There are some skills about heat dissipation of PCB circuit boards before you use the smt pick and place machine. qihe smt will sharing you some tips today .

Qhsmt Skills about heat dissipation of PCB circuit boards

For any electronic product, it is a very harmful thing to not be able to dissipate heat when it is hot, not only for the product but also for the human being. If you do not find a way to dissipate heat from electronic equipment, the temperature of the equipment will continue to rise, which will directly lead to the overheating of the components of the equipment. In severe cases, the components of the equipment will explode. Therefore, there must be a good treatment method for the heat dissipation of electronic PCB circuit boards. Let’s take a look at the technical points.

a. When designing the PCB, the project has a lot of uniform distribution of power. The reason for uniform distribution is that if the power is concentrated, it is easy to generate heat and difficult to dissipate heat, which in turn affects the circuit board. use. Therefore, it is recommended to avoid the concentration of hot spots on the PCB as much as possible when designing.

b. Design some components with high power consumption to places where it is easy to dissipate heat, and avoid the most central position as much as possible. Because the PCB circuit board will need to assemble a lot of components when it is assembled, if the components with high power consumption are installed in the most, then some small parts around it will also generate some heat, which will not dissipate the heat even more. Therefore, it is necessary to reasonably design those components with high power consumption in a position where it is easy to dissipate heat.

c. On the components, distinguish which ones have low calorific value, poor heat resistance, large calorific value and good heat resistance. For example, large-scale integrated circuits and power transistors have high heat generation and good heat resistance, and these should be designed to be placed downstream of the cold air flow. Such as electrolytic capacitors, small-scale integrated circuits and small transistors are those with low heat generation and poor heat resistance, which can be designed above the most of the cooling airflow.

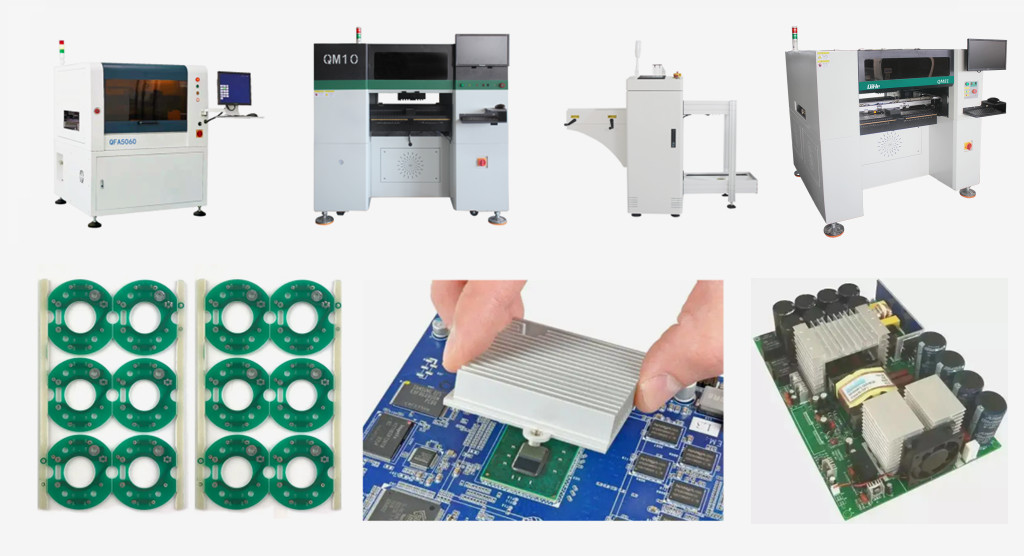

you can choose a reflow oven to meets your need like qfr630,qrf835,qrf1235

stencil printer model qh3040,qp3250,qfa5060

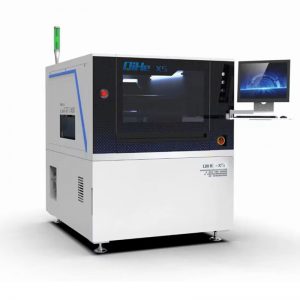

Also we have different kinds of smt pick and place machine like tvm802a,tvm802b,tvm802ax,tvm802bx,tvm925s,tvm926s,ql41,qm61,qm62,qm81,qm10

-

Automatic Screen Printing Machine RSE High Efficiency high Power Printing PCB

-

R5 Automatic Screen Printing Machine 2024 new listing SMD Solder Paste Printing

-

Q10 SMT Automatic pick and place machine 10 Heads 100 Slots High Precision and High Efficiency SMT/LED Assembly

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

QP5060 automatic solder paste printer stencil printer machine screen printer machine

-

RF8835LS up8/down8 Zones Reflow Oven solder welding

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

-

Q8 SMT pick and place machine 8heads 80slots Fully Automatic Chip mounter SMT Assembly

-

QM61 SMT pick and place machine 6heads 63slots Fully Automatic Pick&place machine SMT Assembly chip mounter

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

WHAT IS SMT PROCESS?

There are mainly three steps in SMT assembly line process flow: solder paste printing, components placement and reflow soldering.

- Solder Paste Printing

Its function in SMT line process is to print the solder-free paste on the pads of the PCB to prepare for the soldering of the components. The equipment used is a screen printing machine, located at the forefront of the SMT production line.

- Components Placement

Its function is to accurately install the surface mount components on the fixed position of the PCB. The equipment used is a placement machine, located behind the screen printing machine in the SMT production line.

- Reflow Soldering

Its function in SMT manufacturing line is to melt the solder paste so that the surface mount components and the PCB board are firmly bonded together. The equipment used is a reflow oven, located behind the placement machine in the fully automatic SMT production line.