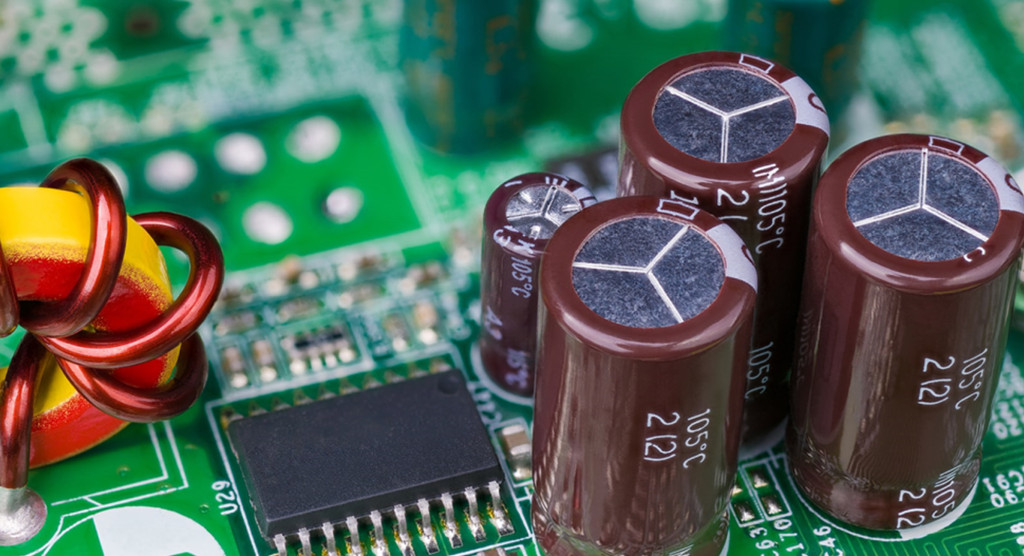

SMT processing plants are also very particular about the selection and use of electronic components. Among them, tantalum electrolytic capacitors have a larger unit volume capacity, so surface-mounted components with a capacity exceeding 0.33μF usually need to use this tantalum electrolytic capacitor. capacitor. The electrolyte response speed of tantalum electrolytic capacitors is much faster than that of ordinary capacitors, so tantalum electrolytic capacitors must be used in places that require high-speed computing processing. Tantalum electrolytic capacitors are usually suitable for application in consumer electronic devices due to their unique advantages in price.Next, author from qihe smt pick and place machine will take you to understand the reliable characteristics of tantalum electrolytic capacitors

a. Since tantalum electrolytic capacitors are sintered into porous positive electrodes with very fine particles in the SMT processing plant, the volumetric capacitance is particularly large, and the dielectric constant of the tantalum oxide film is larger than that of the aluminum oxide film, so Under the same working voltage and capacitance, the volume of tantalum electrolytic capacitors is much smaller than that of aluminum electrolytic capacitors.

b, the use of a wide temperature range. Generally, tantalum electrolytic capacitors can work in the temperature environment of -40℃~85℃, and some can even work normally at 155℃.

c, the leakage current is very small, the loss is relatively low, the insulation resistance is large, and the frequency characteristics are good.

d, the capacitance is large, the service life is long, and it can be made into ultra-small components, which is very convenient.

e. Due to the stable chemical properties of the tantalum oxide film and the acid and alkali resistance, the electrolytic capacitors have stable performance and can still maintain very good electrical properties after long-term operation.

f. Since the tantalum electrolytic capacitors in the SMT processing plant use tantalum metal materials and some reasons for the process, the cost is relatively high, and the natural price will be more expensive.

g. Tantalum electrolytic capacitors are polar capacitors with low working voltage.

Tantalum electrolytic capacitors in SMT processing plants are mainly used in occasions where the performance parameters of aluminum electrolytic capacitors are difficult to meet high requirements, such as military and civilian complete circuits that require capacitors to be small in size, large in capacity range, good in frequency and impedance characteristics, and high in product stability. . The electronic components that these products may use are more demanding. Therefore, we should also discuss with electronic engineers whether it is suitable for use when selecting components.

The above is the author from qihe smt pick and place machine wants to sharing with you. If there is some inappropriate content .I hope you can leave a message to tell me and communicate with each other.

you can choose a reflow oven to meets your need like qfr630,qrf835,qrf1235

stencil printer model qh3040,qp3250,qfa5060

Also we have different kinds of smt pick and place machine like tvm802a,tvm802b,tvm802ax,tvm802bx,tvm925s,tvm926s,ql41,qm61,qm62,qm81,qm10

Qihe smt pick and place machine catalog

-

Automatic Screen Printing Machine RSE High Efficiency high Power Printing PCB

-

R5 Automatic Screen Printing Machine 2024 new listing SMD Solder Paste Printing

-

Q10 SMT Automatic pick and place machine 10 Heads 100 Slots High Precision and High Efficiency SMT/LED Assembly

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

QP5060 automatic solder paste printer stencil printer machine screen printer machine

-

RF8835LS up8/down8 Zones Reflow Oven solder welding

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

-

Q8 SMT pick and place machine 8heads 80slots Fully Automatic Chip mounter SMT Assembly

-

QM61 SMT pick and place machine 6heads 63slots Fully Automatic Pick&place machine SMT Assembly chip mounter

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.

WHAT IS SMT PROCESS?

There are mainly three steps in SMT assembly line process flow: solder paste printing, components placement and reflow soldering.

- Solder Paste Printing

Its function in SMT line process is to print the solder-free paste on the pads of the PCB to prepare for the soldering of the components. The equipment used is a screen printing machine, located at the forefront of the SMT production line.

- Components Placement

Its function is to accurately install the surface mount components on the fixed position of the PCB. The equipment used is a placement machine, located behind the screen printing machine in the SMT production line.

- Reflow Soldering

Its function in SMT manufacturing line is to melt the solder paste so that the surface mount components and the PCB board are firmly bonded together. The equipment used is a reflow oven, located behind the placement machine in the fully automatic SMT production line.