The resistor is an ordinary component, but it has extraordinary ways. There are many parameters for resistors. We usually focus on resistance, accuracy, and power rating. These three indicators only need to be appropriate. It is true that in digital circuits, we do not need to pay attention to too many details. After all, there are only numbers 1 and 0, and we do not care about the minimal impact. But in analog circuits, when we use a precise voltage source, or perform analog-to-digital conversion of a signal, or amplify a weak signal, small changes in resistance will have a big impact. Today qihe smt pick and place machine sharing some resistor parameters you must know in SMT process .When we are fussing over resistors, of course we are dealing with analog signals. Later, we will analyze the impact of each resistor parameter based on analog circuit applications.

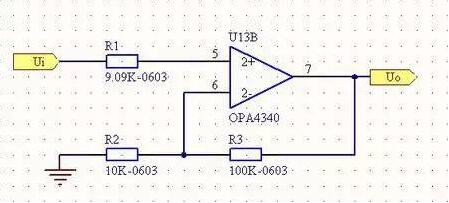

Rated resistance of the resistor – The choice of the rated resistance of the resistor is often fixed by the application, such as limiting the current of an LED light, or sampling a certain current signal. There are basically no other choices for the resistance of the resistor. However, in some cases, there are many choices for resistors, such as amplifying a voltage signal. As shown in the figure, the amplification factor is related to the ratio of R2 and R3, and has nothing to do with the values of R2 and R3.

At this time, there is still a basis for choosing the resistance of the resistor: the larger the resistance of the resistor, the greater the thermal noise, and the worse the performance of the amplifier; the smaller the resistance of the resistor, the greater the working current, and the greater the current noise. The performance of the amplifier will be worse; this is the reason why the resistance of many amplifier circuits is tens of K. Where large resistance values are needed, either a voltage follower or a T-type network is used to avoid this.

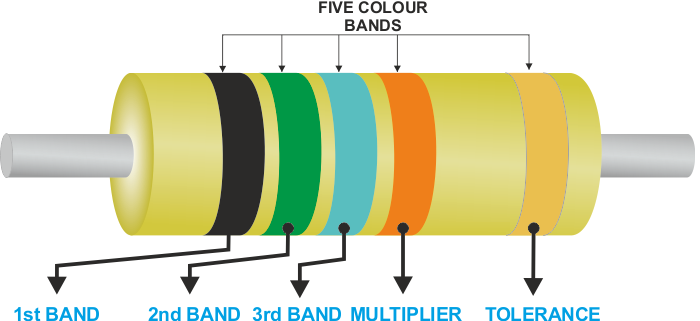

The accuracy of the resistor

the accuracy of the resistor is easy to understand, so I won’t go into details here. The accuracy of resistors is generally 1% and 5%, and the precision is 0.1%, etc. The price of 0.1% is about ten times that of 1%, and the price of 1% is about 1.3 times that of 5%. Generally, the accuracy codes are A=0.05%, B=0.1%, C=0.25%, D=0.5%, F=1%, G=2%, J=5%, K=10%, M=20%.

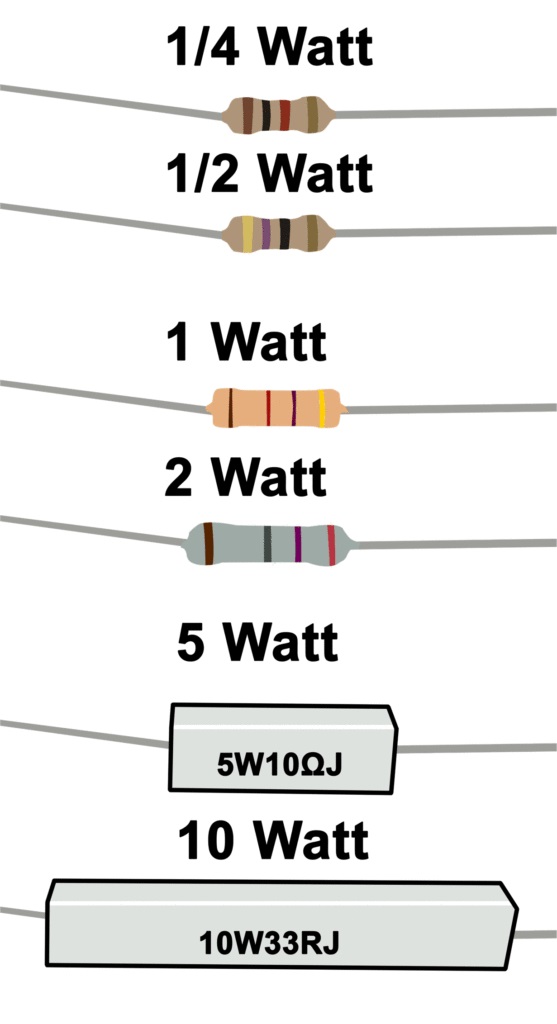

The rated power of the resistor

the power of the resistor is very simple, but it is often easy to use it inappropriately. For example, the rated power of a 2512 chip resistor is 1W. According to the resistor specification, when the temperature exceeds 70 degrees Celsius, the resistor must be derated. How much power can the 2512 chip resistor use? At normal temperature, if the PCB pad does not have special heat dissipation treatment, when the power of the 2512 chip resistor reaches 0.3W, the temperature may exceed 100 or even 120 degrees Celsius.

At a temperature of 125 degrees Celsius, according to the temperature derating curve, the rated power of 2512 needs to be derated to 30%. This situation needs to be paid attention to in any packaged resistor. Do not be superstitious about the nominal power. It is best to confirm the key position again and again to avoid leaving hidden dangers.

The withstand voltage value of the resistor

the withstand voltage value of the resistor is generally rarely mentioned, especially for novices, who often have no idea and think that only capacitors have the withstand voltage value. The voltage that can be applied to both ends of the resistor is determined by the rated power. It must be ensured that the power does not exceed the rated power. The other is the withstand voltage value of the resistor.

Although the power of the resistor does not exceed the rated power, excessive voltage will cause instability of the resistor, creepage between resistor pins and other faults. When using it, a reasonable resistor must be selected according to the voltage used.

The withstand voltage values of some packages include: 0603=50V, 0805=100V, 1206 to 2512=200V, 1/4W plug-in=250V. Moreover, in time applications, the voltage on the resistor should be more than 20% smaller than the rated withstand voltage value, otherwise problems will easily occur over time.

Temperature Coefficient of Resistance

The temperature coefficient of resistance is a parameter that describes the change in resistance with temperature. This is mainly determined by the material of the resistor. Generally, packages of thick film chip resistors above 0603 can achieve 100ppm/℃, which means that when the ambient temperature of the resistor changes by 25 degrees Celsius, the resistance value may change by 0.25%. If it is a 12-bit ADC, a change of 0.25% is 10 LSB.

Therefore, op amps like the AD620 only rely on one resistor to adjust the amplification factor. Many experienced engineers will not use it for convenience. They will use a conventional circuit to adjust the amplification factor through the ratio of two resistors. When the resistors are of the same type When the resistance changes due to temperature, the ratio will not change, and the circuit will be more stable.

For instruments that require higher precision, metal film resistors will be used. It is easy for them to achieve a temperature drift of 10 to 20 ppm, but of course they are more expensive. In short, in precision applications such as instruments, the temperature coefficient is definitely a very important parameter. If the resistance is not accurate, the parameters can be adjusted during calibration. The change of the resistance with the external temperature cannot be controlled.

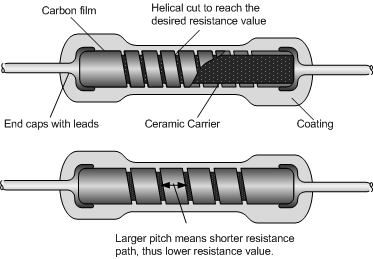

Resistor structure

There are many resistor structures. Here are the applications that can be thought of. The starting resistor of the machine generally uses a resistor to precharge the large-capacity aluminum electrolyte. After the aluminum electrolyte is filled, the relay is closed and the power is turned on.

This kind of resistor needs to be resistant to impact. It is best to use a large wire-wound resistor. The rated power of the resistor is not very important, but the instantaneous power is very high. It is difficult for ordinary resistors to meet the requirements.

For high-voltage applications, such as capacitor discharge resistors, where the actual operating voltage exceeds 500V, it is best to use high-voltage glass glaze resistors instead of ordinary cement resistors.

For peak absorption applications, for example, the two ends of the thyristor module need to be connected in parallel with RC for absorption and dv/dt protection. It is best to implement a non-inductive wire-wound resistor, so that it can have good peak absorption performance and not be easily damaged by impact pick and place machine.

Read more: Some resistor parameters you must know in SMT processBest seller SMT Machine :Qihe smt line products

-

Q10 SMT Automatic pick and place machine 10 Heads 100 Slots High Precision and High Efficiency SMT/LED Assembly

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802BX SMT pick and place machine 2heads 46slots desktop pnp mounter deluxe edition

-

QL41 SMT pick and place machine 4heads 8slots LED for 1.2meters led strip pick&place machine

-

Q8 SMT pick and place machine 8heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802AX SMT pick and place machine 2heads 29slots desktop deluxe edition SMT Pick&Place Machine

What is SMT in engineering?

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,and other products.

Small desktop pick and place machine TVM802A,TVM802B,TVM802AX,TVM802BX series suitable for beginners, for hobbiest or low vol usag.

Advanced level 4-head LED strip placement QL41 led machines and with rail universal series Q4,TVM925S,TVM926S,pick and place

Fully automatic 6-10-head placement pick and place machine QM61,QM62,QM81,QM10,machines, which are suitable for high volume mass production in factories.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

What is SMT in programming?

Offline Automated Programming vs Inline SMT Programming

Qihe pick and place machine can be programmed directly on the SMT equipment .

Or Coordinates can also be imported csv file through programming software.

Currently supported software such as protel,DXP,Altium Designer,Pads,Candes,proteus,DXP.

Inline SMT programming is a solution to consider for narrow segments of device programming requiring short programming times, with medium to high volume, for just one device type pick and place machine.

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, conveyor,connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.pick and place

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

https://www.qhsmt.com/fully-automatic-smt-pick-and-place-machine-line/