There is a good way to distinguish the advantages and disadvantages of PCB circuit boards before your SMT process. qihe smt pick and place machine will sharing you some tips today .

With the rapid development of mobile phone, electronics, communication industries, etc., it also promotes the continuous growth and rapid growth of PCB circuit board industry, people’s requirements for the number of layers, weight, precision, material, color, reliability, etc. Come higher.

However, due to the fierce price competition in the market, the cost of PCB board materials is also in a rising trend. In order to enhance the competitiveness of the center, more and more manufacturers are monopolizing the market at low prices. However, these ultra-low-cost backsides are obtained by reducing material costs and process manufacturing costs, but the devices are generally prone to cracks (cracks), easy scratches, (or scratches), and their precision, performance and other general factors are not qualified. , which seriously affects the solderability and reliability of the product used.

Facing all kinds of PCB circuit boards on the market, Baineng.com can distinguish the quality of PCB circuit boards from two aspects; the first method is to judge from the appearance, and the other is from the quality standard requirements of the PCB board itself. discriminate.

How to judge the quality of PCB circuit board

Top of the list: Distinguish the quality of the circuit board from the appearance

In general, the appearance of the PCB circuit board can be analyzed and judged through three aspects;

a. Standard rules for size and thickness. The thickness of the circuit board is different from that of the standard circuit board, and customers can measure and check according to the thickness and specifications of their own products.

b. Light and color. The external circuit boards are covered with ink, and the circuit boards can have an insulating effect. If the color of the board is not bright and there is less ink, the insulation board itself is not good.

c. The appearance of the weld. The circuit board has many parts. If the welding is not good, the parts are easy to fall, which will seriously affect the welding quality of the circuit board. It is very important to have a good appearance, careful identification, and a strong interface.

Second: high-quality circuit boards need to meet the following requirements

a. It is required that the phone should be easy to use in the future when the components are installed, that is, the electrical connection should meet the requirements;

b. The line width, line thickness and line spacing of the line meet the requirements to avoid line heating, open circuit, and short circuit;

c. The copper skin is not easy to fall off under high temperature;

d. The appearance of copper is not easy to oxidize, which affects the speed of the device, and it will be broken soon after oxidation;

e. No additional electromagnetic radiation;

f. The shape is not deformed, so as to avoid the deformation of the shell after the installation and the dislocation of the screw holes. Now they are all mechanized devices, and the hole position of the circuit board and the deformation error between the circuit and the plan should be within the permitted range;

g. High temperature, high humidity and special environment resistance should also be considered;

h. The mechanical properties of the surface should meet the requirements of the device;

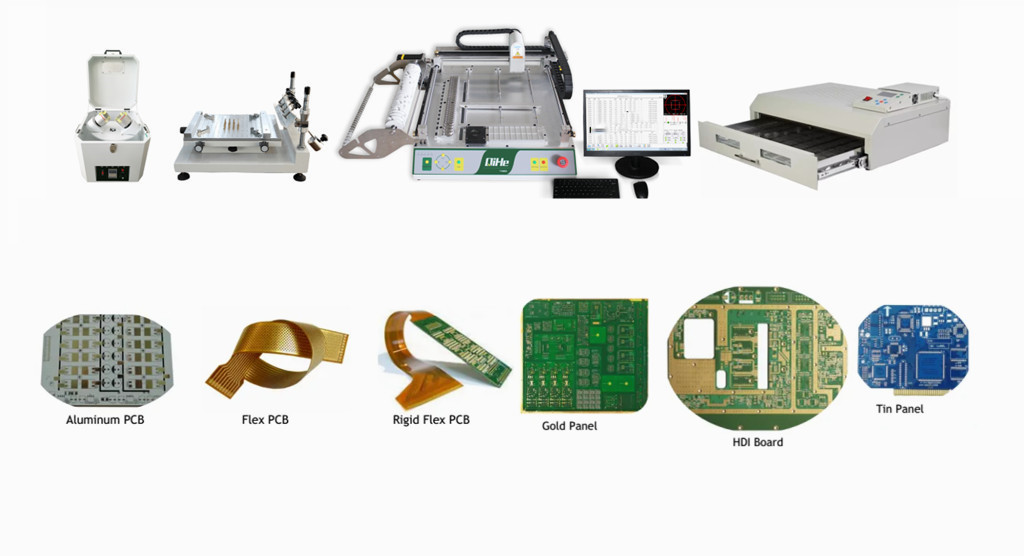

you can choose a reflow oven to meets your need like qfr630,qrf835,qrf1235

stencil printer model qh3040,qp3250,qfa5060

Also we have different kinds of smt pick and place machine like tvm802a,tvm802b,tvm802ax,tvm802bx,tvm925s,tvm926s,ql41,qm61,qm62,qm81,qm10

-

Q10 SMT Automatic pick and place machine 10 Heads 100 Slots High Precision and High Efficiency SMT/LED Assembly

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802BX SMT pick and place machine 2heads 46slots desktop pnp mounter deluxe edition

-

QL41 SMT pick and place machine 4heads 8slots LED for 1.2meters led strip pick&place machine

-

Q8 SMT pick and place machine 8heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802AX SMT pick and place machine 2heads 29slots desktop deluxe edition SMT Pick&Place Machine

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

WHAT IS SMT PROCESS?

There are mainly three steps in SMT assembly line process flow: solder paste printing, components placement and reflow soldering.

- Solder Paste Printing

Its function in SMT line process is to print the solder-free paste on the pads of the PCB to prepare for the soldering of the components. The equipment used is a screen printing machine, located at the forefront of the SMT production line.

- Components Placement

Its function is to accurately install the surface mount components on the fixed position of the PCB. The equipment used is a placement machine, located behind the screen printing machine in the SMT production line.

- Reflow Soldering

Its function in SMT manufacturing line is to melt the solder paste so that the surface mount components and the PCB board are firmly bonded together. The equipment used is a reflow oven, located behind the placement machine in the fully automatic SMT production line.