Whether it is a single-chip microcomputer or a microprocessor, their core is a large-scale sequential logic circuit, and the power driving the sequential logic circuit is an accurate and stable clock source-don’t underestimate the attributive “accurate and stable”, in fact The reason why human technology can develop so stably and at a high speed is that it is inseparable from an accurate and stable clock source. Today qihe smt pick and place machine sharing how clock signal is generated in microcontroller.

For example, the crystal oscillator used by the microcontroller is a relatively accurate clock source.Before the crystal oscillator, the oscillation source is generally LC oscillation circuit and other circuits, but they will be affected by the outside world (vibration, temperature, etc.), and their error may reach the kHz level. Its accuracy is also difficult to guarantee under long-time working conditions. The development of radio and digital circuits forced the birth of an accurate and stable clock source, so there was a crystal oscillator.

When a quartz crystal is cut in a certain way and a voltage is applied to it, it will start to vibrate under the action of an external electric field. This property is called “piezoelectricity”. This gives the quartz crystal the ability to resonate with external oscillations. Crystals cut in the same way have the same oscillation frequency, which makes it possible to mass-produce quartz crystals.

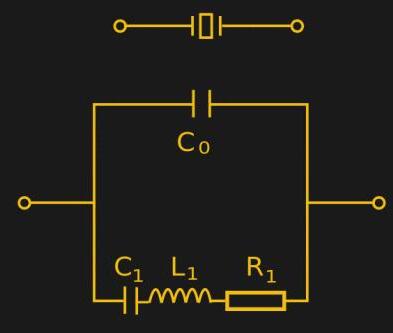

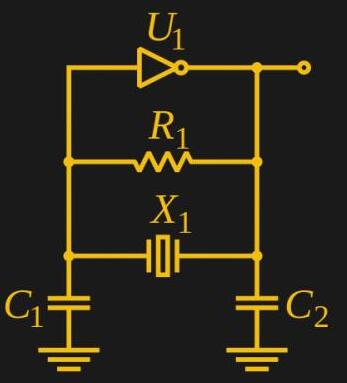

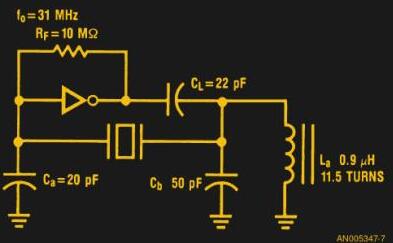

The inside of a practical quartz crystal oscillator typically looks like this: a precision-cut crystal is placed in the middle, sandwiched between two chemically treated metal oxides, and packaged in a strong metal case. This is why the circuit diagram symbol of the crystal oscillator is a crystal sandwiched between two electrodes. The application circuit of a typical quartz crystal oscillator is shown in the figure below:

This circuit is called a Pierce oscillator and uses an inverter to complete the circuit. The two capacitors below generally have the same capacitance value, and their values can slightly affect the oscillation frequency of the entire circuit. Their role is to form a bandpass filter with the quartz crystal, forming a 180-degree phase shift at the resonant frequency of the quartz crystal. This circuit is most commonly found in the clock section of microcontrollers.

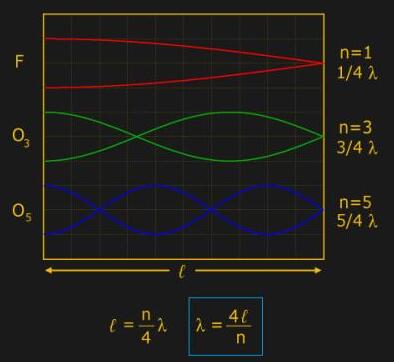

For quartz crystals, the finer they are cut, the higher their resonant frequency – but it is not unlimited. If the cut is too fine, the quartz crystal will be easily broken. And this limit frequency is about 20MHz. How are those crystals above 20MHz made?

In fact, for crystals above 20MHz, they use harmonics in the crystal’s oscillator frequency. We can enhance the odd harmonics of the crystal and take advantage of it. For example, if I want to use a 50MHz crystal, I can make a 10MHz crystal and make its structure enhance the 5 times harmonic (50MHz). For such a crystal, if a pure 50MHz is required, it is necessary to use an external resonant circuit to select the harmonic of this 50MHz.

For something like a clock source, we never mind its high precision, the higher the better. But even an oscillator with a long history like a crystal oscillator is enough for us to study it for a while!

Read more: How clock signal is generated in microcontroller?Best seller SMT Machine :Qihe smt line products

-

Q10 SMT Automatic pick and place machine 10 Heads 100 Slots High Precision and High Efficiency SMT/LED Assembly

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802BX SMT pick and place machine 2heads 46slots desktop pnp mounter deluxe edition

-

QL41 SMT pick and place machine 4heads 8slots LED for 1.2meters led strip pick&place machine

-

Q8 SMT pick and place machine 8heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802AX SMT pick and place machine 2heads 29slots desktop deluxe edition SMT Pick&Place Machine

What is SMT in engineering?

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,and other products.

Small desktop pick and place machine TVM802A,TVM802B,TVM802AX,TVM802BX series suitable for beginners, for hobbiest or low vol usag.

Advanced level 4-head LED strip placement QL41 led machines and with rail universal series TVM925S,TVM926S,

Fully automatic 6-10-head placement QM61,QM62,QM81,QM10,machines, which are suitable for high volume mass production in factories.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

What is SMT in programming?

Offline Automated Programming vs Inline SMT Programming

Qihe pick and place machine can be programmed directly on the SMT equipment .

Or Coordinates can also be imported csv file through programming software.

Currently supported software such as protel,DXP,Altium Designer,Pads,Candes,proteus,DXP.

Inline SMT programming is a solution to consider for narrow segments of device programming requiring short programming times, with medium to high volume, for just one device type.

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, conveyor,connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

https://www.qhsmt.com/fully-automatic-smt-pick-and-place-machine-line/