The problem of copper foil conductive circuit breakage is usually caused by the circuit board being damaged by external force,This leads to disconnection of the conductive copper foil.This failure usually renders the circuit unable to conduct electricity.Today author from qihe smt pick and place machine sharing you with some tips about how to deal with the problems encountered when soldering the circuit board?

When correcting this board problem, the

Please use a knife to scrape off the insulating varnish on the copper conductive copper foil at both ends of the breakpoint.

Pull a few thin copper wires out of the copper wire,

Twist them together and tin them once.

Then solder the wires to the conductive copper foil,

Finally cut off the remaining wires.

The problem of pad falling is usually due to repeated soldering to a certain point during maintenance,

cause the pad to disconnect at the solder joint,

This then leads to problems with direct soldering.

After stripping the pads,

First use a knife to scrape off the insulating varnish on the copper foil at the breakpoint,

Pull several thin copper wires from the copper wire, twist them together,

Then use the tin plate again.

Then cut one end and solder it on the conductive copper foil,

The other end is wrapped around the component pin,

Then solder.

Finally, cut off the remaining wires.

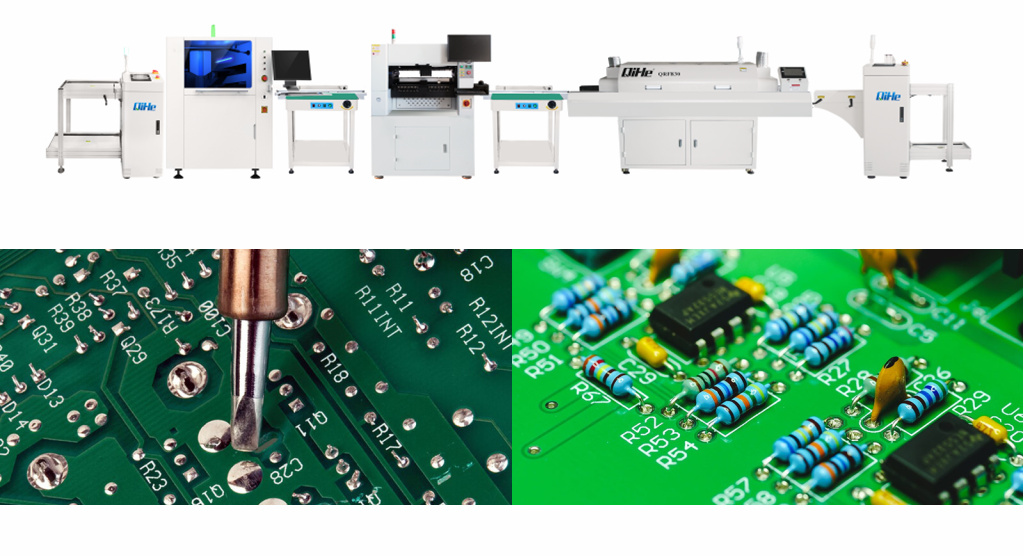

QHSMT is an enterprise specializing in the production of SMT equipment, like pick and place machine ,reflow oven,stencil printer ,welcome to send inquiry.

Desoldering issues lead to bad contacts and sparks,

The circuit board is burnt and charred,

This mainly occurs in areas of higher voltage.

Circuit boards are inherently non-conductive.

However, after the circuit is ignited due to poor contact or other reasons,

Sparks can burn circuit boards.

Cemented carbide can conduct electricity under high pressure,

Therefore, the high voltage fluctuation is not enough,

This then leads to failure of electronic equipment.

When dealing with this issue,

Please use a knife to clean the burnt area first,

Then connect the components with wires,

Brush a layer of insulating paint on each welding point,

Or use insulating paper to block each solder joint.

At the same time, we must rule out the cause of the spark.

If there is some inappropriate content or suggestion .I hope you can leave a reply to tell me and communicate with each other.

you can choose a reflow oven to meets your need like qfr630,qrf835,qrf1235

stencil printer model qh3040,qp3250,qfa5060

Also we have different kinds of smt pick and place machine like tvm802a,tvm802b,tvm802ax,tvm802bx,tvm925s,tvm926s,ql41,qm61,qm62,qm81,qm10

-

Automatic Screen Printing Machine RSE High Efficiency high Power Printing PCB

-

R5 Automatic Screen Printing Machine 2024 new listing SMD Solder Paste Printing

-

Q10 SMT Automatic pick and place machine 10 Heads 100 Slots High Precision and High Efficiency SMT/LED Assembly

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

QP5060 automatic solder paste printer stencil printer machine screen printer machine

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

RF8835LS up8/down8 Zones Reflow Oven solder welding

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.

WHAT IS SMT PROCESS?

There are mainly three steps in SMT assembly line process flow: solder paste printing, components placement and reflow soldering.

- Solder Paste Printing

Its function in SMT line process is to print the solder-free paste on the pads of the PCB to prepare for the soldering of the components. The equipment used is a screen printing machine, located at the forefront of the SMT production line.

- Components Placement

Its function is to accurately install the surface mount components on the fixed position of the PCB. The equipment used is a placement machine, located behind the screen printing machine in the SMT production line.

- Reflow Soldering

Its function in SMT manufacturing line is to melt the solder paste so that the surface mount components and the PCB board are firmly bonded together. The equipment used is a reflow oven, located behind the placement machine in the fully automatic SMT production line.