If you have many packages of components in bulk and don’t want to spend a lot of time to manually arrange the plates.Do you have any good plan?

Today’s customer case may give you some inspiration.

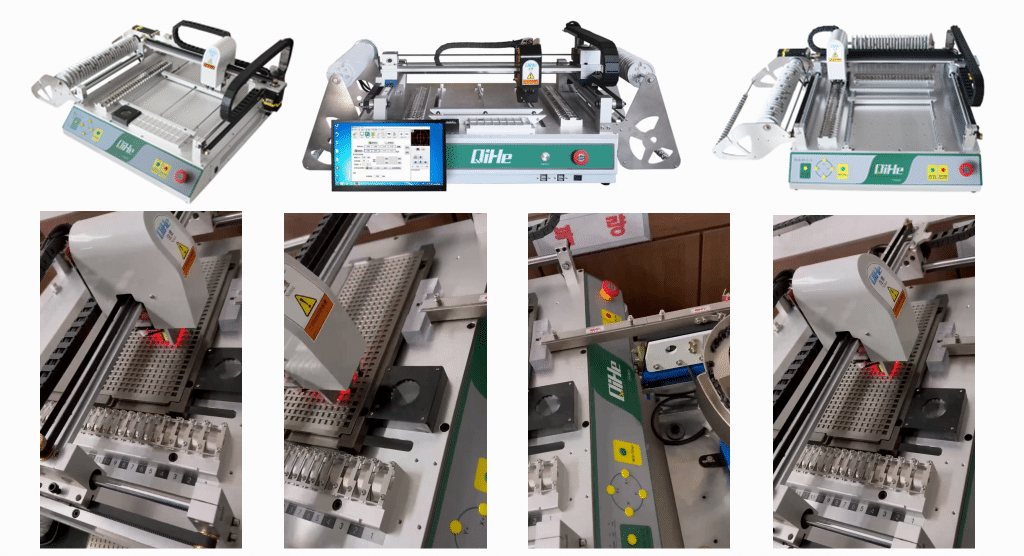

TVM802A desktop pick&place machine assembly with smd vibrating disc.

Adjust the direction of the bulk components through the vibrating disc plate.

Then at the end of vibrating disc feeding,

It is worth mentioning here that the customer used rubber components to make a vibrating plate positioner. At the same time, it separated the direct contact between the vibrating plate and the placement machine, reduced resonance, and has a shock absorption function. This design is very smart. And it’s practical.

Then use the TVM802A placement head,which provide the vacuum suction of the nozzle to pick up the components.

According to the position set by the puzzle board set in the TVM802A pnp software.place it in the material tray. After placed all the components,then arrange the plastic packaging.

Learn more about TVM802A desktop pick&place machine and its series

TVM802A SMT pick and place machine (desktop pnp mounter). There are 29 slots(8mm=25,12mm=3,12mm=1),2 placement heads.

Can handling smallest package size:0402 inch and up to largest size:TQFP100.The external dimensions of TVM802AX pick&place machine are 875mm*640mm*310mm.Standard edition is mainly composed of working head, dual vision system, operation platform, patented feeding rack, main controller system,stepper motor drive system(Flexible-S acceleration),internal vacumm pump, etc. Voltage AC220V or AC110V, power 150W.

what equipments suitable for combining with TVM802A PNP

QHSMT is an enterprise specializing in the production of SMT equipment, like pick and place machine ,reflow oven,stencil printer ,smt pick and place machine,pnp,pick&place,pcb assembly,smd chip shooter,pnp machine,chip mounter,smt line,welcome to send inquiry

you can choose a reflow oven to meets your need like qfr630,qrf835,qrf1235

stencil printer model qh3040,qp3250,qfa5060

Also we have different kinds of smt pick and place machine like tvm802a,tvm802b,tvm802ax,tvm802bx,tvm802b plus,tvm925s,tvm926s,ql41,qm61,qm62,qm81,qm10

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.

WHAT IS SMT PROCESS?

There are mainly three steps in SMT assembly line process flow: solder paste printing, components placement and reflow soldering.

- Solder Paste Printing

Its function in SMT line process is to print the solder-free paste on the pads of the PCB to prepare for the soldering of the components. The equipment used is a screen printing machine, located at the forefront of the SMT production line. - Components Placement

Its function is to accurately install the surface mount components on the fixed position of the PCB. The equipment used is a placement machine, located behind the screen printing machine in the SMT production line. - Reflow Soldering

Its function in SMT manufacturing line is to melt the solder paste so that the surface mount components and the PCB board are firmly bonded together. The equipment used is a reflow oven, located behind the placement machine in the fully automatic SMT production line.

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.