When electronic components are used to assemble into various electronic devices and are actually used in the market, they need to face various external stress reactions. For example, physical strain caused when an electronic device is dropped, thermal strain caused by the temperature difference between hot and cold, electrical strain when powered on, etc. Due to these external strains, there are cases where electronic components malfunction when the product is used.Today qihe smt pick and place machine sharing how to calculate the life of components.

Therefore, starting from the design stage of each electronic component, the mechanism of external strain and failure is studied and fed back into the reliability design of electronic components. At the same time, by grasping the relationship between the intensity of external strain and the time and probability of failure, an “acceleration model of external strain and failure” is established to evaluate the durability of electronic components in a shorter test time.

As a specific example of the acceleration model, the temperature and voltage acceleration characteristics of the service life of a multilayer ceramic capacitor will be explained. Generally, multilayer ceramic capacitors are composed of electrical insulators (dielectrics) and are highly reliable for continuous energization.

For example, when a control module is installed near a car engine, the temperature of the surrounding environment will increase when it is used.

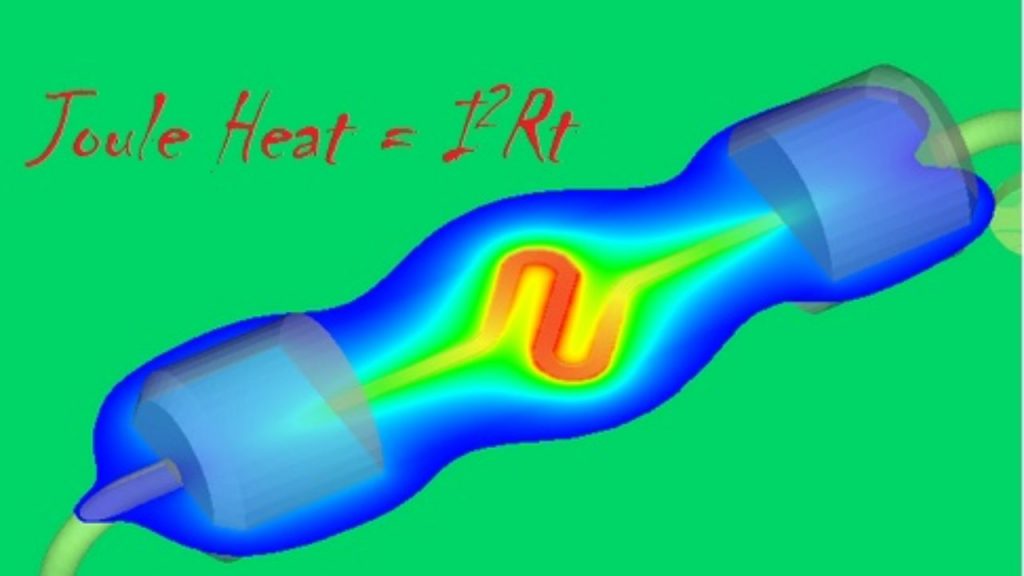

Charge defects at the atomic level, which are extremely small within the ceramic material, move from the + pole (positive pole) to the – pole (negative pole).

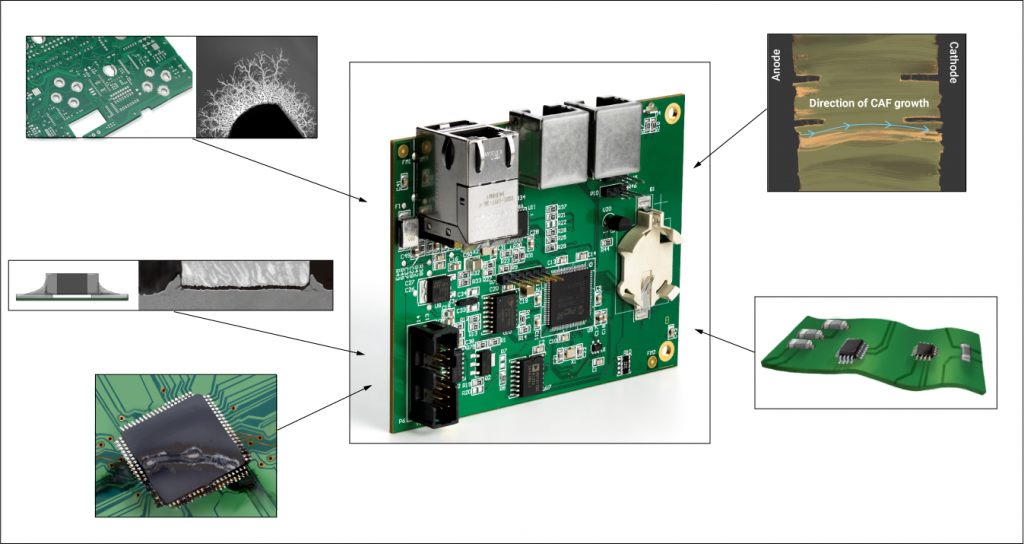

The internal state of the ceramic material used in capacitors

During the firing process of electric ceramics represented by barium titanate, the crystal structure contains a very small amount of atomic-level defects (called oxygen vacancies), which can be slowly moved by an externally applied voltage, and will soon accumulate in the – very close to the pole, which may eventually destroy the ceramic insulation.

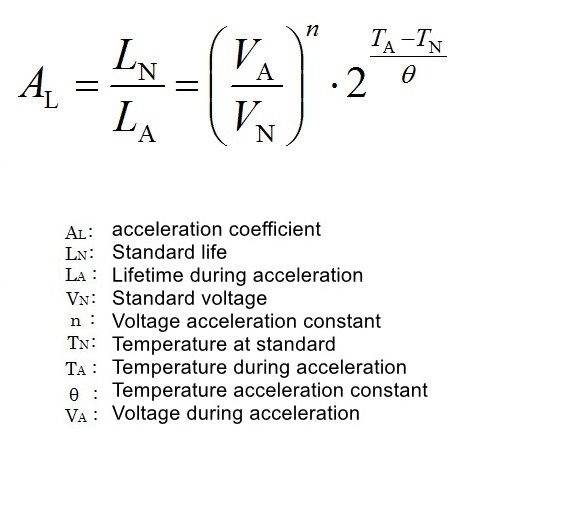

In this way, the durability (life) of a multilayer ceramic capacitor depends on the movement speed and amount of oxygen vacancies in the ceramic material. When establishing the model, the ambient temperature and load voltage when the product is used should be used as parameters. Normally, the acceleration model using the Arrhenius equation can be widely applied, but as a simple calculation method, the following empirical formula can also be used.

Through this relationship, accelerated testing under more stringent conditions (higher temperature, higher voltage) can be used to estimate the durability of the product in the actual use environment.

Here, let us try to compare the accelerated testing of multilayer ceramic capacitors with the preset usage environment of actual products. At this time, the endurance test time in the accelerated test of the capacitor is expressed as LA, and the corresponding number of years in the actual use environment is expressed as LN, and is used in the above formula.

Accelerated testing of multilayer ceramic capacitors and the preset usage environment of actual products

In this way, it can be estimated that the 1000h endurance test conducted under the application environment of 85℃ and 20V is equivalent to 362039h (≈41 years!) under the application environment of 65℃ and 5V. The voltage acceleration constant and temperature acceleration constant used for calculation vary depending on the type and structure of the ceramic material. However, by using the acceleration model, the durability years in a long-term actual use environment can be verified based on test results in a shorter period of time.

The above are examples of multilayer ceramic capacitors. There are many types of commonly used electronic components and envisaged usage environments. Therefore, it is very important to establish a strain-related acceleration model that affects various electronic components.

Read more: How do I find the lifespan of an electrical component?Best seller SMT Machine :Qihe smt line products

What is SMT in programming?

Offline Automated Programming vs Inline SMT Programming

Qihe pick and place machine can be programmed directly on the SMT equipment .

Or Coordinates can also be imported csv file through programming software.

Currently supported software such as protel,DXP,Altium Designer,Pads,Candes,proteus,DXP.

Inline SMT programming is a solution to consider for narrow segments of device programming requiring short programming times, with medium to high volume, for just one device type.

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, conveyor,connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.pick and place

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

https://www.qhsmt.com/fully-automatic-smt-pick-and-place-machine-line/