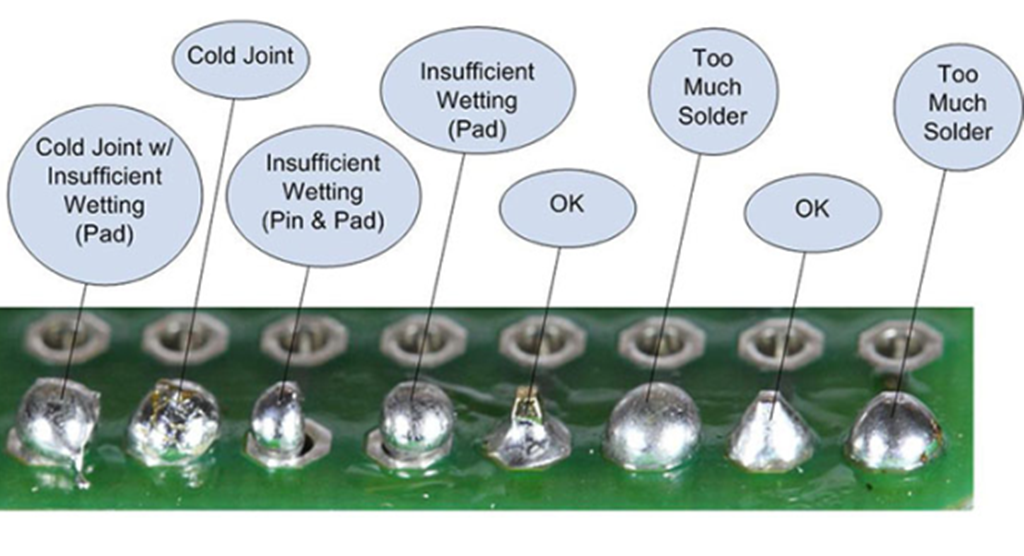

In reflow oven patch processing after we finished the smt pick and place machine mounting process, some quality problems often occur, such as: cold joint, bridges, insufficient wetting, too much tin/less tin, what is the reason for this reflow soldering? how to solve it,

The following Qhsmt technology will be explained to you.

One . Parts drift – reasons: 1. The two ends of the parts are heated unevenly. 2. One end of the part does not eat tin well.

Solution: 1. The reflow adopts a saddle type and prolongs the preheating (150~170℃) time. 2. Make sure the parts and PCB pads are free from oxidation.

- Confirm that the solder coating of the part is compatible with the composition of the solder paste.

Two: Short circuit between BGA solder balls and solder balls—-reasons 1. Too much solder paste 2. Solder paste printing offset 3. Solder paste collapse 4. Squeegee pressure is too small 5. The gap between the steel plate and the circuit board is too large

Solution: 1. Reduce the amount of solder paste printing (reduce the thickness of the steel plate, reduce the opening of the steel plate). 2. Adjust the alignment accuracy of the steel plate. 3. Confirm that the precision of the circuit board assembly meets the requirements. 4. Adjust the Reflow curve. 5. Confirm the quality of solder paste. 6. Increase the pressure and speed of the scraper. 7. Check that the tension of the steel plate meets the regulations and there is no deformation. 8. Check that the thickness of the solder mask and silk screen layer conforms to the regulations

Three: empty welding or pillow effect

Reasons: 1. The amount of solder paste is too small 2. The solder balls do not touch tin 3. Vias-in-pad 4. The circuit board solder pads do not eat tin 5. BGA or PCB high temperature deformation Inconsistent or uneven size

Solution:

- Increase the thickness of the steel plate or increase the opening. 2. Check whether the solder balls are oxidized. 3. Change the design to fill holes or increase the amount of tin. 4. Check whether the pad is oxidized on the circuit board. 5. Slow down the heating rate, increase the amount of tin, and use a furnace carrier. 6. Review the opening of the steel plate and the printing parameters of the solder paste

Four: Air Soldering – Reasons 1. The feet of the parts are not flat 2. The amount of solder paste is too small 3… The feet of the parts do not eat tin

Solution: 1. Confirm that the flatness of the foot of the part meets the regulations. 2. Increase the thickness of the steel plate or increase the opening. 3. Decrease the heating rate of Reflow or review the tin-eating property of the parts with the supplier. 4. Check whether the foot of the part is oxidized. 5. Change the design to avoid holes when filling holes or solder paste printing. 6. Check whether the circuit board pads are oxidized

Five: Air welding of footless SMD parts

Reasons: 1. Improper design of solder pads 2. Uneven heating at both ends of solder pads 3. Too little solder paste 4. Poor tin consumption of parts

Solution: 1. Check whether the feet of the parts connected to the large-area copper foil on the circuit board dissipate too fast, so that the heating rate cannot keep up with other solder feet. 2. Slow down the heating rate of the temperature curve or the pad size of the same part should be consistent. 3. Increase the amount of solder paste 4. The parts must meet the needs of eating tin

Six: Tombstone/Tombstone – Reasons 1. Inconsistent heating speed at both ends of the pad, improper design of the pad 2. Different tin eating at both ends of the pad 3. Uneven heating at both ends of the pad 4. The reflow temperature is heated too fast

Solution:

- Increase thermal resistance. 2. Slow down the heating rate of the temperature profile 3. Preheat to 170°C before reflow soldering

Seven: Cold Welding – The Reason

- The reflow soldering temperature is too low 2. The reflow soldering time is too short 3. The tin-eating problem of the pins

Solution 1. Increase the peak reflow temperature to 245℃~255℃. 2. Extend the reflow soldering time (>220℃ above at least 40-60 seconds)

you can choose a reflow oven to meets your need like qfr630,qrf835,qrf1235

Also we have different kinds of smt pick and place machine like tvm802a,tvm802b,tvm802ax,tvm802bx,tvm925s,tvm926s,ql41,qm61,qm62,qm81,qm10

-

RF8835LS up8/down8 Zones Reflow Oven solder welding

-

QRF320 / QH320 Crawler-type 5 Zones SMT Reflow Oven solder welding

-

QR962C Desktop SMT Reflow Oven solder welding

-

QRF1235 12 Zones SMT Reflow Oven solder welding with guide rail

-

QRF830 8 Zones SMT Reflow Oven solder welding with cabinet

-

QRF835 with rail 8 Zones SMT Reflow Oven solder welding

-

QRF1230 12 Zones SMT Reflow Oven solder welding with cabinet

-

QRF630 6 Zones SMT Reflow Oven solder welding with cabinet

-

Automatic Screen Printing Machine RSE High Efficiency high Power Printing PCB

-

R5 Automatic Screen Printing Machine 2024 new listing SMD Solder Paste Printing

-

Q10 SMT Automatic pick and place machine 10 Heads 100 Slots High Precision and High Efficiency SMT/LED Assembly

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

QP5060 automatic solder paste printer stencil printer machine screen printer machine

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

RF8835LS up8/down8 Zones Reflow Oven solder welding

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.

WHAT IS SMT PROCESS?

WHAT IS SMT PROCESS?

There are mainly three steps in SMT assembly line process flow: solder paste printing, components placement and reflow soldering.

- Solder Paste Printing

Its function in SMT line process is to print the solder-free paste on the pads of the PCB to prepare for the soldering of the components. The equipment used is a screen printing machine, located at the forefront of the SMT production line.

- Components Placement

Its function is to accurately install the surface mount components on the fixed position of the PCB. The equipment used is a placement machine, located behind the screen printing machine in the SMT production line.

- Reflow Soldering

Its function in SMT manufacturing line is to melt the solder paste so that the surface mount components and the PCB board are firmly bonded together. The equipment used is a reflow oven, located behind the placement machine in the fully automatic SMT production line.