While the transmission rate of high-speed PCB design and wiring system is steadily accelerating, it also brings some anti-interference vulnerability. This is because the higher the frequency of transmitting information, the higher the sensitivity of the signal, and at the same time their energy is getting weaker and weaker. At this time, the wiring system is more susceptible to interference. Interference is everywhere. Cables and equipment will interfere with other components or be seriously interfered by other sources of interference, such as: computer screens, mobile phones, electric motors, radio relay equipment, data transmission and power cables, etc. In addition, potential eavesdroppers, cybercriminals, and hackers are on the rise, as their interception of UTP cable information transmissions can cause enormous damage and loss. qihe smt pick and place machine sharing you with PCB Manufacturing skills today.

Especially when using high-speed data networks, the time required to intercept large amounts of information is significantly lower than the time required to intercept low-speed data transmissions. The twisted wire pairs in the data twisted pair can rely on their own twisting to resist external interference and crosstalk between the wire pairs at low frequencies, but at high frequencies (especially when the frequency exceeds 250MHz), only rely on Twisted wire pairs can no longer achieve the purpose of anti-interference, and only shielding can resist external interference.

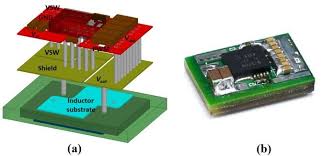

The cable shield acts like a Faraday shield, allowing interference signals to enter the shield but not the conductor. Therefore, data transmission can run without problems. Because shielded cables have lower radiated emissions than unshielded cables, network transmissions are prevented from being intercepted. Shielded networks (shielded cables and components) can significantly reduce the level of electromagnetic energy radiation that enters the surrounding environment and may be intercepted.

Shielding options for different interference fields There are two main types of interference fields: electromagnetic interference and radio frequency interference. Electromagnetic interference (EMI) is primarily low-frequency interference, with motors, fluorescent lights, and power lines being common sources of EMI. Radio frequency interference (RFI) refers to radio frequency interference, mainly high frequency interference. Radio, television broadcast, radar, and other wireless communications are common sources of radio frequency interference. For resisting electromagnetic interference, braided shielding is the most effective because it has a lower critical resistance; for radio frequency interference, foil shielding is the most effective, because braided shielding depends on the change of wavelength, and the gap it produces makes high-frequency signals free Incoming and outgoing conductors; and for high and low frequency mixed interference fields, the combined shielding method of foil layer and braided mesh with broadband coverage function should be used. Generally, the higher the mesh shielding coverage, the better the shielding effect.

Read more: What is PCB Shield ? – PCB Manufacturing skillsBest seller SMT Machine :Qihe smt line products

-

Q10 SMT Automatic pick and place machine 10 Heads 100 Slots High Precision and High Efficiency SMT/LED Assembly

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802BX SMT pick and place machine 2heads 46slots desktop pnp mounter deluxe edition

-

QL41 SMT pick and place machine 4heads 8slots LED for 1.2meters led strip pick&place machine

-

Q8 SMT pick and place machine 8heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802AX SMT pick and place machine 2heads 29slots desktop deluxe edition SMT Pick&Place Machine

What is SMT in engineering?

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,and other products.

Small desktop pick and place machine TVM802A,TVM802B,TVM802AX,TVM802BX series suitable for beginners, for hobbiest or low vol usag.

Advanced level 4-head LED strip placement QL41 led machines and with rail universal series TVM925S,TVM926S,

Fully automatic 6-10-head placement QM61,QM62,QM81,QM10,machines, which are suitable for high volume mass production in factories.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

What is SMT in programming?

Offline Automated Programming vs Inline SMT Programming

Qihe pick and place machine can be programmed directly on the SMT equipment .

Or Coordinates can also be imported csv file through programming software.

Currently supported software such as protel,DXP,Altium Designer,Pads,Candes,proteus,DXP.

Inline SMT programming is a solution to consider for narrow segments of device programming requiring short programming times, with medium to high volume, for just one device type.

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, conveyor,connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

https://www.qhsmt.com/fully-automatic-smt-pick-and-place-machine-line/