An electronic component known as an inductor has the ability to store electric energy in the form of magnetic energy. An inductor’s current flows through its terminals when a voltage is applied across them, producing a magnetic field. In turn, this magnetic field induces a current to flow in the opposite direction.Today qihe smt pick and place machine sharing the working principle and function of the inductor.

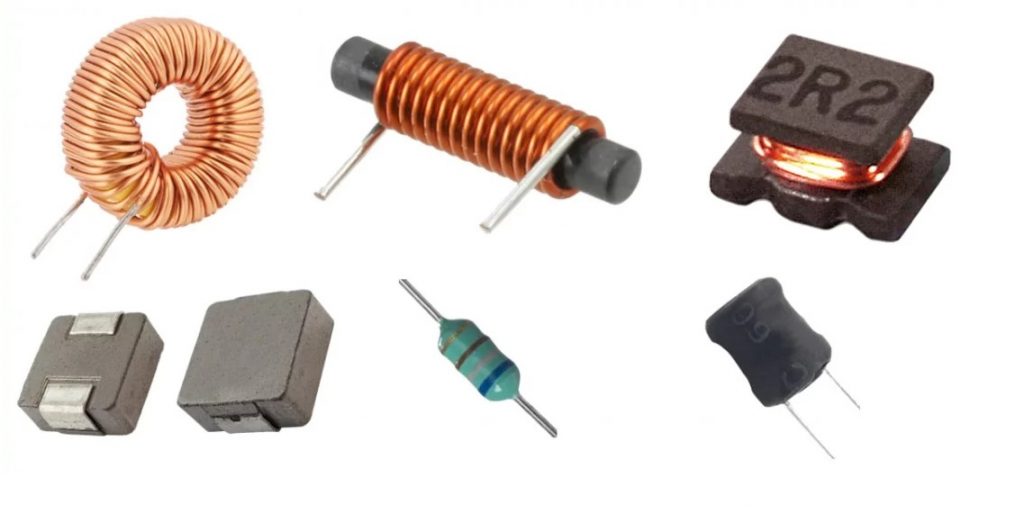

Inductance is the ratio of the magnetic flux in the wire to the current that produces this magnetic flux when an alternating current flows through the wire. When DC current passes through the inductor, only fixed magnetic lines of force appear around it, which do not change with time; however, when AC current passes through the coil, magnetic lines of force that change with time will appear around it. According to the analysis of Faraday’s law of electromagnetic induction – magnetism generates electricity, the changing magnetic field lines will generate an induced electric potential at both ends of the coil. This induced electric potential is equivalent to a “new power supply”.

When a closed loop is formed, this induced potential will produce an induced current. From Lenz’s law, we know that the total amount of magnetic field lines generated by the induced current should try to prevent the change of the magnetic field lines. Changes in magnetic lines of force originate from changes in the external alternating power supply. Therefore, from an objective effect, the inductor coil has the characteristic of preventing current changes in the AC circuit. The inductor coil has characteristics similar to the inertia in mechanics. It is called “self-induction” in electricity. Usually, sparks will occur at the moment when the knife switch is opened or turned on. This self-induction phenomenon causes a lot of problems. Caused by high induced potential.

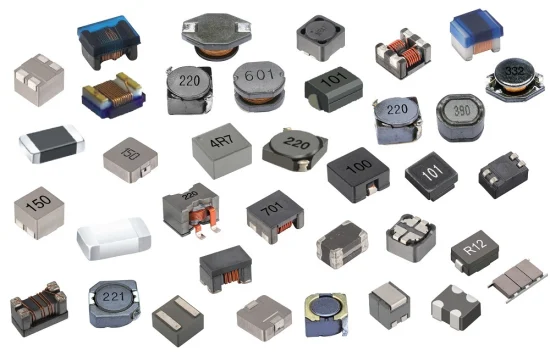

In short, when the inductor coil is connected to the AC power supply, the magnetic lines of force inside the coil will change all the time with the alternating current, causing the coil to produce electromagnetic induction. This electromotive force generated by changes in the current of the coil itself is called “self-induced electromotive force”. It can be seen that the inductance is only a parameter related to the number of turns, size, shape and medium of the coil. It is a measure of the inertia of the inductor coil and has nothing to do with the external current.

Function of the inductor 1 – Current resistance of the inductor coil: The self-induced electromotive force in the inductor coil is always resistant to the current change in the coil. The inductor coil has a blocking effect on the AC current. The magnitude of the blocking effect is called inductive reactance XL, and the unit is ohms. Its relationship with the inductance L and the AC frequency f is XL=2πfL. Inductors can be mainly divided into high-frequency choke coils and low-frequency choke coils.

Function 2 of the inductor – Tuning and frequency selection: The inductor coil and the capacitor are connected in parallel to form an LC tuning circuit. That is, the natural oscillation frequency f0 of the circuit is equal to the frequency f of the non-AC signal, then the inductive reactance and capacitive reactance of the loop are also equal, so the electromagnetic energy oscillates back and forth in the inductor and capacitor, which is the resonance phenomenon of the LC loop. During resonance, the inductive reactance and capacitive reactance of the circuit are equal and opposite. The inductive reactance of the total loop current is the smallest and the current is the largest (referring to the AC signal with f=”f0″). The LC resonant circuit has the function of selecting frequency and can convert a certain An AC signal of frequency f is selected.

Function 3 of inductors – Inductors also have the functions of screening signals, filtering noise, stabilizing current and suppressing electromagnetic wave interference.

Function 4 of the inductor – anti-interference, voice shielding function: In electronic equipment, the magnetic ring and the connecting cable form an inductor (the wire in the cable is wound around the magnetic ring several times in the inductor coil), which is commonly used in electronic circuits. The anti-interference component has a good shielding effect on high-frequency noise, so it is called an absorbing magnetic ring. It is usually made of ferrite material and is also called a ferrite magnetic ring (magnetic ring for short). The magnetic ring has different impedance characteristics at different frequencies. The impedance is very small at low frequencies. When the signal frequency increases, the impedance of the magnetic ring increases sharply.

As we all know, the higher the frequency of the signal, the more it radiates, and most signal lines have no shielding layer. These signal lines become good antennas, receiving various messy high-frequency signals in the surrounding environment, and these signals Superimposed on the transmitted signal, it will even change the transmitted useful signal, seriously interfering with the normal operation of electronic equipment, and reducing the electromagnetic interference (EM) of electronic equipment has already been considered. Under the action of the magnetic ring, even if normal and useful signals pass smoothly, high-frequency interference signals can be well suppressed and the cost is low.

Read more: The working principle and function of the inductorBest seller SMT Machine :Qihe smt line products

-

Q10 SMT Automatic pick and place machine 10 Heads 100 Slots High Precision and High Efficiency SMT/LED Assembly

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802BX SMT pick and place machine 2heads 46slots desktop pnp mounter deluxe edition

-

QL41 SMT pick and place machine 4heads 8slots LED for 1.2meters led strip pick&place machine

-

Q8 SMT pick and place machine 8heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802AX SMT pick and place machine 2heads 29slots desktop deluxe edition SMT Pick&Place Machine

What is SMT in engineering?

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,and other Smt pick and place machine products.

Small desktop pick and place machine TVM802A,TVM802B,TVM802AX,TVM802BX series suitable for beginners, for hobbiest or low vol usag.

Advanced level 4-head LED strip placement QL41 led machines and with rail universal series Q4,TVM925S,TVM926S,pick and place

Fully automatic 6-10-head placement QM61,QM62,QM81,QM10,machines, which are suitable for high volume mass production in factories.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

What is SMT in programming?

Offline Automated Programming vs Inline SMT Programming

Qihe pick and place machine can be programmed directly on the SMT equipment .

Or Coordinates can also be imported csv file through programming software.

Currently supported software such as protel,DXP,Altium Designer,Pads,Candes,proteus,DXP.

Inline SMT programming is a solution to consider for narrow segments of device programming requiring short programming times, with medium to high volume, for just one device type Smt pick and place machine .

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, conveyor,connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.pick and place

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

https://www.qhsmt.com/fully-automatic-smt-pick-and-place-machine-line/