high-speed circuits. In addition, due to the voltage division of the resistor, the output of the sending end is reduced. The series-terminated resistor should be placed as close as possible to the sending end to play a better role.

Parallel termination

When the input impedance of the receiving end is relatively large, we can consider connecting a resistor in parallel to the ground or power supply at the receiving end. The resistance of the resistor is equal to the characteristic impedance of the trace. Impedance matching is achieved in this way. This method is as simple and easy as series terminals, but the disadvantage is that it consumes DC power. When it is pulled up, it can improve the driving ability, and when it is pulled down, it can improve its ability to absorb current.

Thevenin termination

Thevenin termination uses pull-up resistors and pull-down resistors to form a termination circuit, so that the Thevenin equivalent impedance is equal to the characteristic impedance of the transmission line to achieve impedance matching. The advantage of Thevenin termination is that both pull-up and pull-down resistors can be used to absorb reflections. When there is no signal on the circuit, it can also provide a DC level for the circuit, which is suitable for bus applications. But the disadvantage is also obvious, that is, due to the existence of resistance, there is a DC path between the power supply box and the ground, and the DC power consumption is large.

RC network termination

RC network termination is an upgraded version of parallel termination. Just add a capacitor below the resistor connected in parallel to ground. This can not only reduce reflections like parallel termination, but also isolate DC due to the presence of capacitors, reducing DC power consumption. Of course, the shortcomings are also obvious. The time constant of the RC circuit will affect the rise time of the signal, and must be carefully calculated when using high-speed circuits.

Read more: PCB Trace termination techniques: Introduction to TypesBest seller SMT Machine :Qihe smt line products

-

Q10 SMT Automatic pick and place machine 10 Heads 100 Slots High Precision and High Efficiency SMT/LED Assembly

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802BX SMT pick and place machine 2heads 46slots desktop pnp mounter deluxe edition

-

QL41 SMT pick and place machine 4heads 8slots LED for 1.2meters led strip pick&place machine

-

Q8 SMT pick and place machine 8heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802AX SMT pick and place machine 2heads 29slots desktop deluxe edition SMT Pick&Place Machine

What is SMT in engineering?

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,and other products.

Small desktop pick and place machine TVM802A,TVM802B,TVM802AX,TVM802BX series suitable for beginners, for hobbiest or low vol usag.

Advanced level 4-head LED strip placement QL41 led machines and with rail universal series TVM925S,TVM926S,pick and place

Fully automatic 6-10-head placement QM61,QM62,QM81,QM10,machines, which are suitable for high volume mass production in factories.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

What is SMT in programming?

Offline Automated Programming vs Inline SMT Programming

Qihe pick and place machine can be programmed directly on the SMT equipment .

Or Coordinates can also be imported csv file through programming software.

Currently supported software such as protel,DXP,Altium Designer,Pads,Candes,proteus,DXP.

Inline SMT programming is a solution to consider for narrow segments of device programming requiring short programming times, with medium to high volume, for just one device type.

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, conveyor,connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.pick and place.pick and place machines,smt machine price,smt machine supplier,suction nozzle,smt assembly,feeder,stock in eu,pcb printer,openpnp feeder,openpnp,pcb pick and place,smt nozzle,smt line,smt meaning,smt process,smt setup,pnp machine,pcb assembly,p&p machine,p&p,pick&place,pick&place machine,pnp,stencil printer,reflow oven,pick and place machine,SMT equipment,smd machine,smt machine,SMT pick and place machine,pick and place machine,.

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

https://www.qhsmt.com/fully-automatic-smt-pick-and-place-machine-line/