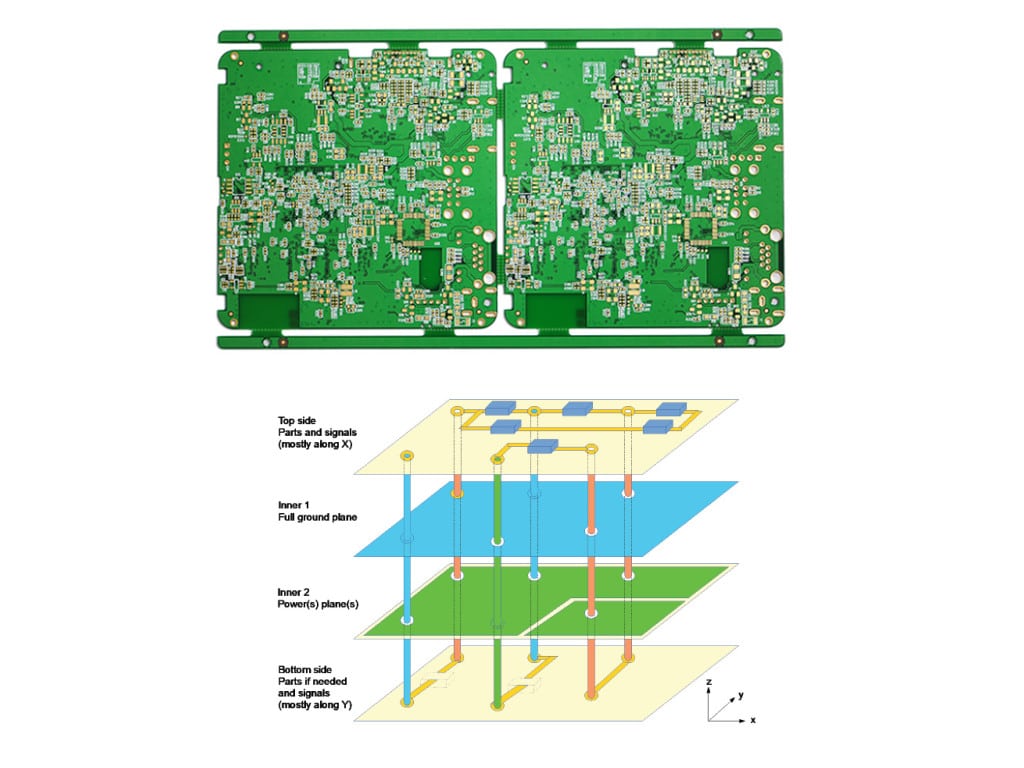

With the development of high-level and high-precision PCB boards, the requirements for alignment accuracy between layers are becoming more and more stringent.

The problem of PCB layer deviation is also becoming more and more serious. There are many reasons for the deviation of the PCB board layer in the circuit board factory.

Now share with us some main influencing factors of layer bias phenomenon.

General definition of PCB layer deviation:

Layer deviation refers to the difference in concentricity between the layers of the PCB board that originally required alignment.

The scope of its requirements is controlled according to the design requirements of different PCB board types.

The smaller the distance from the hole to the copper, the stricter the control to ensure its conduction and overcurrent capabilities.

Commonly used methods to detect layer deviation in the production process:

At present, the method commonly used in the industry is to add a set of concentric circles at the four corners of the production board.

Set the distance between the concentric circles according to the requirements of the production plate deviation,

During the production process, check the concentric offset through X-Ray inspection machine or X-drilling target machine,

To confirm its layer deviation.

Analysis of the causes of PCB layer deviation:

Reasons for inner layer bias

The inner layer is mainly the process of transferring graphics from the film to the inner core board.

Therefore, its layer bias will only occur during the graphics transfer production process,

The main reasons for layer deviation are:

Inconsistent expansion and contraction of the inner film,

Exposure machine alignment offset,

Factors such as improper operation in the process of personnel alignment and exposure.

Reasons for PCB board lamination deviation

The main reasons for the bias of the laminated layer are:

The inconsistent expansion and contraction of the core boards of each layer leads to,

Poor punching positioning hole,

fusion dislocation,

riveting dislocation,

Skateboard and other factors during the pressing process.

QHSMT is an enterprise specializing in the production of SMT equipment, like pick and place machine ,reflow oven,stencil printer ,smt pick and place machine,pnp,pick&place,pcb assembly,smd chip shooter,pnp machine,chip mounter,smt line,welcome to send inquiry

you can choose a reflow oven to meets your need like qfr630,qrf835,qrf1235

stencil printer model qh3040,qp3250,qfa5060

Also we have different kinds of smt pick and place machine like tvm802a,tvm802b,tvm802ax,tvm802bx,tvm802b plus,tvm925s,tvm926s,ql41,qm61,qm62,qm81,qm10

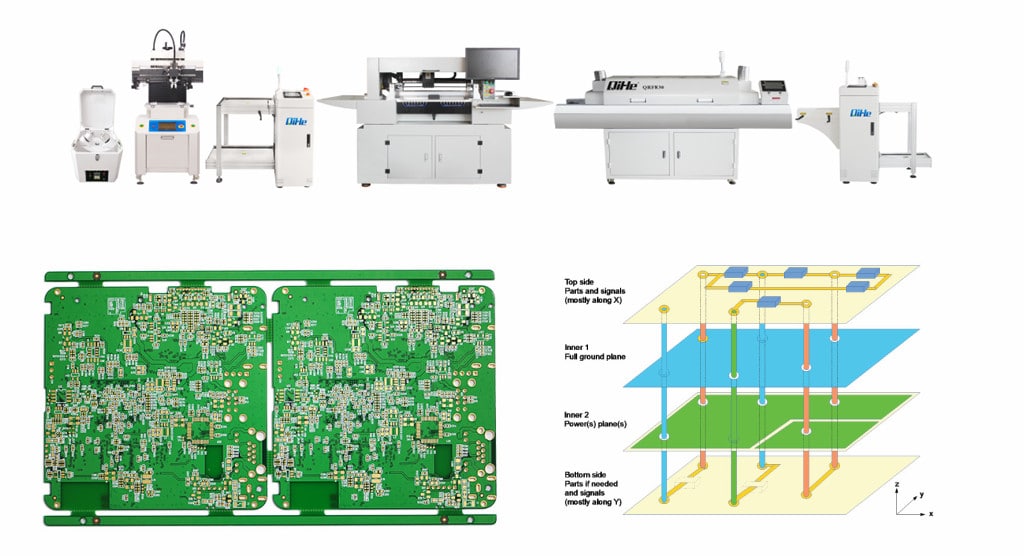

WHAT IS SMT PROCESS?

There are mainly three steps in SMT assembly line process flow: solder paste printing, components placement and reflow soldering.

- Solder Paste Printing

Its function in SMT line process is to print the solder-free paste on the pads of the PCB to prepare for the soldering of the components. The equipment used is a screen printing machine, located at the forefront of the SMT production line. - Components Placement

Its function is to accurately install the surface mount components on the fixed position of the PCB. The equipment used is a placement machine, located behind the screen printing machine in the SMT production line. - Reflow Soldering

Its function in SMT manufacturing line is to melt the solder paste so that the surface mount components and the PCB board are firmly bonded together. The equipment used is a reflow oven, located behind the placement machine in the fully automatic SMT production line.

WHAT IS SMT PROCESS?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

2 Comments

I want to to thank you for this very good read!! I certainly enjoyed every little bit of it. I have got you book-marked to check out new stuff you postÖ

Thank you for your collection

We have new exhibition information updated.

It shows the latest smt products

if you are interested in them

I recommend you take a look at it

Sharing the link

pls check following exhibition news update

LED expo India

https://www.qhsmt.com/2023/05/12/led-expo-mumbai-may-2023-india-qihe-tech-invitation-smt-line/

Lighting show Ningbo

https://www.qhsmt.com/2023/05/10/smt-pick-and-place-machine-lighting-exhibition-albums-and-videos-review/