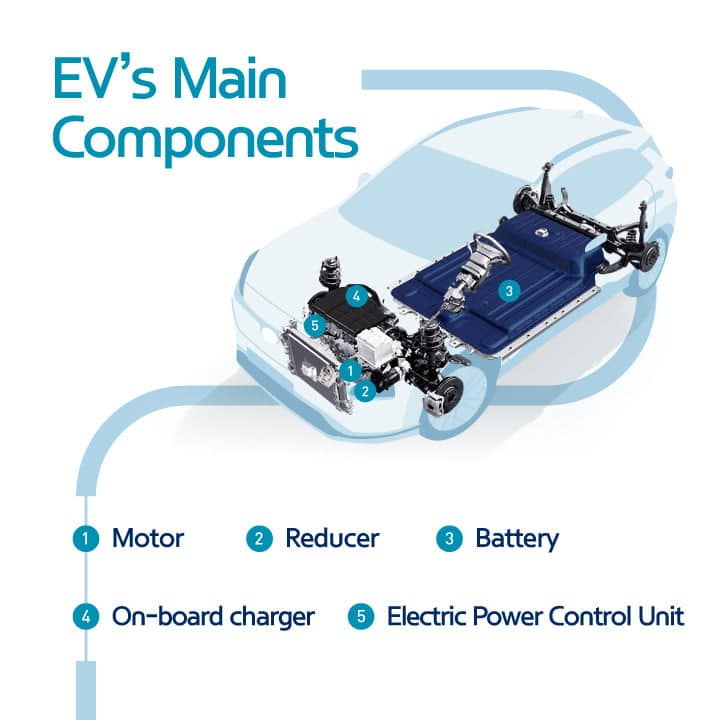

Electric Vehicle (EV), refers to the general term for electric vehicles.

A pure electric vehicle (Battery Electric Vehicle, BEV ) refers to a vehicle powered by batteries or other energy storage devices.Fuel Cell Electric Vehicle (FCEV) refers to a vehicle that uses fuel cells as a power source.Today qihe smt pick and place machine showing EV glossary: All of the electric vehicle jargon you need to know

Drive and travel device

Auxiliary system (Auxiliary System) refers to other on-board systems operated by electricity other than the drive system.

On-board Energy Source refers to the combination of converters and energy storage devices.

Drive system (Propulsion System) refers to the combination of vehicle energy and powertrain.

Power Train refers to the combination of power source and drive train.

The front and rear direction controller (Drive Direction Control) refers to the device that controls the direction of the car through the driver’s operation.

Battery Carrier refers to the device set up to carry the power battery, which is divided into fixed type or mobile type.

Electrical chassis (Electrical Chassis) refers to a group of electrically connected conductive parts whose potential is used as a reference potential.

Power cable refers to the wires that make up the power circuit of the driving motor.

Charging Inlet refers to a device that installs a charging socket or a charging port in the row of the vehicle body.

Electrical devices and components

Circuit Breaker (Circuit Breaker) refers to a device that cuts off the circuit when the circuit is abnormal. Energy Storage refers to devices capable of storing electrical energy, including batteries, supercapacitors, and flywheel batteries.

Live part refers to the conductor or conductive part that is energized during normal use.

Conductive Part (Conductive Part), refers to the part that can make the circuit pass.

Exposed Conductive Part refers to an accessible conductive part.

The main switch refers to the switch used to turn on and off the power battery and control its main circuit.

Insulation Resistance Monitoring System (Insulation Resistance Monitoring System) refers to the insulation resistance detection system between the traction battery and the vehicle chassis.

Maintenance plug (Service Plug), refers to the device that disconnects the circuit when maintaining or replacing the power battery.

Indicators, signaling devices

The battery overheat warning system (Battery Overheat Warning Device) refers to the device that sends out an alarm signal when the temperature of the traction battery exceeds the limit value.

The battery level warning system (Battery Level Warning Device) refers to the device that sends out an alarm signal when the electrolyte level of the traction battery is too low and needs to be replenished.

Residual Capacity Gauge refers to an instrument that displays the remaining power of the traction battery.

Motor Over Revolution Warning Device (Motor Over Revolution Warning Device), refers to the device that sends out an alarm signal when the speed of the motor exceeds the limit value.

Motor Overheat Warning Device (Motor Overheat Warning Device), refers to the device that sends out an alarm signal when the temperature of the motor exceeds the limit value.

Motor Over Current Warning Device (Motor Over Current Warning Device), refers to the device that sends out an alarm signal when the current of the motor exceeds the limit value.

Controller Overheat Warning Device refers to a device that sends out an alarm signal when the temperature of the controller exceeds the limit value.

Insulation Failure Warning refers to a device that sends out an alarm signal when a leakage occurs in the main circuit.

Driving performance

Discharged energy (vehicle) refers to the electric energy released by the energy storage device while the electric vehicle is running.

Regenerated Energy refers to the electrical energy recovered by regenerative braking of a running electric vehicle.

Driving range (Range) refers to the maximum distance that an electric vehicle can travel continuously under certain driving conditions when the power battery is fully charged.

Energy consumption refers to the percentage value of the electricity consumed by the grid and the mileage of the electric vehicle after the specified experimental cycle.

The maximum speed (1 km) (Maximum Speed (1 km)) refers to the highest average speed at which an electric vehicle can travel continuously for a distance of more than 1 km.

The 30min maximum speed (Maximum Thirty-minutes Speed) refers to the maximum average speed at which an electric vehicle can continuously run for more than 30 minutes.

Acceleration Ability refers to the shortest time required for an electric vehicle to reach another speed from a certain speed.

Hill Starting Ability (Hill Starting Ability) refers to the maximum slope at which the electric vehicle can start on a slope and drive up at least 100 m within 1 min.

Power Train Efficiency refers to the ratio of the mechanical energy output from the powertrain to the electrical energy input into the powertrain under pure electric conditions.

Speed Uphill refers to the highest average speed at which an electric vehicle can continue to drive for more than 1km on a given slope.

Regenerative braking (Regeneration Breaking) refers to the braking process that converts a part of kinetic energy into electrical energy and stores it in the energy storage device.

Read more: EV glossary: All of the electric vehicle jargon you need to knowBest seller SMT Machine :Qihe smt line products

-

Q10 SMT Automatic pick and place machine 10 Heads 100 Slots High Precision and High Efficiency SMT/LED Assembly

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802BX SMT pick and place machine 2heads 46slots desktop pnp mounter deluxe edition

-

QL41 SMT pick and place machine 4heads 8slots LED for 1.2meters led strip pick&place machine

-

Q8 SMT pick and place machine 8heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802AX SMT pick and place machine 2heads 29slots desktop deluxe edition SMT Pick&Place Machine

What is SMT in engineering?

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,and other products.

Small desktop pick and place machine TVM802A,TVM802B,TVM802AX,TVM802BX series suitable for beginners, for hobbiest or low vol usag.

Advanced level 4-head LED strip placement QL41 led machines and with rail universal series TVM925S,TVM926S,

Fully automatic 6-10-head placement QM61,QM62,QM81,QM10,machines, which are suitable for high volume mass production in factories.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

What is SMT in programming?

Offline Automated Programming vs Inline SMT Programming

Qihe pick and place machine can be programmed directly on the SMT equipment .

Or Coordinates can also be imported csv file through programming software.

Currently supported software such as protel,DXP,Altium Designer,Pads,Candes,proteus,DXP.

Inline SMT programming is a solution to consider for narrow segments of device programming requiring short programming times, with medium to high volume, for just one device type.

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, conveyor,connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

https://www.qhsmt.com/fully-automatic-smt-pick-and-place-machine-line/