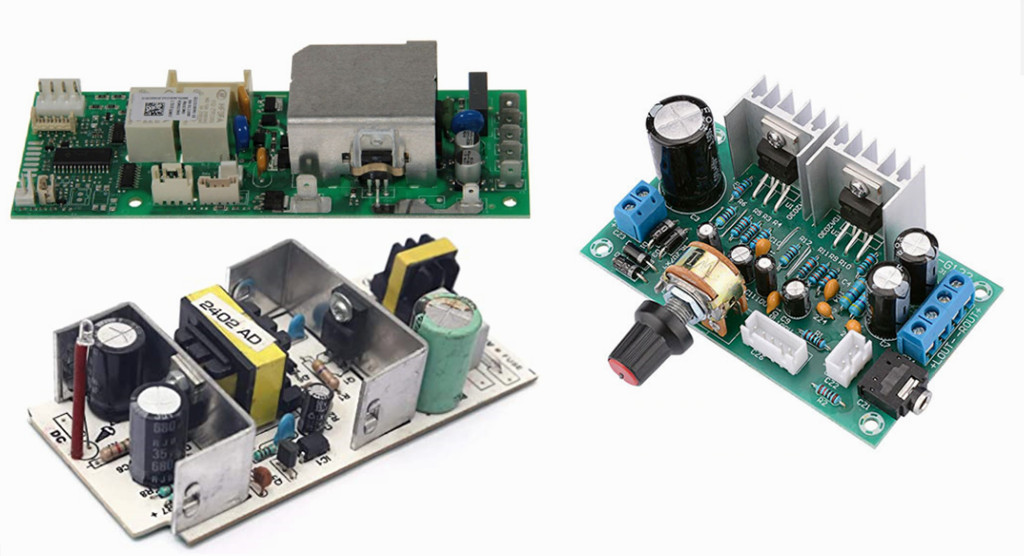

Compared with other types of circuit boards, the requirements of power circuit boards are high reliability and special copper thickness requirements. And these two points are difficult to control for circuit board manufacturers, so how to produce high-reliability power circuit boards?Next, author from qihe smt pick and place machine will take you to understand described from the following four aspects:

a. In terms of material selection: the power circuit board requires high stability, so in terms of material selection, attention should be paid to the selection of medium and high TG plates.

b. Control of copper thickness: Under the same line width design, the thicker the copper (that is, 2OZ thicker than 1OZ), the greater the current it can carry, so the power circuit board has special requirements for copper thickness, according to the application of the power circuit board. Different fields have different copper thickness requirements.

c. Control of ink thickness: For thick copper power circuit boards, the circuit is easy to expose copper and turn red, so it is necessary to do two solder masks to thicken the thickness of the green oil.

d. Quality control: The high reliability of power circuit boards requires stricter quality control, including AOI of the inner layer, copper thickness test of electroplating, AOI of the outer layer, electrical performance test, reliability test, etc. The management and control of a link are interlinked and indispensable.

The above is author from qihe smt pick and place machine wants to sharing with you. If there is some inappropriate content .I hope you can leave a message to tell me and communicate with each other.

you can choose different kinds of smt pick and place machine like tvm802a,tvm802b,tvm802ax,tvm802bx,tvm925s,tvm926s,ql41,qm61,qm62,qm81,qm10

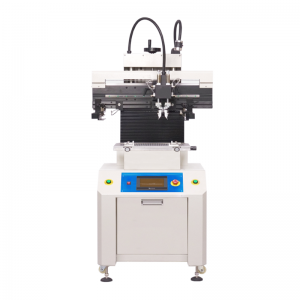

stencil printer model qh3040,qp3250,qfa5060

Also we have reflow oven to meets your need like qfr630,qrf835,qrf1235

Qihe smt pick and place machine catalog

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

QL41 SMT pick and place machine 4heads 8slots LED for 1.2meters led strip pick&place machine

-

TVM926S (customized model) SMT pick and place machine 4heads 63slots With Rail Benchtop Pick&Place Machine

-

TVM925S (customized model) SMT pick and place machine 4heads 50slots With Rail Benchtop SMT Pick&Place Machine

-

QRF320 / QH320 Crawler-type 5 Zones SMT Reflow Oven solder welding

-

QP1068S Semi Automatic Stencil Printing 1.2meters

-

QP3250 Semi Automatic Stencil Printing 0.5meter

FAQ about smt pick and place machine

WHAT IS SMT pick and place machine?

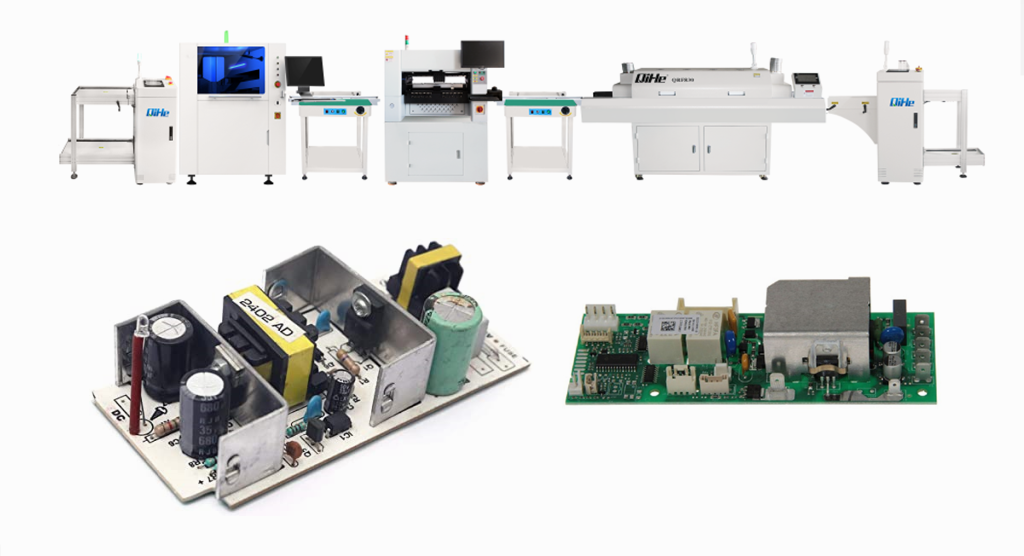

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

WHAT IS SMT PROCESS?

There are mainly three steps in SMT assembly line process flow: solder paste printing, components placement and reflow soldering.

- Solder Paste Printing

Its function in SMT line process is to print the solder-free paste on the pads of the PCB to prepare for the soldering of the components. The equipment used is a screen printing machine, located at the forefront of the SMT production line.

- Components Placement

Its function is to accurately install the surface mount components on the fixed position of the PCB. The equipment used is a placement machine, located behind the screen printing machine in the SMT production line.

- Reflow Soldering

Its function in SMT manufacturing line is to melt the solder paste so that the surface mount components and the PCB board are firmly bonded together. The equipment used is a reflow oven, located behind the placement machine in the fully automatic SMT production line.