The selection of single-chip microcomputer is an important and troublesome thing. If the type is selected properly, the product will be cost-effective and work stably; otherwise, it may cause excessive product cost or affect the normal operation of the product, and may even fail to meet the pre-design requirements at all.Today author from QiHe smt pick and place machine tell you about it with you .

In general, the general selection principles are:

Memory

The capacity of the MCU FLASH is determined according to the size of the program, and the capacity of the FLASH must be greater than the amount of code. For example, if your code size is about 50 KB, it is recommended that you choose a microcontroller with a FLASH capacity of 64 KB or 128 KB.

speed

The operating speed of a single-chip microcomputer first depends on the clock frequency. Generally speaking, for single-chip microcomputers of the same structure, the higher the clock frequency, the faster the speed. If your design requires high speed, then choose a microcontroller that runs faster. For example, in general, most motor control applications use a sampling rate of 100ksps or higher, so when a microcontroller is used for motor control, the clock frequency must be high enough. In short, when selecting a single-chip microcomputer, the clock frequency should be selected according to the needs of the product. Don’t pursue high speed one-sidedly. The higher the clock frequency, the greater the power consumption. In addition, parameters such as the stability and anti-interference of the single-chip microcomputer are basically inversely proportional to the operating speed of the single-chip microcomputer. Therefore, try to find a microcontroller that can run at a very high clock frequency without consuming too much power.

Peripheral requirements

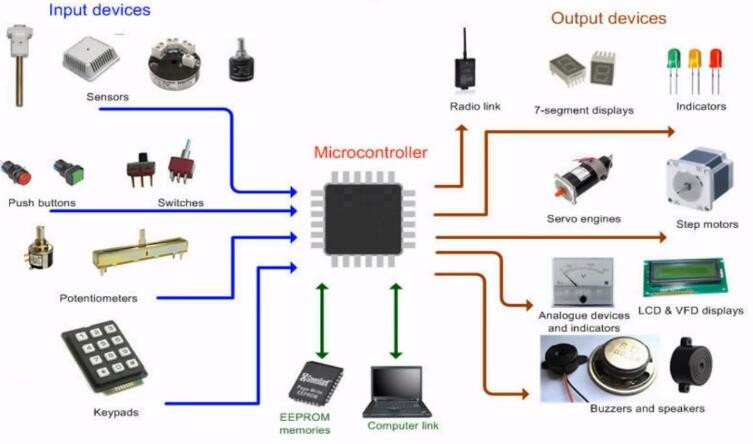

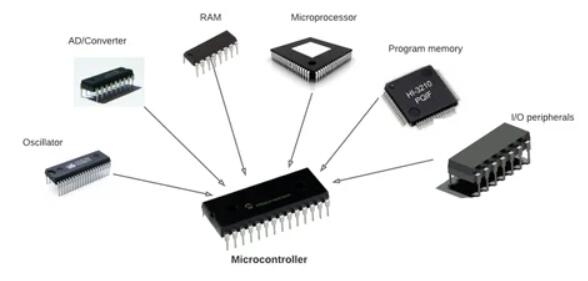

If your design requires peripherals such as ADC, SPI, GPIO, USB, etc., then you need to find a microcontroller that integrates all these peripherals. Because it is obviously more economical to use a single-chip microcomputer with the above-mentioned peripherals than to use an ordinary single-chip microcomputer and a peripheral plus a separate ADC. In addition, the integration of peripherals into the MCU also means lower power consumption, because there are no peripheral circuits that can generate power consumption, and there is no copper plating that can generate power consumption for connecting peripheral circuits, only the MCU itself generates power consumption.

Convenient development tools

This is a very important aspect because development tools can greatly affect the power consumption of the product you are designing. Many companies have developed compilers with code optimization functions, so when you compile the code, the compiler will inform you of the specific compilation information, and you can optimize the code according to the compilation information to reduce power consumption. For example, if your design needs to use peripherals such as ADC, UART, and GPIO, you need to initialize these devices, but the use of UART in the design is conditional (only for displaying results during debugging), and the compiler will prompt you to disable this peripheral to reduce power consumption. It must be said that this intelligent development tool is a boon for developers.

Future requirements and compatibility

When designing a product, the designer needs to consider issues such as the possibility that the product may need to be upgraded in the future. For example, if you need to add some functions to the design, you may need to increase memory, peripherals, etc., and you may also need to increase the operating speed of the microcontroller. Therefore, in the selection of single-chip microcomputers, it is necessary to find a balance between current design requirements and future designs to meet different levels of requirements.

Cost

A good design must not only have perfect functions, but also meet the cost requirements. If the cost cannot be controlled, no matter how good the design is, it will be in vain. Therefore, it is necessary to reduce the cost of the single-chip microcomputer or even the whole product as much as possible.

Working voltage (VCC)

The working voltage of the single-chip microcomputer refers to the voltage that needs to be provided to make it work normally. The higher the operating voltage, the greater the power consumption of the microcontroller. Therefore, in order to reduce product power consumption, it is necessary to reduce the operating voltage as much as possible.

In addition, I also recommend that designers choose the appropriate chip architecture according to specific product requirements. If it is only a simple control application (such as lighting systems, electronic toys, etc.), then there is no need for a chip with a complex architecture like ARM. In addition, for low-power designs, the microcontroller must have a sleep mode, and the use of sleep-mode/low-power modes for interrupt-based operation is a standard industry practice to reduce power consumption.

Read more: Introduction to MicrocontrollersBest seller SMT Machine :Qihe smt line products

-

Q10 SMT Automatic pick and place machine 10 Heads 100 Slots High Precision and High Efficiency SMT/LED Assembly

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802BX SMT pick and place machine 2heads 46slots desktop pnp mounter deluxe edition

-

QL41 SMT pick and place machine 4heads 8slots LED for 1.2meters led strip pick&place machine

-

Q8 SMT pick and place machine 8heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802AX SMT pick and place machine 2heads 29slots desktop deluxe edition SMT Pick&Place Machine

What is SMT in engineering?

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,and other products.

Small desktop pick and place machine TVM802A,TVM802B,TVM802AX,TVM802BX series suitable for beginners, for hobbiest or low vol usag.

Advanced level 4-head LED strip placement QL41 led machines and with rail universal series TVM925S,TVM926S,

Fully automatic 6-10-head placement QM61,QM62,QM81,QM10,machines, which are suitable for high volume mass production in factories.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

What is SMT in programming?

Offline Automated Programming vs Inline SMT Programming

Qihe pick and place machine can be programmed directly on the SMT equipment .

Or Coordinates can also be imported csv file through programming software.

Currently supported software such as protel,DXP,Altium Designer,Pads,Candes,proteus,DXP.

Inline SMT programming is a solution to consider for narrow segments of device programming requiring short programming times, with medium to high volume, for just one device type.

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, conveyor,connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

https://www.qhsmt.com/fully-automatic-smt-pick-and-place-machine-line/