LED’s open the way to new applications and markets in various different fields with a broad spectrum of requirements. Beneath other beneficial characteristics, in general, LED’s provide a high reliability, and a lifetime of more than 50;000 hours can be reached. Poor workmanship in manufacturing and unfavorable operational conditions may reduce the reliability significantly. To avoid failures or to achieve fast resolutions of existing problems a good knowledge of the failure mechanisms and suitable analytical methods is required. Qihe LED machine is going to provide an overview of state of the art techniques in LED-Failure analysis.

The main cause of LED failure

a, Sudden increase in supply voltage.

b. The short circuit of a certain component or printed line or other wires in the circuit forms a partial short circuit of the LED power supply path, which increases the voltage at this place.

c, A certain LED is short-circuited due to its own quality damage, and its original voltage drop is passed on to other LEDs.

d. The temperature in the lamp is too high, which will deteriorate the characteristics of the LED.

e, Water has entered the interior of the lamp, and the water is conductive.

f, The anti-static work was not done well during assembly, so that the inside of the LED has been damaged by static electricity. Although normal voltage and current values are applied, it is very easy to cause damage to the LED.

So, what should we do to protect the LED circuit?

A fuse (tube) is used in the protection circuit

Since the fuse is disposable, has a slow response speed, poor effect, and is troublesome to use, the fuse is not suitable for use in finished LED lamps, because LED lamps are now mainly used in urban glory projects and lighting projects. It requires the LED protection circuit to be very strict: it can immediately start the protection when the normal use current is exceeded, so that the power supply path of the LED is disconnected, so that both the LED and the power supply can be protected, and the power supply can be automatically restored after the entire lamp is normal. Does not affect LED work. The circuit should not be too complicated and the volume should not be too large, and the cost should be low. Therefore, it is very difficult to implement the method of using a fuse.

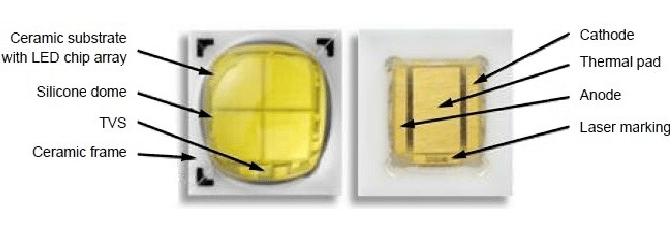

Use Transient Voltage Suppressor Diodes (TVS for short)

A transient voltage suppressor diode is a high-efficiency protection device in the form of a diode. When its two poles are impacted by reverse transient high energy, it can immediately reduce the high resistance between its two poles to low resistance at a speed of 10 minus 12 seconds in a very short time, absorbing up to several thousand watts of surge power , to clamp the voltage between the two poles at a predetermined voltage value, effectively protecting the precision components in the electronic circuit. Transient voltage suppression diodes have the advantages of fast response time, large transient power, low leakage current, good consistency of breakdown voltage deviation, easy control of clamping voltage, no damage limit, and small size. But it is not easy to find a TVS device that meets the required voltage value in actual use. The damage of LED light beads is mainly caused by overheating of the chip due to excessive current. TVS can only detect overvoltage but not overcurrent. It is very difficult to select a suitable voltage protection point, and this kind of device cannot be produced and it is difficult to use it in practice.

Choose resettable fuse

Resettable fuse, also known as polymer positive temperature thermistor PTC, is composed of polymer and conductive particles. After special processing, the conductive particles form a chain-like conductive path in the polymer. When the normal working current passes (or the components are at normal ambient temperature), the PTC self-recovery fuse is in a low-resistance state; The heat generated rapidly expands the polymer, which cuts off the conductive path formed by the conductive particles, and the PTC self-recovery fuse is in a high-resistance state; when the overcurrent (over-temperature state) in the circuit disappears, the polymer cools down and the volume recovers Normal, in which the conductive particles re-form the conductive path, and the PTC resettable fuse is in the initial low-resistance state. In the normal working state, the heat of the self-recovery fuse is very small, and in the abnormal working state, its heat is very high, and the resistance value is very large, which limits the current passing through it, thereby playing a protective role.

In a specific circuit, you can choose: shunt protection and overall protection.

Shunt protection. Generally, LED lights are divided into many series branches. We can add a PTC component in front of each branch for protection respectively. The advantage of this method is high accuracy and good reliability of protection.

Overall protection. A PTC component is added in front of all light beads to protect the whole lamp. The advantage of this method is that it is simple and does not occupy a large volume. For civilian products, the result of this protection in actual use is satisfactory.

Read more: LED Failure Modes and Methods for AnalysisBest seller SMT Machine :Qihe smt line products

-

Q10 SMT Automatic pick and place machine 10 Heads 100 Slots High Precision and High Efficiency SMT/LED Assembly

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802BX SMT pick and place machine 2heads 46slots desktop pnp mounter deluxe edition

-

QL41 SMT pick and place machine 4heads 8slots LED for 1.2meters led strip pick&place machine

-

Q8 SMT pick and place machine 8heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802AX SMT pick and place machine 2heads 29slots desktop deluxe edition SMT Pick&Place Machine

What is SMT in engineering?

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,and other products.

Small desktop pick and place machine TVM802A,TVM802B,TVM802AX,TVM802BX series suitable for beginners, for hobbiest or low vol usag.

Advanced level 4-head LED strip placement QL41 led machines and with rail universal series TVM925S,TVM926S,

Fully automatic 6-10-head placement QM61,QM62,QM81,QM10,machines, which are suitable for high volume mass production in factories.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

What is SMT in programming?

Offline Automated Programming vs Inline SMT Programming

Qihe pick and place machine can be programmed directly on the SMT equipment .

Or Coordinates can also be imported csv file through programming software.

Currently supported software such as protel,DXP,Altium Designer,Pads,Candes,proteus,DXP.

Inline SMT programming is a solution to consider for narrow segments of device programming requiring short programming times, with medium to high volume, for just one device type.

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, conveyor,connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

https://www.qhsmt.com/fully-automatic-smt-pick-and-place-machine-line/