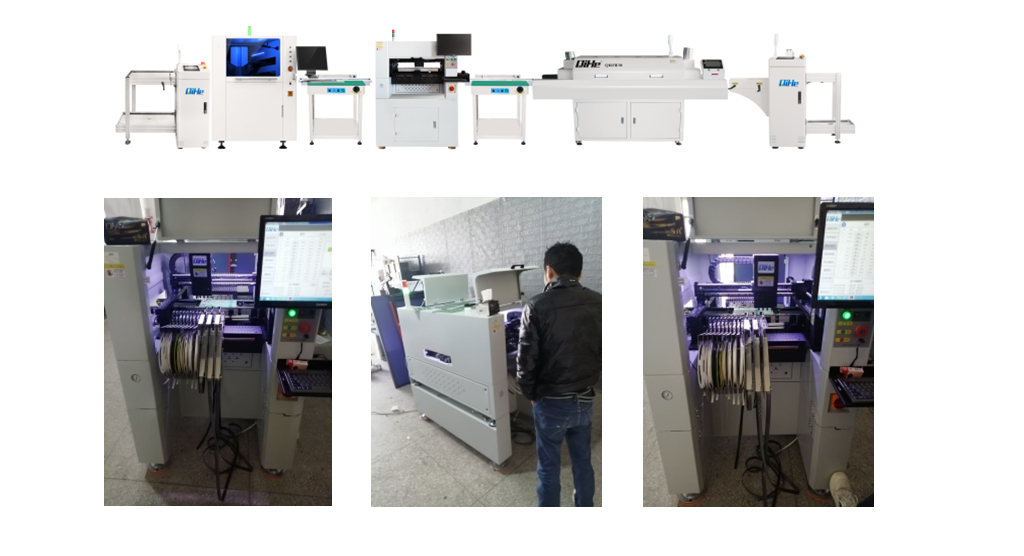

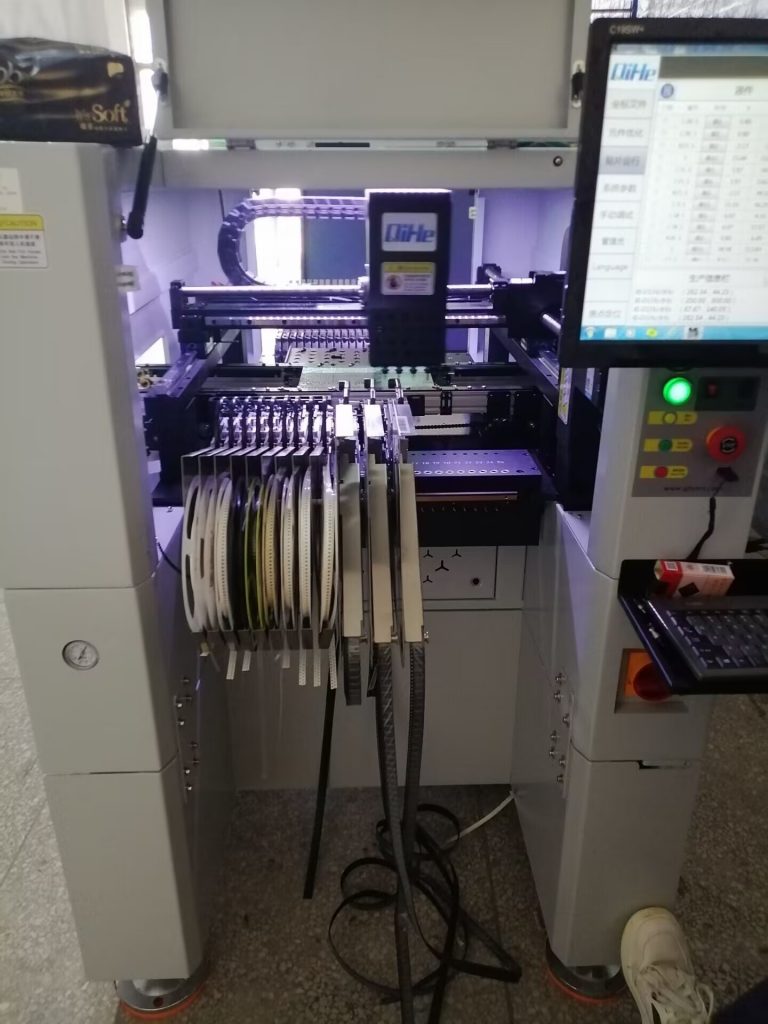

This week, Qihe tech SMT line setup engineers helped customer build a brand new TVM925S smt pick and place machine with customized cabinet for pcb assembly

Configuration includes

stencil printer QH3250→smt conveyor →fully automatic pick and place machine TVM925S →smt conveyor →reflow oven QRF630

This customer initially owned the TVM802 several years ago for R&D project.Now Now with the expansion of production demand, he recently he added a TVM925S PNP automatic production line .

I will share another video of the equipment running in next blog,

Thank you for reading. If you also like this TVM925S smt pnp machine, please feel free to contact sales manager for inquiry

Know more about TVM925S fully automatic pick and place machine

It increased the hardware like the flight camera,the servo driver and motor,the TBI screw rod,and the automatic transfer rail .

Upgraded the software functional such as the component library,the visual surveillance,the safety alerts,the fault previously warning .

Can handling special-shaped components, BGA, 0201 inch package.

X Y axis adopts servo motor, speed of up to 9500 components per hour (CPH).

| Model | TVM925S |

| Max applicable PCB | 50*50mm~350x350mm |

| XY moving range | 410*700mm |

| Z moving range | ±15mm |

| Placement head quantity | 4 |

| Mounting capability | Vision Off: 9500pcs/h Vision On: 6500pcs/h |

| Mounting accuracy | 0.025mm |

| Applicable components | 0201,0402,0603,0805,sop8 etc. |

| Components supply | Tape reel. bulk package(IC)tubes |

| PCB transfer direction | Left→Right |

| Control System | servo motor+TBI Screw Rod |

| Tape width | 8mm. 12mm. 16mm. 24mm |

| Feeders loading ability | 50 slots (YAMAHA Feeder is available) |

| Machine dimension | L1200xW1440xH920mm |

| Visual camera | 1 PCB inspection camera , 1 Flying camera |

| Visual camera(down) | Automatic identify the mark point |

| Visual camera(up) | Automatic adjust the offset |

| Vacuum pump quality | External air pump |

| Power supply | AC220V/AC110V |

| Average working Power | 360W |

| Gross weight | 271KG |

| Packing size | 1.35CBM |

SMT pcb assembly

What is SMT used for?

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,and other products.

QHSMT is an enterprise specializing in the production of SMT equipment, like pick and place machine ,reflow oven,stencil printer ,smt pick and place machine,pnp,pick&place,pcb assembly,smd chip shooter,pnp machine,chip mounter,smt line,welcome to send inquiry

you can choose a reflow oven to meets your need like qfr630,qrf835,qrf1235

stencil printer model qh3040,qp3250,qfa5060

Also we have different kinds of smt pick and place machine like

Small desktop pick and place machine TVM802A,TVM802B,TVM802AX,TVM802BX series suitable for beginners, for hobbiest or low vol usag.

Advanced level 4-head LED strip placement QL41 led machines and with rail universal series TVM925S,TVM926S,

Fully automatic 6-10-head placement QM61,QM62,QM81,QM10,machines, which are suitable for high volume mass production in factories.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

WHAT IS SMT PROCESS?

There are mainly three steps in SMT assembly line process flow: solder paste printing, components placement and reflow soldering.

- Solder Paste Printing

Its function in SMT line process is to print the solder-free paste on the pads of the PCB to prepare for the soldering of the components. The equipment used is a screen printing machine, located at the forefront of the SMT production line. - Components Placement

Its function is to accurately install the surface mount components on the fixed position of the PCB. The equipment used is a placement machine, located behind the screen printing machine in the SMT production line. - Reflow Soldering

Its function in SMT manufacturing line is to melt the solder paste so that the surface mount components and the PCB board are firmly bonded together. The equipment used is a reflow oven, located behind the placement machine in the fully automatic SMT production line.

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.