To operate smt pick and palce machine QM61 pnp file programming, it must be turned on according to the operating procedures to ensure personal and equipment safety. QHSMT tech will briefly describe the steps for starting the placement IC mounter:

Proceed as follows:

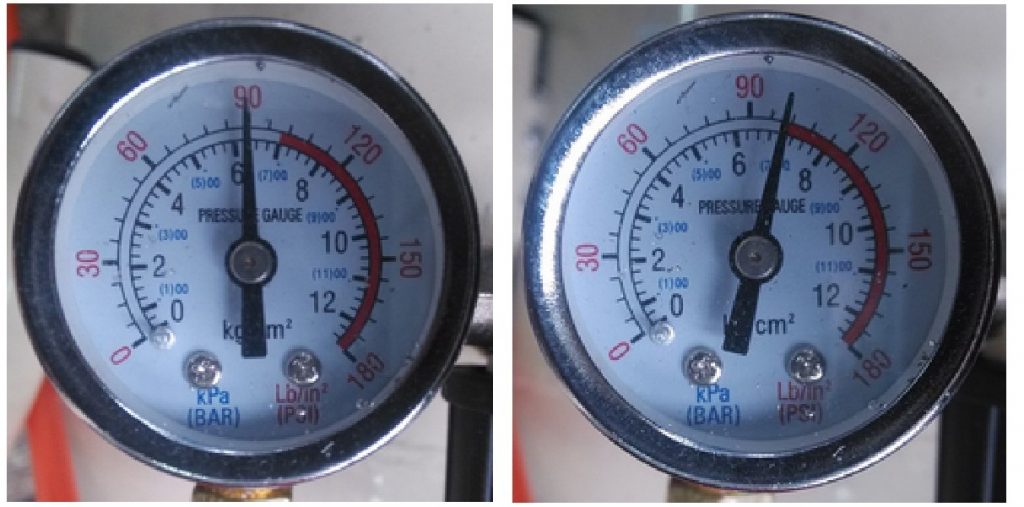

- Check whether the air pressure of the placement machine meets the equipment requirements, generally it should be about 5kg/cm2.

- Turn on the system.

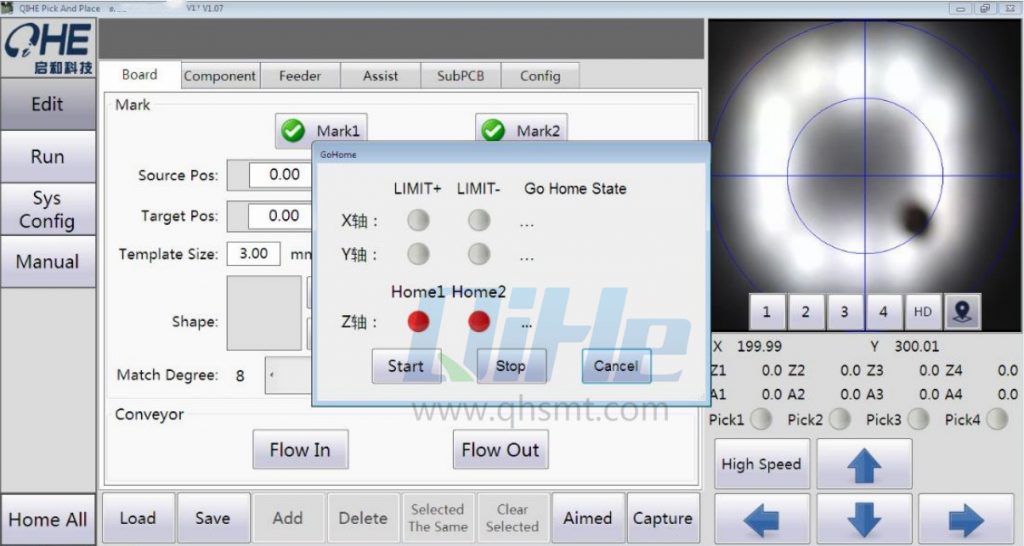

- Return all axes of the placement machine to the origin.

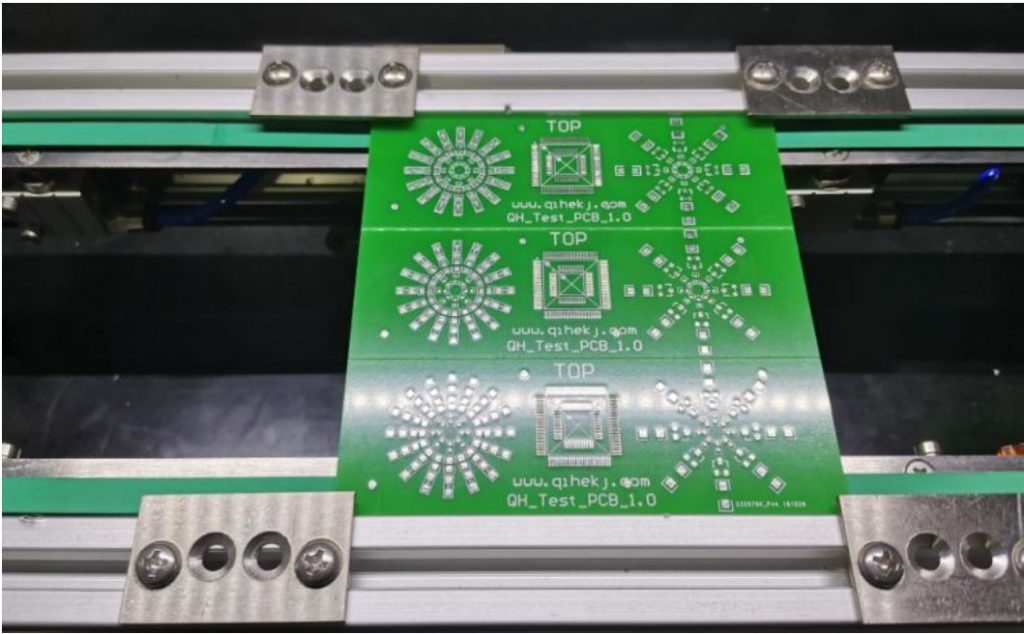

- Adjust the width of the placement machine guide rail to be about 1mm greater than the width of the PCB, and ensure that the PCB slides freely on the guide rail.

- Set up and install the PCB positioning device. Generally, there are two methods of needle positioning and edge positioning.

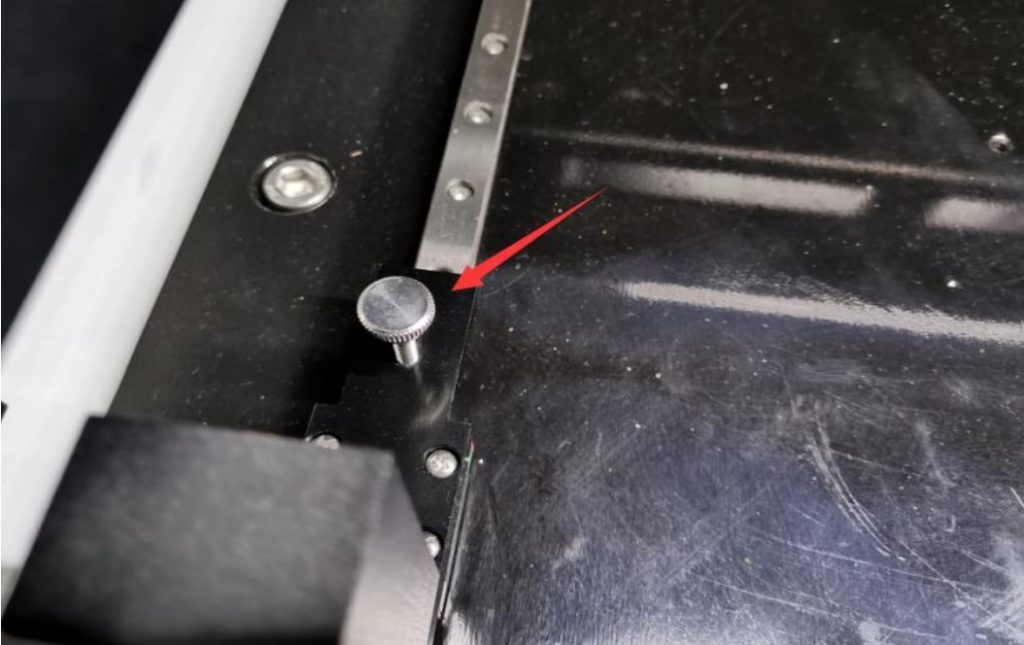

Needle positioning method:

When using needle positioning, adjust the position of the positioning needle so that the positioning needle is just in the middle of the positioning hole of the PCB, so that the PCB can be positioned up and down freely.

Edge positioning method:

Place the PCB support thimble according to the thickness and external dimensions of the PCB to ensure that the PCB is evenly stressed and not loose during patching. If it is a double-sided mounting PCB, after the B side is mounted, the position of the PCB support thimble must be readjusted to ensure that when the A side is mounted, the PCB support pin avoids the mounted components on the B side.

- After the setting is completed, the PCB can be installed for online programming or patch operation.

The above are the steps and precautions for starting the placement machine. After the startup is completed, it is necessary to program the placement of the placement machine.

The placement program consists of a pickup program and a placement program.

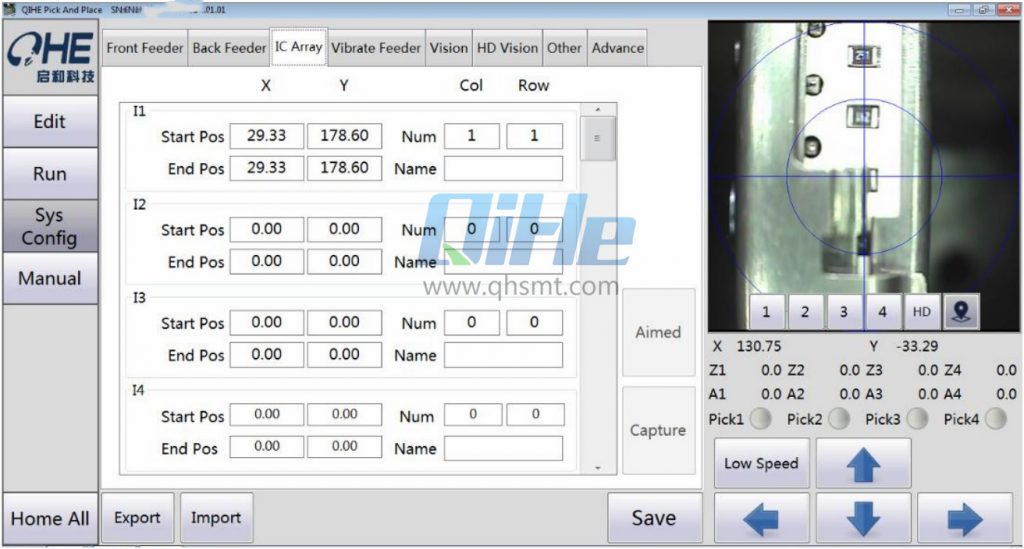

- Pickup program

The pickup program tells the placement machine where to pick up the piece and what kind of component information to pick up. The content includes: the component name of each step, the offset of X, Y and corner of the pick-up in each step, the position of the feeder, the type of the feeder, the height of the pick-up, the position of the material to be thrown, whether to skip, etc. .

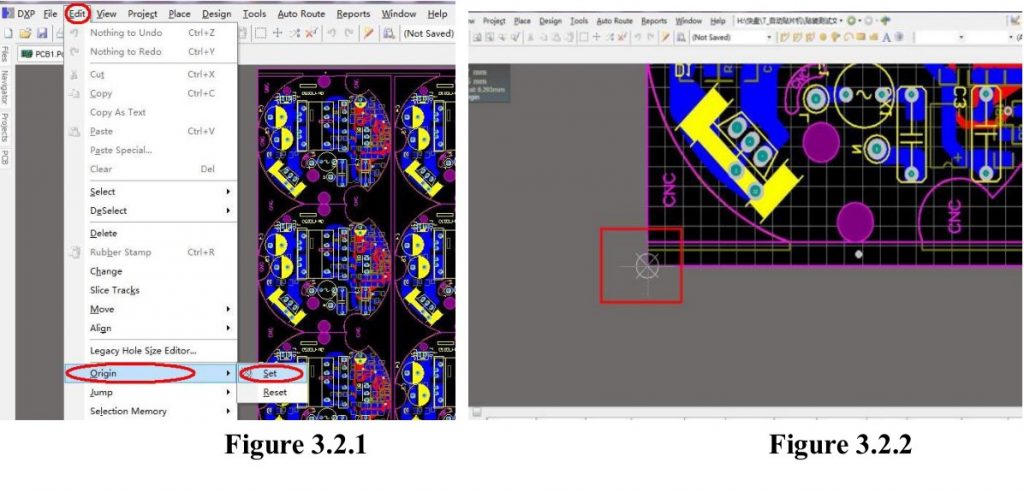

- Placement Patch program

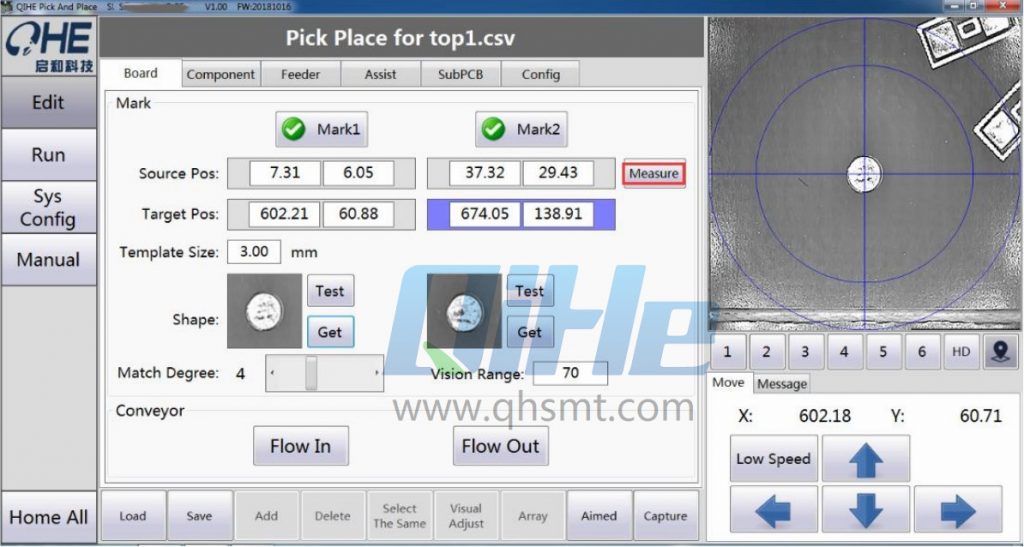

The placement program tells the machine where to place the components, the angle of the placement, the height of the placement, etc.

The content includes the component name of each step, the X, y coordinates and corners of each step, whether the height of the patch needs to be corrected, the number of the patch head to be patched, whether multiple heads are picking up at the same time, whether to skip steps, etc.: patch program It also includes X, y coordinate information of PCB and local Mark, etc.

The placement machine engineer operator can understand machine repair, shift scheduling, placement programming, and then be proficient in operating various SMT pick and place machines and SMT production lines during the processing process

you can find a set of smt pick and place machine you need ,we have lots of series for you to choose.

-

Professional PCB external pumping type inflatable vacuum packaging machine, moisture-proof and anti-oxidation, guarding the quality of circuit boards

-

Professional PCB external vacuum packaging machine , moisture-proof and anti-oxidation, protecting the quality of circuit boards

-

High – Precision Offline PCBA Cleaner QH-800: Remove Stubborn Flux Residue Completely

-

Intelligent 3D Monorail SPI QS400, powered by AI, automatically identifies and analyzes solder paste printing problems!

-

SPI-QS800 Ultra Precise In line Single Track : Detect Tin Paste Defects with Micron – Level Accuracy

-

Offline 2D AOI, PCB, FPC universal inspection tool, to meet the needs of diversified production

-

Online 2D AOI: Real – Time Precision for Continuous SMT Production

-

QH-VVL360 Rapid 3D Imaging for Lightning – Fast SMT Defect Detection

-

Automatic Screen Printing Machine RSE High Efficiency high Power Printing PCB

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

WHAT IS SMT pick and place machine?

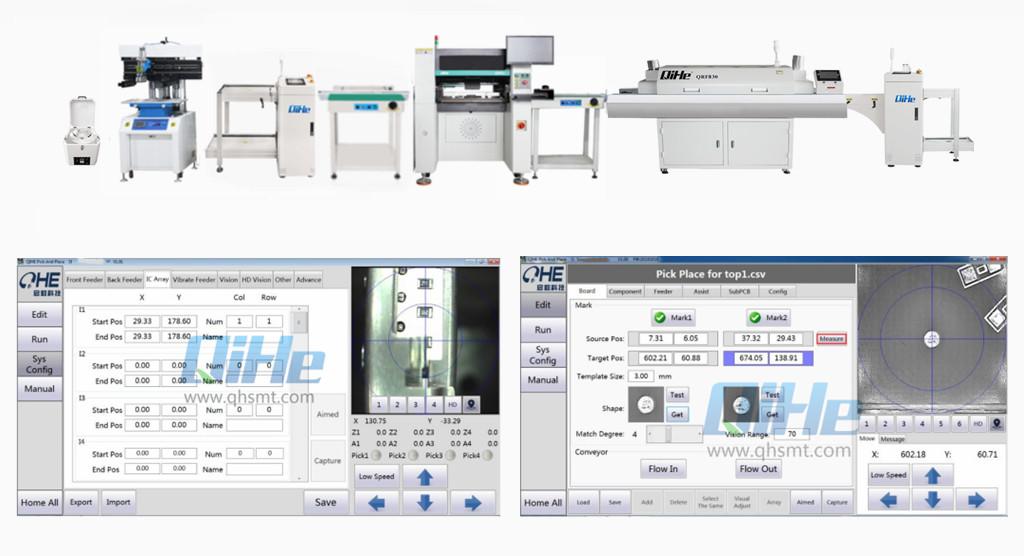

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, connecting table, etc. For these SMT assembly line equipment, Qihe smt can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.

WHAT IS SMT PROCESS?

There are mainly three steps in SMT assembly line process flow: solder paste printing, components placement and reflow soldering.

- Solder Paste Printing

Its function in SMT line process is to print the solder-free paste on the pads of the PCB to prepare for the soldering of the components. The equipment used is a screen printing machine, located at the forefront of the SMT production line.

- Components Placement

Its function is to accurately install the surface mount components on the fixed position of the PCB. The equipment used is a placement machine, located behind the screen printing machine in the SMT production line.

- Reflow Soldering

Its function in SMT manufacturing line is to melt the solder paste so that the surface mount components and the PCB board are firmly bonded together. The equipment used is a reflow oven, located behind the placement machine in the fully automatic SMT production line.