Hi friends,today I will give you an inventory of some application cases on round PCBs “circular circuit boards ” and the models of Qihe pick and place smt machines they use, most videos came from customer sharing.

Qihe’s full series of placement machines can reach 360° mounting angle , only need to edit the angle in the coordinate file of the PCB drawing, or set the angle in the software of the placement machine.

PCB designs such as motor drive systems are critical and require special considerations and techniques to achieve good performance.

Power efficiency, high-speed switching. Frequency, low noise jitter, and compact board design are often considerations that designers must carefully consider when specifying a motor driver.

According to the form of the motor, the circuit board is designed as a circular hollow type, and the compact circuit board design needs to be designed to place corresponding components at various angles.

QM61 producing round CCD fill light board – 2022 flight cam vision machine

QM61 producing 360° round 20w led lamp board – 2020 6 small cam vision machine

Related products

QL41 producing round led board lamp beads chips Led mounter – 2021 small cam vision machine

QL41 camera light source board – 2019 small cam vision machine

Related products

TVM802BX led chip lamp board circle placement – 2020 vision

TVM802BX R/C 0402,0603,0805 circle placement – 2018 vision

Related products

What is a circular circuit board ?

Circular circuit boards are also called “round pcb””circular circuit boards” or “spherical circuit boards”. Circular PCB imposition needs to use stamp holes to connect the boards. Stamp holes are another connection method of the boards, generally in special-shaped boards. Used more. The edges of the two boards are connected by a small plate, and there are many small holes at the connection between the small plate and the two boards, which is easy to break. The diameter of the circular circuit board is generally 0.65mm. There are 5 vias in a row (of course, you can add more according to your needs, which can enhance the stability), and the distance between the two vias (center distance) is 1mm. The distance between the upper and lower rows of via holes is 2mm. In the PCB, only 2D lines need to be used to draw the vias, and 1/3 of the vias enter the board. Then draw a frame between the two boards to cover all the vias. 2D lines need to be set to all layers.

What is SMT in engineering?

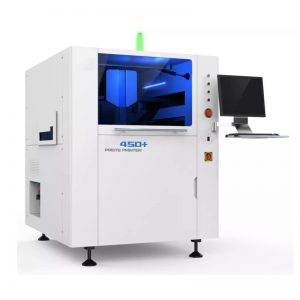

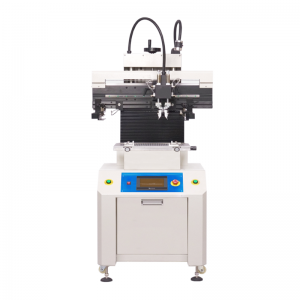

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,and other products.

Small desktop pick and place machine TVM802A,TVM802B,TVM802AX,TVM802BX series suitable for beginners, for hobbiest or low vol usag.

Advanced level 4-head LED strip placement QL41 led machines and with rail universal series TVM925S,TVM926S,

Fully automatic 6-10-head placement QM61,QM62,QM81,QM10,machines, which are suitable for high volume mass production in factories.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

How to choose the right smt pick and place machine?

SMT Pick and place machine can execute virtually all smd material handling operations both cost-efficiently and effectively — With several designs and configurations available in the market, it can be challenging to pick one that suits your operational needs. To help you make the right decision, some factors and features you should look out for when purchasing a pick and place robot.The most important thing is the operating system, then the hardware configuration, the types of components supported, and the speed of operation, the accuracy of placement, and the smt setup cost of the entire smt line .

Qihe smt pick&place machine is a professional operating system independently developed. It has more than ten years of user experience, combined with the algorithm improvement of world-renowned colleges, and the most advanced flying camera and motion system. It is your best choice. The system is friendly for beginners and professionals.

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.