When you want to place some IC chips on the circuit board and want to replace it quickly, you may need to use the IC socket. As users actively shift from plug-in to surface assembly,

The only plug-in components that are preserved are electromechanical components.

Faced with this situation, pcb manufacturers are paying close attention to the launch of new appearance assembled products.

So, what are the two ways to assemble IC sockets on the surface of SMT patches?

There are usually two ways to assemble sockets on the surface of SMT patches:

The first is designed for instrumentation,

It can convert surface mount ICs into socket devices.

When it is desired to use a surface mount package on a full board,

Adapter sockets are a good option.

In this way, the existing plug-in wires can be used to assemble the entire circuit board,

And there is no need to develop a brand-new assembly board that only installs surface assembly equipment.

The second type of socket is designed for surface assembly.

It has roughly the same land pattern as the original package,

Therefore, if planned properly,

The circuit board can be directly equipped with IC,

It is also possible to install interchangeable sockets.

This socket is often used in the early production of general-purpose ROM chips.

QHSMT is an enterprise specializing in the production of SMT equipment, like pick and place machine ,reflow oven,stencil printer ,welcome to send inquiry.

There is no metal connection between the socket and the lead wire of the component,

Instead relying entirely on mechanical touch,

So they are not as strong as soldering.

Such contacts may be corroded in high humidity environments,

The mechanical touch may disconnect during shock or jolt,

Sockets are also expensive,

Therefore, not all components consider using sockets,

Only use it when it makes sense.

E.g,

Sockets used in component testing or burn-in systems must endure repeated plugging and unplugging.

They need to be designed to be more durable.

What is SMT IC sockets

These connectors are designed to provide a compressive interconnect between component leads and a printed circuit board (PCB). Our integrated circuit (IC) sockets are designed to provide a compressive interconnect between component leads and a PCB.

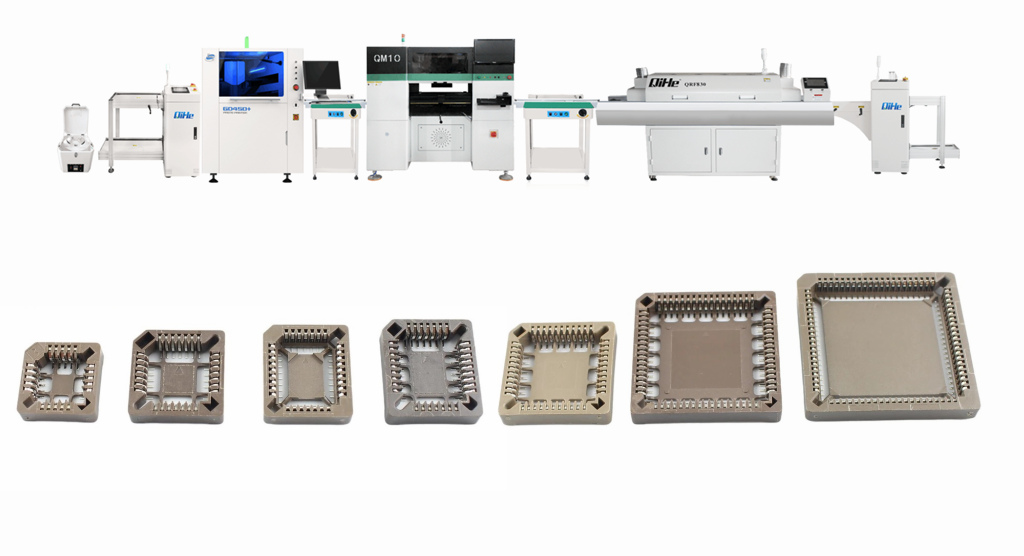

About QIHE SMT pick and place machine

QHSMT is an enterprise specializing in the production of SMT equipment, like pick and place machine ,reflow oven,stencil printer ,smt pick and place machine,pnp,pick&place,pcb assembly,smd chip shooter,pnp machine,chip mounter,smt line,welcome to send inquiry

you can choose a reflow oven to meets your need like qfr630,qrf835,qrf1235

stencil printer model qh3040,qp3250,qfa5060

Also we have different kinds of smt pick and place machine like tvm802a,tvm802b,tvm802ax,tvm802bx,tvm802b plus,tvm925s,tvm926s,ql41,qm61,qm62,qm81,qm10

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

WHAT IS SMT PROCESS?

There are mainly three steps in SMT assembly line process flow: solder paste printing, components placement and reflow soldering.

- Solder Paste Printing

Its function in SMT line process is to print the solder-free paste on the pads of the PCB to prepare for the soldering of the components. The equipment used is a screen printing machine, located at the forefront of the SMT production line. - Components Placement

Its function is to accurately install the surface mount components on the fixed position of the PCB. The equipment used is a placement machine, located behind the screen printing machine in the SMT production line. - Reflow Soldering

Its function in SMT manufacturing line is to melt the solder paste so that the surface mount components and the PCB board are firmly bonded together. The equipment used is a reflow oven, located behind the placement machine in the fully automatic SMT production line.

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.