Today author from QiHe smt pick and place machine smt equipment manufacturers sharing you with Problems that are prone to occur in the process of PCB plate making

When we design on PCB design software,

Often due to the seemingly connected parts (electrical performance) on the plane but actually not connected,

So when we start plate making according to the design document,

Order of operations is very important.

Today we go through the following three tricks,

Focus on solving the problems that are prone to occur in the process of PCB plate making.

A making a physical frame

Making a closed physical frame on the original board is a constraint effect on the layout and wiring of later components.

After a reasonable physical frame setting,

The soldering of components one by one and the accuracy of wiring can be more standardized.

But pay special attention to,

Some boards or corners with curved edges,

The physical border should also be set in an arc shape,

The first precaution is to prevent sharp corners from scratching workers,

The second stress relief effect ensures safety during transport.

B. Introduction of components and networks

It should be easy to draw components and nets into the drawn border,

But there is often a problem here,

Be sure to carefully solve the errors one by one according to the prompts,

Otherwise, it will take more effort later on.

The problems here are generally the following:

The packaging method of the component cannot be found,

component network issues,

There are unused components or pins,

Control hints that these problems can be solved quickly.

C. Layout normalization of components

(1) Placement order

Experienced installers will first place components with a fixed orientation related to the structure,

Such as power sockets, indicator lights, switches, connectors and the like.

Then it is locked by software,

Make sure that the components with fixed orientation are moved or affected when other components are placed later.

complex board,

We can divide according to the placement order,

Do it several times.

(2) Pay attention to the influence of layout on heat dissipation

Component layout should also pay special attention to heat dissipation.

Regarding high-power circuits,

Those heating elements such as power tubes and transformers should be placed as far as possible in a scattered layout.

for heat release,

Don’t concentrate in one place,

Also don’t put the high capacitance too close to avoid premature aging of the electrolyte.

Through the above three points, I hope to help the engineers of PCB production.

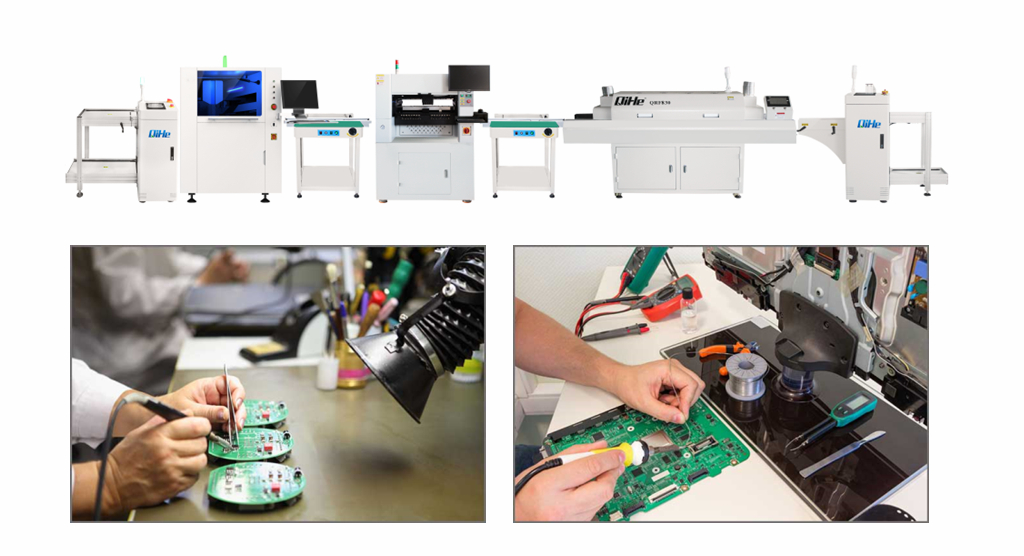

QHSMT is an enterprise specializing in the production of SMT equipment, like pick and place machine ,reflow oven,stencil printer ,welcome to send inquiry.

smt equipment manufacturers

QHSMT is an enterprise specializing in the production of SMT equipment, like pick and place machine ,reflow oven,stencil printer ,smt pick and place machine,pnp,pick&place,pcb assembly,smd chip shooter,pnp machine,chip mounter,smt line,welcome to send inquiry

you can choose a reflow oven to meets your need like qfr630,qrf835,qrf1235

stencil printer model qh3040,qp3250,qfa5060

Also we have different kinds of smt pick and place machine like tvm802a,tvm802b,tvm802ax,tvm802bx,tvm925s,tvm926s,ql41,qm61,qm62,qm81,qm10

-

Professional PCB external pumping type inflatable vacuum packaging machine, moisture-proof and anti-oxidation, guarding the quality of circuit boards

-

Professional PCB external vacuum packaging machine , moisture-proof and anti-oxidation, protecting the quality of circuit boards

-

High – Precision Offline PCBA Cleaner QH-800: Remove Stubborn Flux Residue Completely

-

Low cost cost-effective SMD component point counters

-

High precision solder paste dispensing machine robot QHDJ331R solder paste dispensing machine Automatic dispensing machine for PCBA processing

-

Small Intelligent Wire Stripping Machine QR-220

-

Automatic Soldering Machine Four axis One Rotated head One platform SMT Assembly

-

QH902N SMD component counting machine Reel Counter

-

AOI800 Vision system Automated Optical Inspection AOI machine

What is SMT used for?

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,and other products.

Small desktop pick and place machine TVM802A,TVM802B,TVM802AX,TVM802BX series suitable for beginners, for hobbiest or low vol usag.

Advanced level 4-head LED strip placement QL41 led machines and with rail universal series TVM925S,TVM926S,

Fully automatic 6-10-head placement QM61,QM62,QM81,QM10,machines, which are suitable for high volume mass production in factories.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

WHAT IS SMT PROCESS?

There are mainly three steps in SMT assembly line process flow: solder paste printing, components placement and reflow soldering.

- Solder Paste Printing

Its function in SMT line process is to print the solder-free paste on the pads of the PCB to prepare for the soldering of the components. The equipment used is a screen printing machine, located at the forefront of the SMT production line. - Components Placement

Its function is to accurately install the surface mount components on the fixed position of the PCB. The equipment used is a placement machine, located behind the screen printing machine in the SMT production line. - Reflow Soldering

Its function in SMT manufacturing line is to melt the solder paste so that the surface mount components and the PCB board are firmly bonded together. The equipment used is a reflow oven, located behind the placement machine in the fully automatic SMT production line.