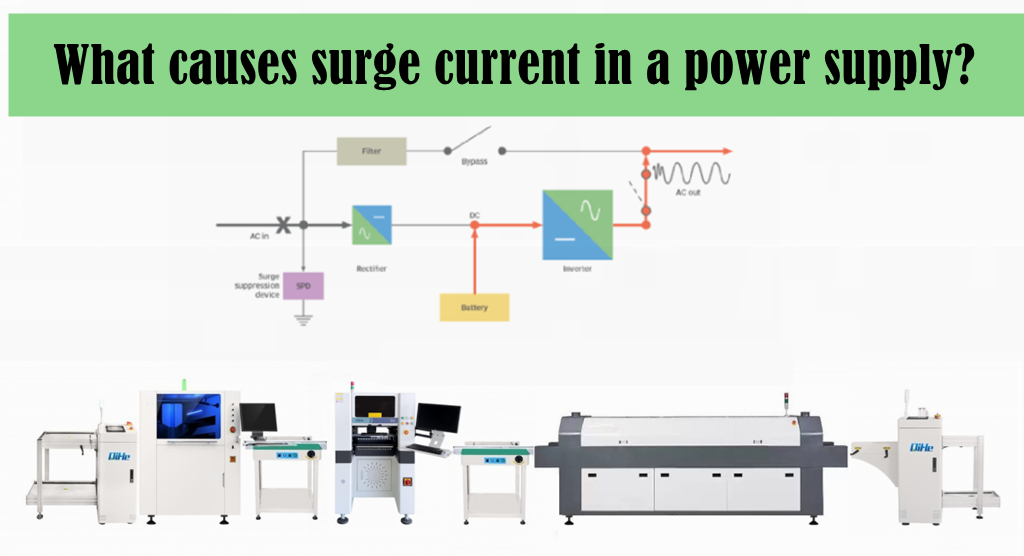

This can happen when you overuse extension cords, plug in too many appliances, or use an appliance above the circuit’s amperage levels. Electrical overloads can lead to power surges as the overwhelmed circuit may receive a massive spike in current due to the excessive power being drawn.Today qihe smt pick and place machine sharing what causes surge current in a power supply .

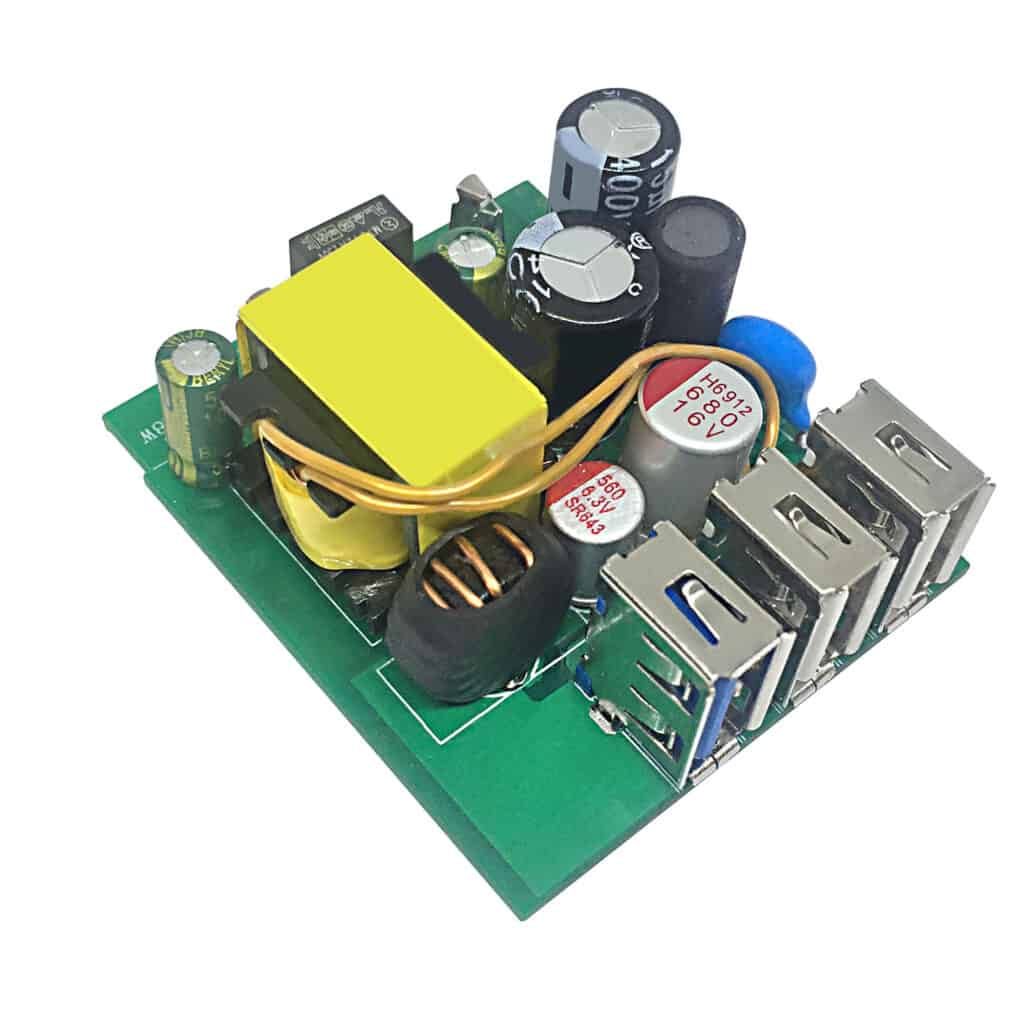

Among various power supplies commonly used in the past and present, switching power supplies are very popular and can generally meet any design requirements. This power supply is very economical, but there are also some problems in industrial design. This is the inherent shortcoming of many switching power supplies (especially high-power switching power supplies): they must draw a large current at the moment of power-on. This surge current may reach 1O times to 100 times the quiescent operating current of the power supply. As a result, at least two problems may arise:

First, if the DC power supply cannot supply sufficient starting current, the switching power supply may enter a locking state and fail to start;

Second, this surge current may cause the input power supply voltage to drop, enough to cause other power equipment using the same input power supply to instantly lose power.

The traditional input surge current limiting method is to connect a negative temperature coefficient thermistor current-limiting resistor (NTC) in series. However, this simple method has many shortcomings: for example, the current-limiting effect of the NTC resistor is greatly affected by the ambient temperature. The effect is only partially achieved during brief input main grid interruptions (on the order of a few hundred milliseconds). The power losses in the NTC resistor reduce the conversion efficiency of the switching power supply… In fact, the two problems raised above can be solved by a “soft start circuit”, which is introduced in detail below.

Causes of surge current in switching power supply

Most of the input circuits of switching power supplies use capacitor filter rectifier circuits. When the incoming power supply is turned on, since the initial voltage on the capacitor is zero, a large surge current will form at the moment when the capacitor is charged. Especially for high-power switching power supplies, which use Larger capacity filter capacitors can increase the surge current to more than 100A. Such a large surge current at the moment when the power is turned on will often cause the input fuse to blow out or the contacts of the closing switch to burn out, causing overcurrent damage to the rectifier bridge; in the worst case, it will also cause the air switch to fail to close. The above phenomena will cause the switching power supply to fail to work properly. For this reason, almost all switching power supplies are equipped with a soft-start circuit to prevent inrush current to ensure the normal and reliable operation of the second-hand robot power supply.

Electrical working principle of soft start circuit

If a “soft start circuit” is used to eliminate the inrush current when the switching power supply is started, the shortcomings of the traditional inrush current limiting method mentioned above can be well avoided. Controlling the start-up of the switching power supply to eliminate inrush current through “soft start” includes two design principles: removing the load at the moment of power-on and limiting the useful current at the same time. If the load is not driven, the current of the switching power supply is generally very small when it is started. In many cases, the starting current may actually be less than the steady-state operating current maintained using this method.

Read more: What causes surge current in a power supply?Best seller SMT Machine :Qihe smt line products

-

SMT semi-automatic pick and place machine with Dispenser

-

TVM925 SMT pick and place machine 4 head 38 feeders slots assembly of electronic components

-

Q10 SMT Automatic pick and place machine 10 Heads 100 Slots High Precision and High Efficiency SMT/LED Assembly

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802BX SMT pick and place machine 2heads 46slots desktop pnp mounter deluxe edition

-

QL41 SMT pick and place machine 4heads 8slots LED for 1.2meters led strip pick&place machine

What is SMT in engineering?

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,and other Smt pick and place machine products.

Small desktop pick and place machine TVM802A,TVM802B,TVM802AX,TVM802BX series suitable for beginners, for hobbiest or low vol usag.

Advanced level 4-head LED strip placement QL41 led machines and with rail universal series Q4,TVM925S,TVM926S,pick and place

Fully automatic 6-10-head placement QM61,QM62,QM81,QM10,machines, which are suitable for high volume mass production in factories.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

What is SMT in programming?

Offline Automated Programming vs Inline SMT Programming

Qihe pick and place machine can be programmed directly on the SMT equipment .

Or Coordinates can also be imported csv file through programming software.

Currently supported software such as protel,DXP,Altium Designer,Pads,Candes,proteus,DXP.

Inline SMT programming is a solution to consider for narrow segments of device programming requiring short programming times, with medium to high volume, for just one device type Smt pick and place machine .

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, conveyor,connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.pick and place

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

https://www.qhsmt.com/fully-automatic-smt-pick-and-place-machine-line/